Elevator steel wire rope tension automatic regulation system

An automatic adjustment, wire rope technology, applied in the field of elevators, can solve the problems that cannot be well guaranteed, the tension of each wire rope cannot be guaranteed, and the safety of passengers is affected. The effect of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

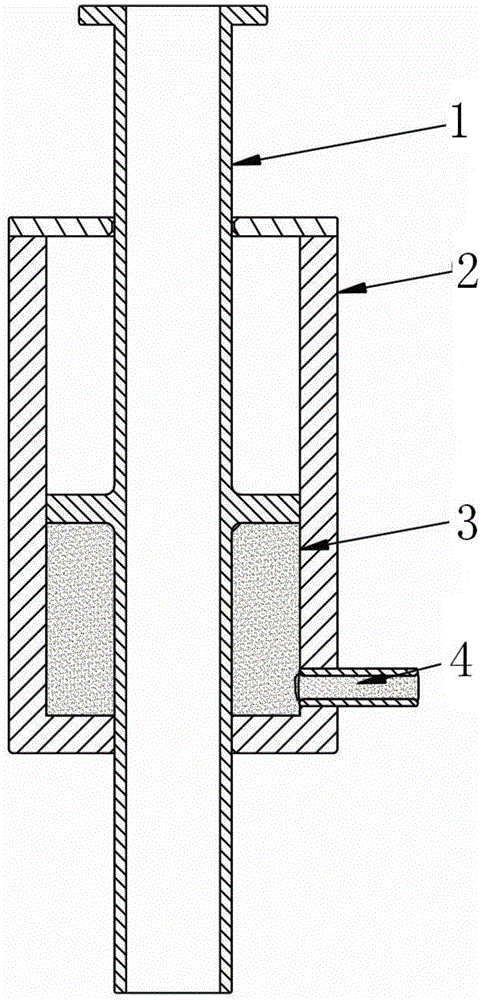

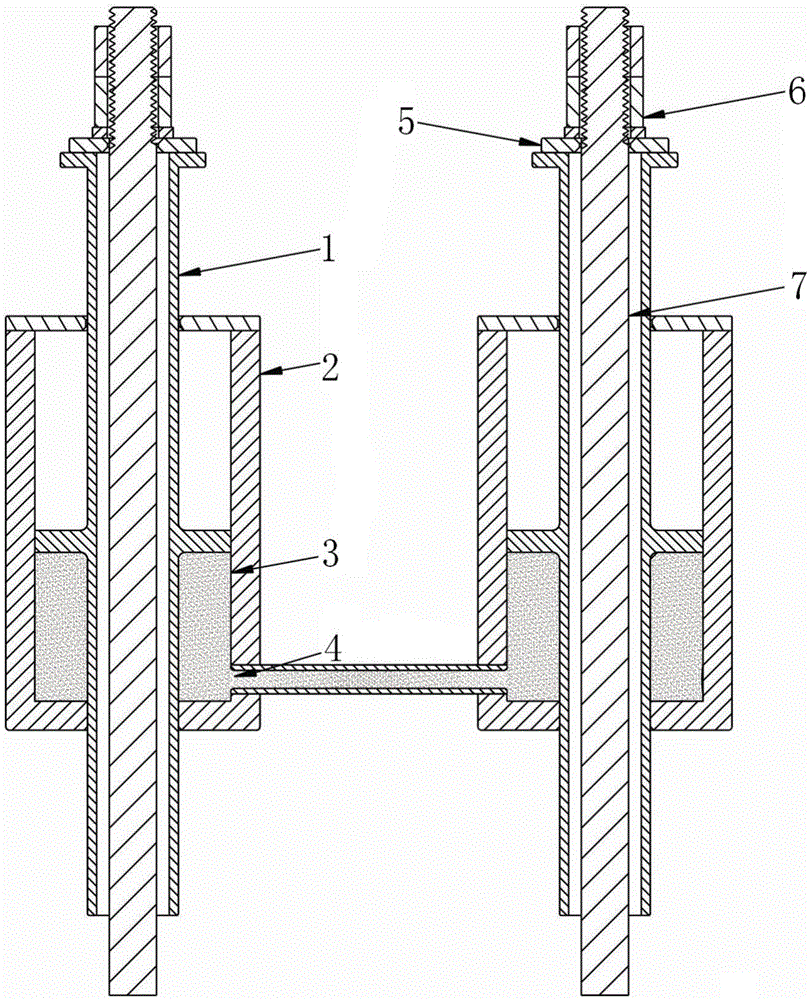

[0029] In this embodiment, the piston 1 includes a piston rod and a piston head, and the piston heads of all the pistons 1 have the same cross-sectional area. The piston head is located in the middle of the piston rod, the piston rod is a hollow structure and its two ends are respectively located outside the cylinder body 2, and the tail end pull rod 7 of the elevator wire rope is packed into the piston rod and fixedly connected with one end of the piston rod.

[0030] Such as figure 2 As shown, the tail end pull rod 7 of the elevator steel wire rope passes through the piston 1, and is fixed on the upper end of the piston 1 through the gasket 5 and the nut 6. The piston 1 is installed in the cylinder body 2, and the piston 1 and the cylinder body 2 form an inner cavity 3, and the inner cavity Water is housed in the cavity 3, and the tension force of the wire rope acts directly on the piston 1, and the piston 1 acts on the water in the cavity 3 again.

