Preparation method of frozen yoghourt

A technology for freezing yogurt and lactic acid bacteria, which is applied in milk preparations, dairy products, applications, etc., can solve problems such as instability of yogurt, and achieve the effects of ensuring taste and stability, improving stability, and good emulsifying and gelling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

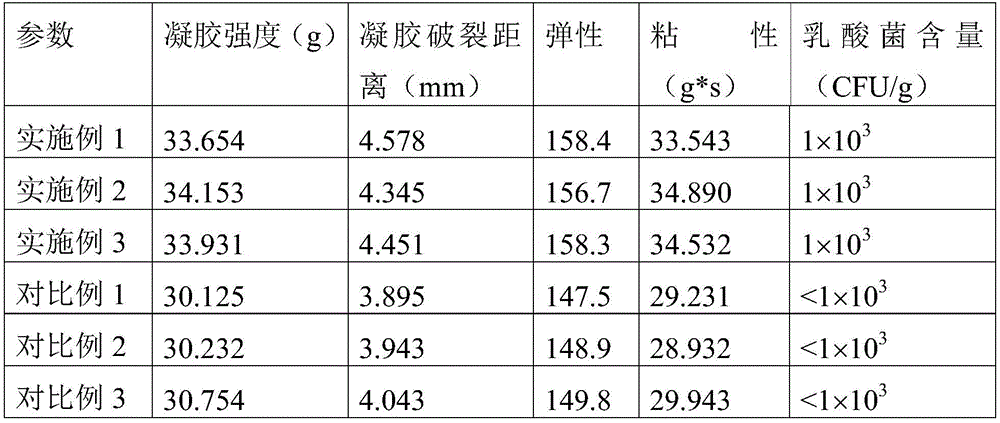

Examples

preparation example Construction

[0028] The invention provides a method for preparing frozen yoghurt, comprising the following steps:

[0029] S1, adding the first composite stabilizer, sweetener, and whey protein powder to the preheated and sterilized fresh milk, and stirring evenly to form a composite milk mixture;

[0030] S2, preheating and homogenizing the composite emulsion mixture obtained in step S1;

[0031] S3, sterilizing the homogenized compound emulsion mixture in a water bath at a temperature of 100-105° C. for 4-5 minutes, and cooling to a temperature of 40-45° C.;

[0032] S4, inoculating lactic acid bacteria to the cooled compound milk mixture, and carrying out the first fermentation;

[0033] S5, continue to add the sterilized second composite stabilizer and lactic acid bacteria to the composite milk mixture after the first fermentation, and perform the second fermentation to obtain yogurt;

[0034] S6, stirring, aseptically preserving and filling the yogurt after the second fermentation; ...

Embodiment 1

[0045] The present embodiment provides a kind of preparation method of frozen yoghurt, comprises the following steps:

[0046]S1, adding the first composite stabilizer, sweetener, and whey protein powder to the preheated and sterilized raw milk, stirring evenly to form a composite milk mixture; S2, preheating and homogenizing the composite milk mixture Treatment; preheating temperature is 55-60°C, time is 20 minutes; homogeneous pressure is 20-25Mpa, time is 10 minutes; S3, sterilized at 100-105°C in water bath for 4-5 minutes, cooled to a temperature of 40 -45°C; S4, inoculate lactic acid bacteria into the cooled compound milk mixture, carry out the first fermentation at a temperature of 41-42°C, and the fermentation time is 7-8 hours; S5, continue to add the second compound stabilizer and lactic acid bacteria, After the second fermentation at a temperature of 2-7°C, the fermentation time is 4-5 hours to obtain yogurt; S6, stirring, aseptically preserving and filling the yogu...

Embodiment 2

[0049] The present embodiment provides a kind of preparation method of frozen yoghurt, comprises the following steps:

[0050] S1, adding the first composite stabilizer, sweetener, and whey protein powder to the preheated and sterilized raw milk, stirring evenly to form a composite milk mixture; S2, preheating and homogenizing the composite milk mixture Treatment; preheating temperature is 55-60°C, time is 20 minutes; homogeneous pressure is 20-25Mpa, time is 10 minutes; S3, sterilized at 100-105°C in water bath for 4-5 minutes, cooled to a temperature of 40 -45°C; S4, inoculate lactic acid bacteria into the cooled compound milk mixture, carry out the first fermentation at a temperature of 41-42°C, and the fermentation time is 7-8 hours; S5, continue to add the second compound stabilizer and lactic acid bacteria, After the second fermentation at a temperature of 2-7°C, the fermentation time is 4-5 hours to obtain yogurt; S6, stirring, aseptically preserving and filling the yog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com