Filter disc directed at XRF element determination and preparation method thereof, determination box, and element determination method

A technology of element determination and determination box, which is applied in the field of element determination and determination box, which can solve the problems that the instrument cannot give accurate and reliable measurement results, large matrix effect, and huge difference in test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

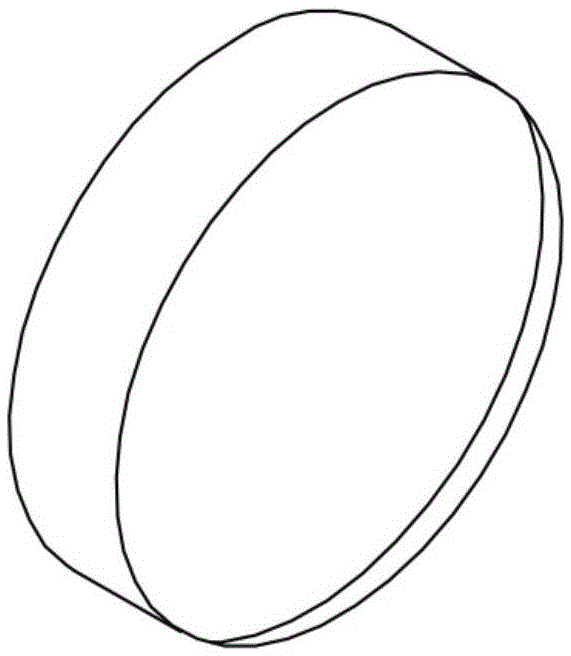

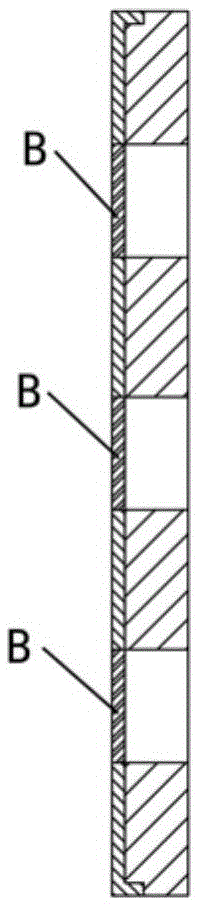

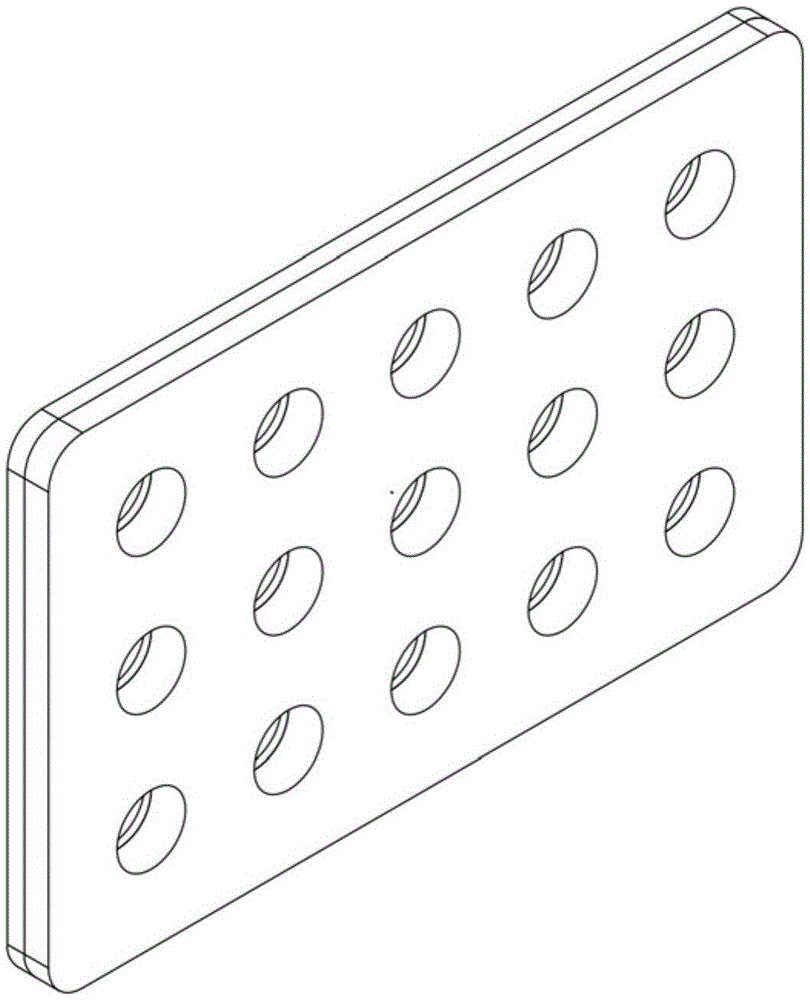

[0027] A filter preparation method for XRF element determination, comprising:

[0028] Take solutions of various concentrations of elements to be tested (including but not limited to standard solutions, or solutions after dissolving high-purity products) on the carrier, and dry them to obtain original filter pieces, and make the original filter pieces A final filter whose size matches the substance to be measured, wherein the standard solution of one or more elements to be measured is placed on the carrier, and the carrier is stearic acid, cellulose, filter paper, boric acid, starch, One or more of alcohol, triethanolamine, the final filter is sealed by a sealing material, wherein the sealing material is a plastic film, such as polyethylene film, polypropylene film, etc., wherein the solution is passed through Alcohol and triethanolamine are mixed and then mixed with the carrier, or the solution is directly mixed with the carrier, the carrier is mixed with the solid high-purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com