Sealed type direct current contactor with high breaking capacity

A DC contactor, sealed technology, used in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of contact wear, can not be prevented, long arcing time, etc., to reduce wear, improve service life, improve Effects of insulating properties and protective capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

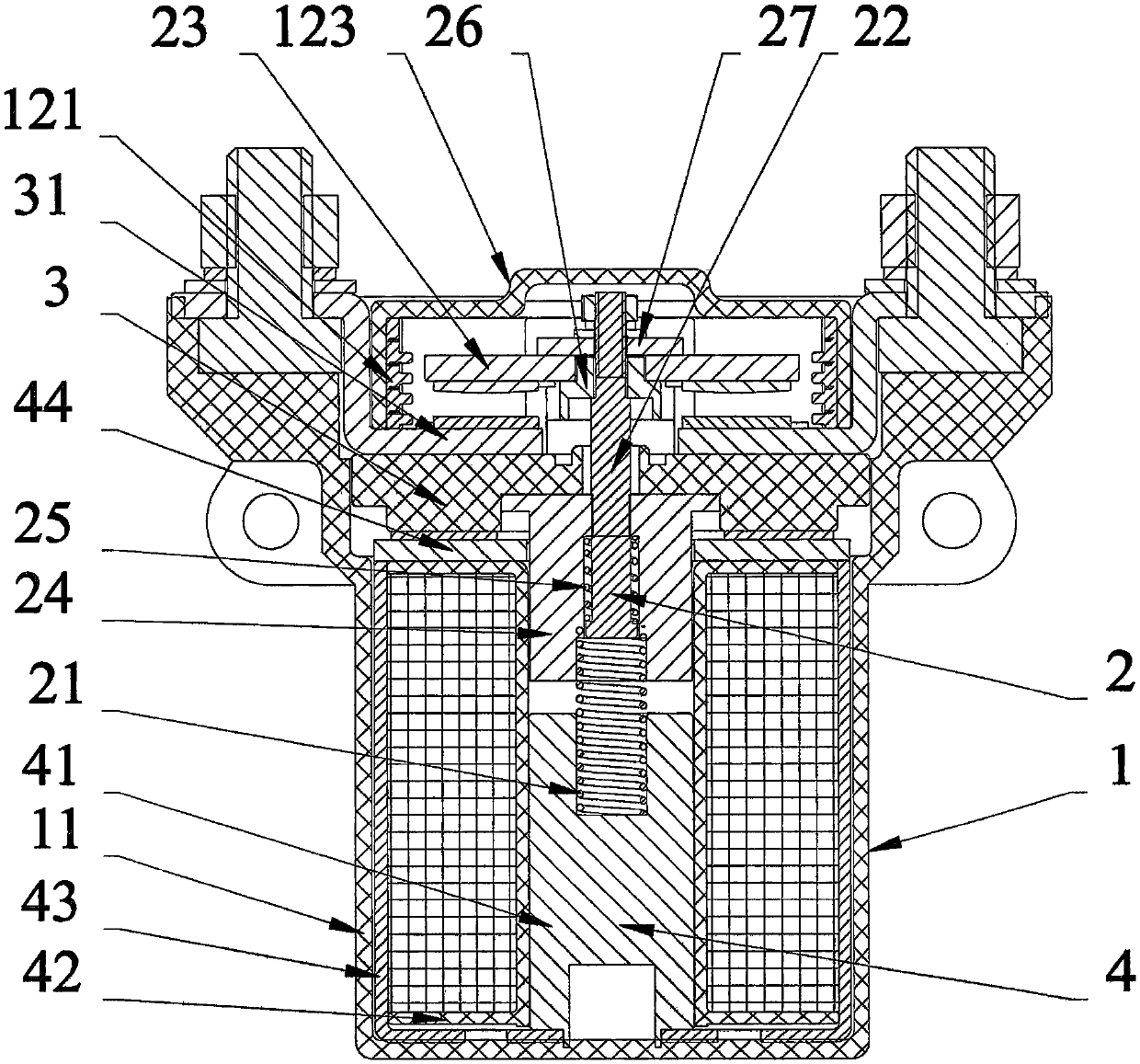

[0044] Attached figure 1 And attached figure 2 As shown, a sealed DC contactor with high breaking capacity. The external structure 1 includes a housing 11 and an arc extinguishing cover 12 .

[0045] The action system 2 includes a reaction force spring 21 , a push rod 22 , a bridge terminal assembly 23 and a moving iron core 24 .

[0046] The contact system 3 comprises a contact assembly 31 .

[0047] The magnetic circuit system 4 includes a static iron core 41 and an electromagnetic coil 42 .

[0048] The reaction force spring 21 and the bridge terminal assembly 23 are installed on the lower end and the upper end of the push rod 22 respectively; the moving iron core 24 is installed inside the electromagnetic coil 42 and connected with the push rod 22 .