[0031] After the tail ...

Embodiment 2

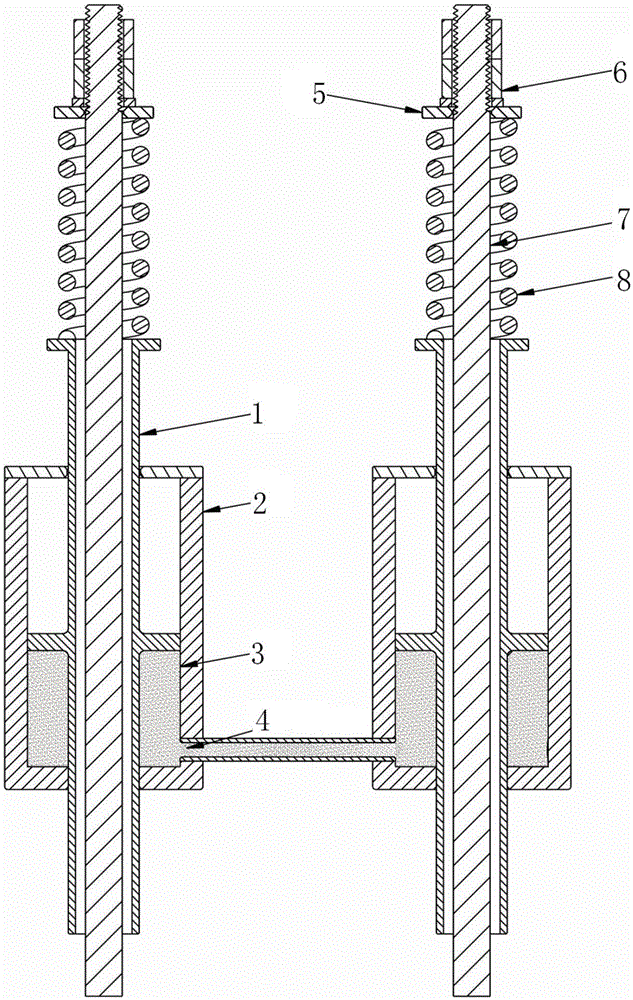

[0038] In this embodiment, the piston 1 includes a piston rod and a piston head, and the piston heads of all the pistons 1 have the same cross-sectional area. The piston head is located in the middle of the piston rod, the piston rod is a hollow structure and its two ends are respectively located outside the cylinder body 2, and the tail end pull rod 7 of the elevator wire rope is packed into the piston rod and fixedly connected with one end of the piston rod.

[0039] Such as image 3 As shown, the rope head spring assembly of the traditional wire rope is installed on the upper end of the piston 1, specifically, the tail end pull rod 7 of the elevator wire rope passes through the piston rod of the hollow structure of the piston 1, then passes through the damping spring 8, and passes through The washer 5 and the nut 6 are fixed on the upper end of the piston 1 , the lower end of the damping spring 8 is against the upper section of the piston rod, and the upper end of the dampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com