Laminated tube

An aliphatic polyamide, polyamide technology, applied in the direction of pipes, rigid pipes, layered products, etc., can solve problems such as insufficient penetration resistance, and achieve the effects of improved durability, high utilization value, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

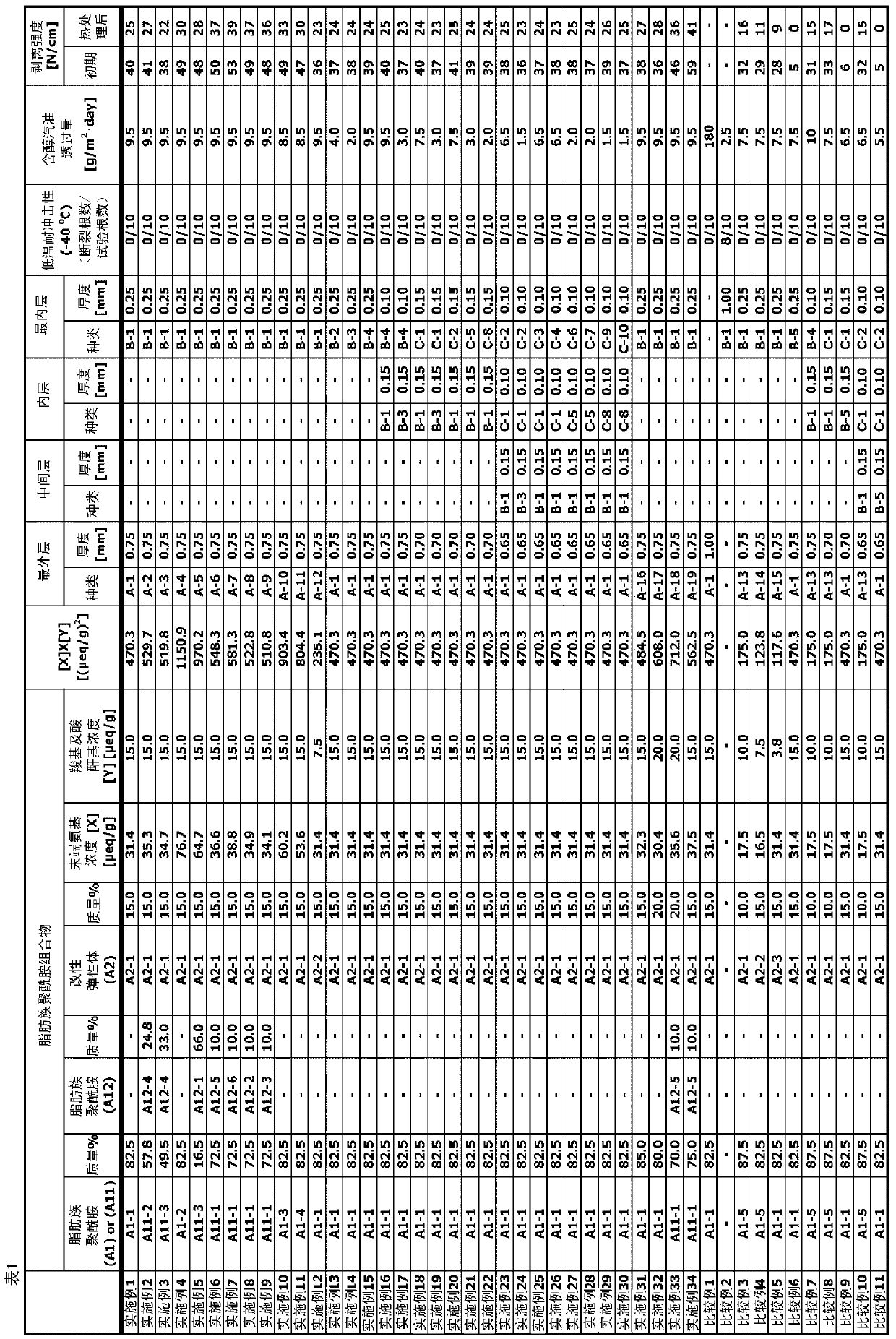

Examples

Embodiment 1

[0359] Using the polyamide 12 composition (A-1) and the semi-aromatic polyamide composition (B-1) shown above, the (A-1 ) at an extrusion temperature of 270° C. and (B-1) at an extrusion temperature of 300° C. were melted separately, and the discharged molten resins were combined by an adapter (adapter) to form a laminated tubular body. Next, it is cooled by a sizing die for size control, and then retrieved (引き拍り) to obtain (a) layer (outermost layer) containing (A-1) and (b) layer (b) containing (B-1). In the case of the innermost layer), the layer configuration is (a) / (b) = 0.75 / 0.25 mm, a laminated tube with an inner diameter of 6 mm and an outer diameter of 8 mm. Table 1 shows the measurement results of physical properties of the laminated tube.

Embodiment 2

[0361] In Example 1, except having changed the polyamide 12 composition (A-1) into (A-2), the laminated tube of the layer structure shown in Table 1 was obtained by the method similar to Example 1. Table 1 shows the measurement results of physical properties of the laminated tube.

Embodiment 3

[0363] In Example 1, except having changed the polyamide 12 composition (A-1) into (A-3), the laminated|multilayer tube of the layer structure shown in Table 1 was obtained by the method similar to Example 1. Table 1 shows the measurement results of physical properties of the laminated tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com