[0049] The contact assembly 31 is fixed above the electromagnetic coil 42 .

[0050] Static iron core 41 is installed on push rod 22 lower ends.

[0051] The casing 11 and the arc extinguishing cover 12 form a sealed c...

Embodiment 2

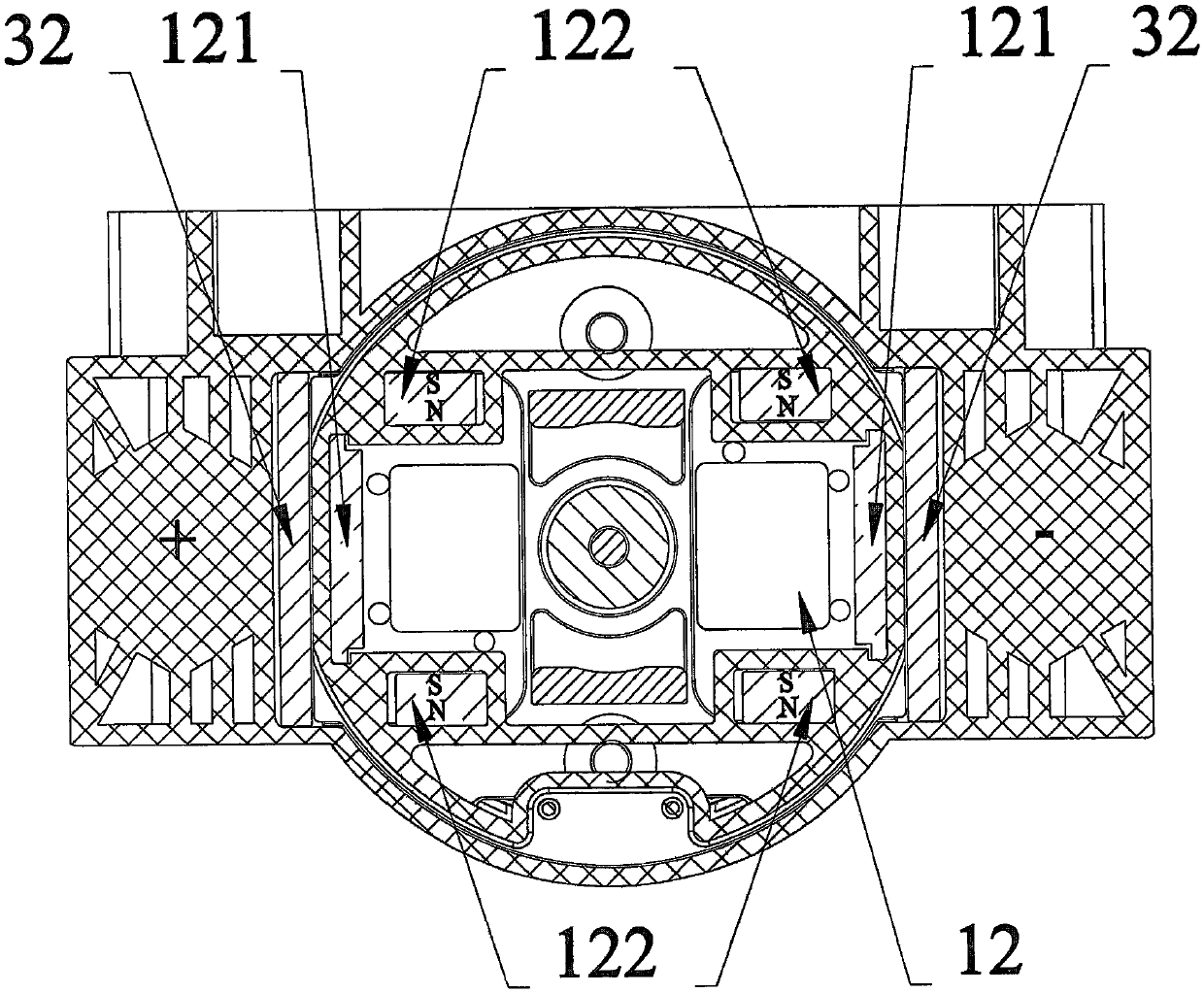

[0055] On the basis of embodiment one, as attached figure 2 As shown, there are 2 pairs of permanent magnets 122, each pair is respectively fixed on both sides of the upper cover 123, and the N poles of one pair of permanent magnets 122 point in the opposite direction, and the N poles on the same side point in the same direction.

Embodiment 3

[0057] On the basis of embodiment two, as attached figure 1 As shown, the actuation system 2 includes a contact spring 25 . The upper end of the contact spring 25 is connected to the bottom of the bridge terminal assembly 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com