Single-degree-of-freedom movement polycyclic symmetrical coupling mechanism

A technology of coupling mechanism and degrees of freedom, applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large working space, inconvenient transportation and execution, incompetent volume and lightness of the series mechanism, and achieves good application prospects and high rigidity. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

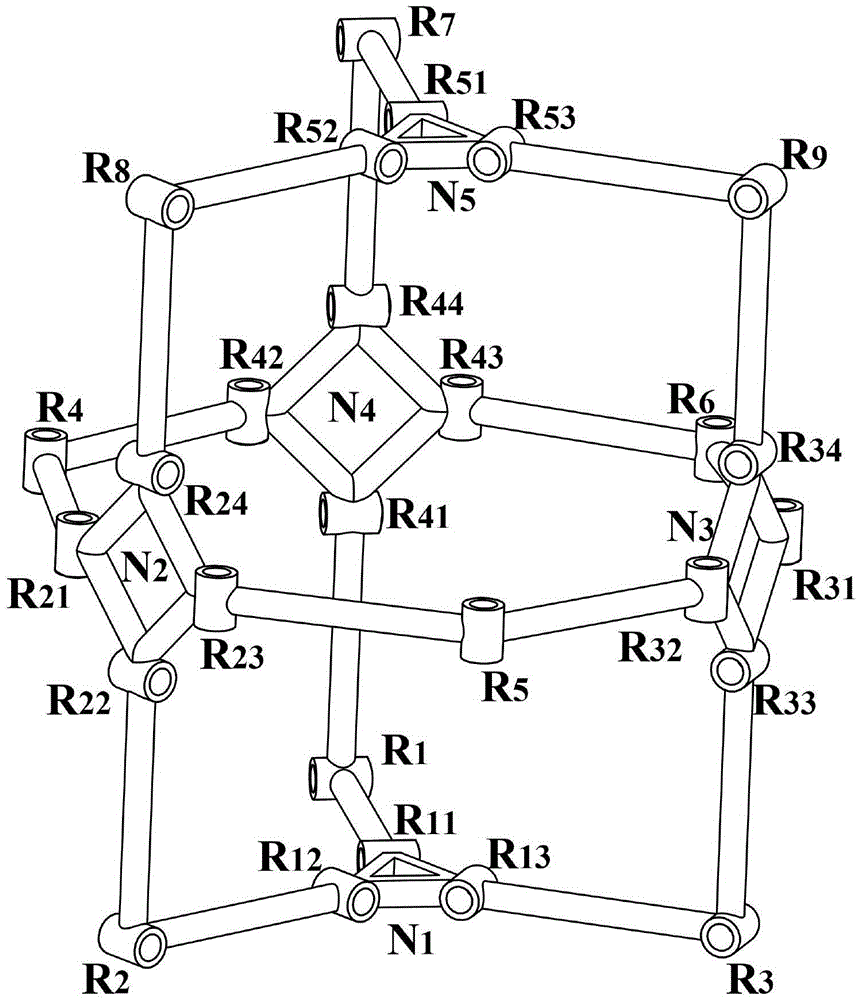

[0018] Such as figure 2 As shown, the first branch includes the first revolving pair (R11) of the frame, the first rod group (L1), the first revolving pair (R41) of node member one, the fourth revolving pair (R44) of node member one, The seventh rod group (L7), the first rotating pair of the moving platform (R51); the first rod group (L1) is connected to the frame (N1) through the first rotating pair (R11) of the frame, and the first rod group (L1 ) is connected with the node member one (N4) through the first revolving pair (R41) of the node member one, and the seventh bar group (L7) is connected with the node member one (N4) through the fourth revolving pair (R44) of the node member one; The composition of the first rod group (L1) is represented as a simple serial kinematic chain -R11-R1-R41-, and the composition of the seventh rod group (L7) is represented as a simple serial kinematic chain -R44-R7-R51-.

[0019] The second branch includes the second revolving pair (R12) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com