A kind of production method of γ-chloropropyl trichlorosilane

A chloropropyltrichlorosilane, a production method technology, applied in chemical instruments and methods, compounds of periodic table Group 4/14 elements, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of poor selectivity and other problems, to achieve the effect of short reaction time, small amount of catalyst, and inhibition of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

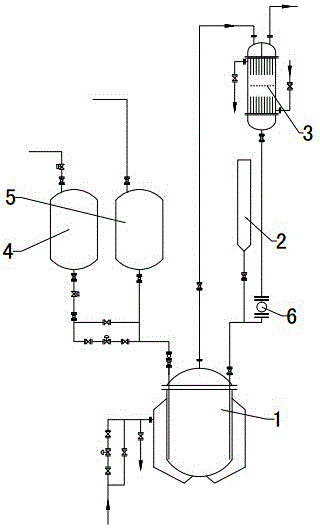

[0024] Before feeding, the 5m 3 Glass-lined reactor 1 is replaced once, and after completion, 1kg of 1% by mass chloroplatinic acid acetylacetone solution (385ppm of the total amount of trichlorosilane) is added from catalyst, additive and silicon tetrachloride inlet 2 , 7.8kg of 1,5-cyclooctadiene (3000ppm of the total amount of trichlorosilane) and 260kg of silicon tetrachloride (10% of the total amount of trichlorosilane), followed by 4 ingredients in the trichlorosilane metering tank 2600kg, 1475kg of chloropropene metering tank 5 ingredients. Put the material in the chloropropene metering tank 5 into the glass-lined reactor 1, and start adding trichlorosilane dropwise after confirming that it is correct. As the reaction progresses, the temperature of the glass-lined reactor 1 begins to rise gradually. When the temperature rises to 57°C At this time, silicon tetrachloride began to condense and reflux through the condenser 3, and there was reflux at the observation cup 6. ...

Embodiment 2

[0026] Before feeding, the 5m 3 The glass-lined reactor 1 is replaced once, and after completion, 0.9kg of 0.9% by mass chloroplatinic acid acetylacetone solution (350ppm of the total amount of trichlorosilane) is added from the catalyst, auxiliary agent and silicon tetrachloride inlet 2. ), 1,5-cyclooctadiene 7.8kg (3000ppm of the total amount of trichlorosilane) and 312kg of silicon tetrachloride (12% of the total amount of trichlorosilane), followed by 4 trichlorosilane metering tanks Batching 2600kg, chloropropene metering tank 5 batching 1560kg. Put the material in the chloropropene metering tank 5 into the glass-lined reactor 1, and start adding trichlorosilane dropwise after confirming that it is correct. As the reaction progresses, the temperature of the glass-lined reactor 1 begins to rise gradually. When the temperature rises to 57°C At this time, silicon tetrachloride began to condense and reflux through the condenser 3, and there was reflux at the observation cup ...

Embodiment 3

[0028] Before feeding, the 5m 3 Glass-lined reactor 1 is replaced once, and after completion, 1.08 kg of 1.3% by mass chloroplatinic acid acetylacetone solution (400 ppm of the total amount of trichlorosilane) is added from catalyst, auxiliary agent and silicon tetrachloride inlet 2. ), 7.28kg of 1,5-cyclooctadiene (2800ppm of the total amount of trichlorosilane) and 390kg of silicon tetrachloride (15% of the total amount of trichlorosilane), followed by 4 trichlorosilane metering tanks Batching 2600kg, chloropropene metering tank 5 batching 1690kg. Put the material in the chloropropene metering tank 5 into the glass-lined reactor 1, and start adding trichlorosilane dropwise after confirming that it is correct. As the reaction progresses, the temperature of the glass-lined reactor 1 begins to rise gradually. When the temperature rises to 57°C At this time, silicon tetrachloride began to condense and reflux through the condenser 3, and there was reflux at the observation cup 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com