Method and device for eliminating stress of metal die underwater

A metal mold and mold technology, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems such as the thickness and uniformity of light-absorbing paint are difficult to control, the residual paint on the surface of the workpiece is difficult to clean, and the surface of the workpiece is prone to over-melting. Achieve the effect of good stress relief, low processing cost and enhanced rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

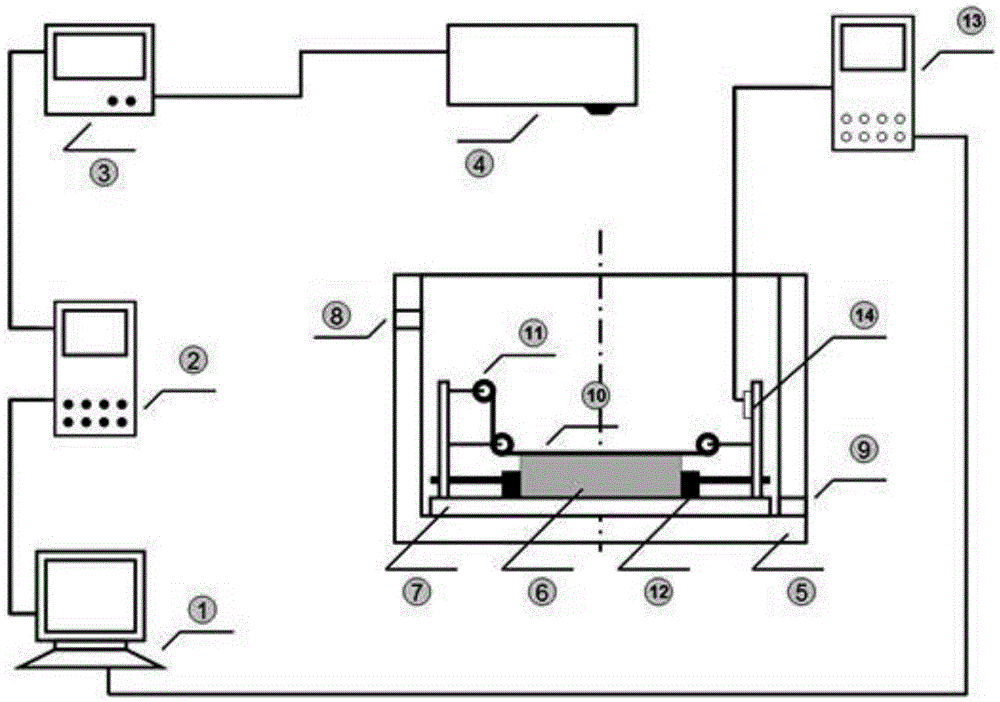

[0020] In order to clearly express the characteristics of the application steps of the method and device application steps of an underwater metal mold stress relief method of the present invention, a specific embodiment will be described in detail below in conjunction with the accompanying drawings.

[0021] 1. Make a laser absorbing film (10) of corresponding width, thickness and density according to the material and processing requirements of the mold (6);

[0022] 2. According to the processing requirements of the mold (6), the workbench control program is compiled to control the movement path of the workbench (7);

[0023] 3. Install the mold (6) on the fixture, install the laser absorbing film (10) on the absorbing film rolling system (11), inject water into the water tank (5) and keep the thickness of the water layer above the surface of the mold (6) to be treated constant;

[0024] 4. Set the laser spot size, laser power, laser pulse width and other parameters accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com