Biogas liquid and biogas residue solid-liquid separation method

A technology of solid-liquid separation and biogas residue, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of large vibration amplitude, easy blockage of filter screen, high residue content of biogas slurry, etc., and achieve strong adaptability of raw materials, The effect of good raw material adaptability and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

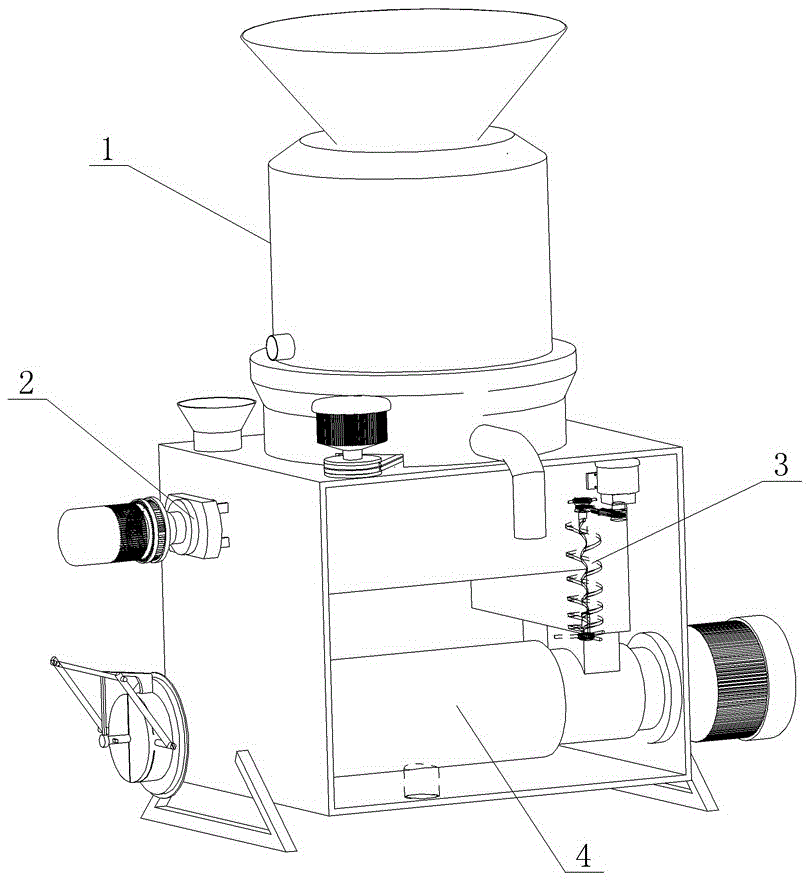

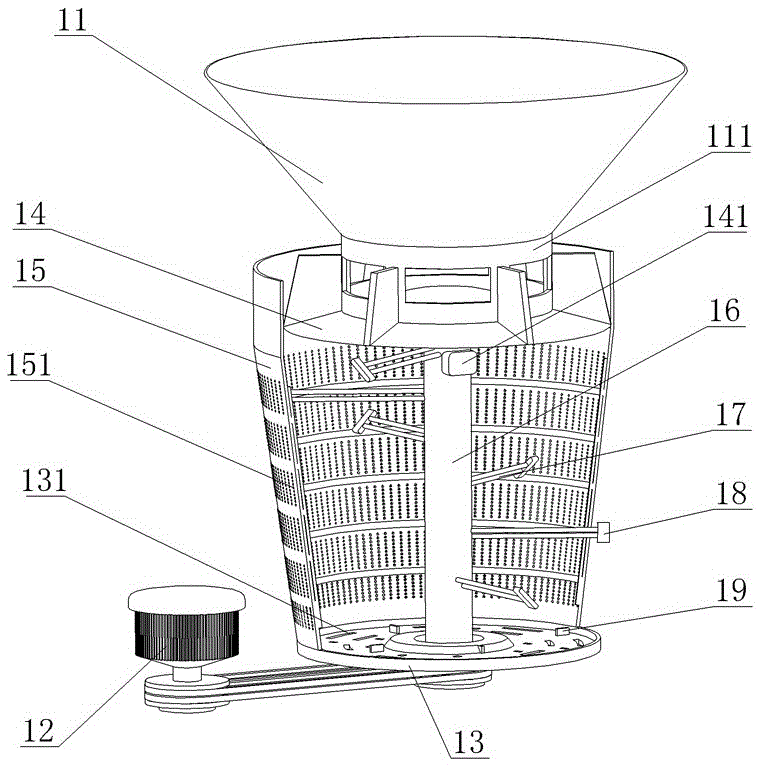

[0032] The method for solid-liquid separation of biogas slurry and residue in this embodiment adopts a centrifugal mechanism 1, an auxiliary stirring mechanism 2, a shaftless screw pressing mechanism 3, and a squeezing mechanism 4 that are connected to each other sequentially through pipe connections from front to back to separate the biogas slurry and residue. , the centrifugal mechanism 1 is provided with a feed hopper 11, and the auxiliary stirring mechanism 2 is provided with a secondary feed hopper, comprising the following steps:

[0033] 1) Put the biogas slurry and residue into the centrifugal mechanism 1 from the primary feeding hopper 11 to perform the first-stage centrifugal dehydration, discharge the separated biogas slurry, and transport the separated biogas residue to the auxiliary stirring mechanism 2;

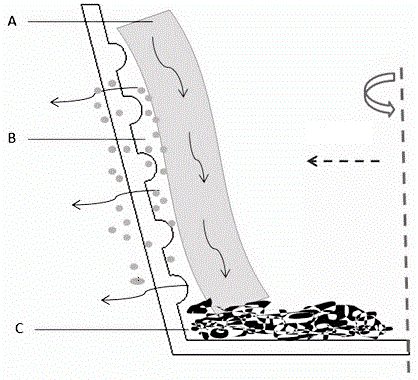

[0034] 2) Add rice husk or straw powder to the auxiliary mixing mechanism 2 through the secondary feeding hopper, and separate the biogas residue in the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com