A kind of high-strength wear-resistant PVC environmental protection tarpaulin film and preparation method thereof

A PVC resin powder and environmental protection technology, applied in the field of high-strength wear-resistant PVC environmental protection tarpaulin film and its preparation, can solve the problems of tear elongation, wear resistance, adverse effects on human body and environment, and environmental protection performance. , to achieve the effects of good plasticizing performance, enhanced wear resistance and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-strength wear-resistant PVC environmental protection tarpaulin film is prepared by the following steps:

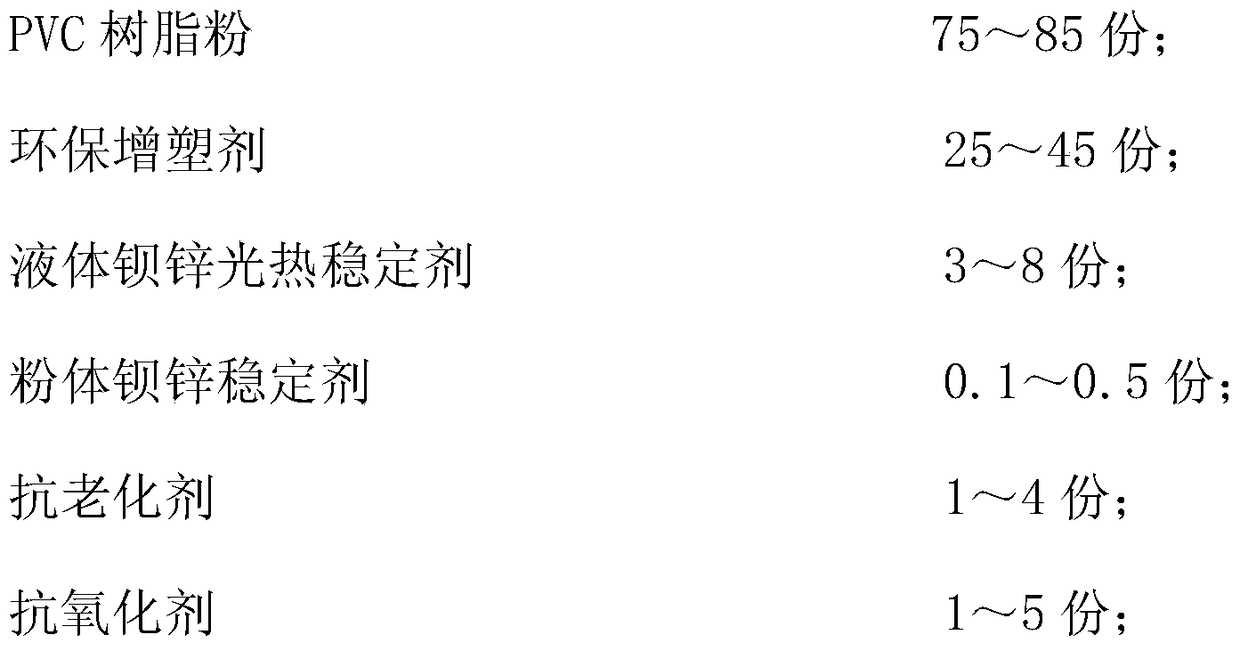

[0030] (1) Batching: each raw material is weighed according to the metering ratio; the weight ratio of the raw materials is:

[0031]

[0032] (2) Mixing and stirring: put the material into a high-speed mixer, first stir at a low speed for 60 seconds, then stir at a high speed, and then stir at a low speed to make the material form a uniform dispersion;

[0033] (3) Plastic refining: the uniform dispersion is automatically discharged into the 10,000-horsepower internal mixer through the pipeline, and further refined and plasticized into a mass under the pressure of the heavy hammer and the shear of the rotor;

[0034] (4) Opening: the mass is sent to the rolling mill (A), and the material is further rolled and plasticized under the relatively running rollers (the wheel gap is 8CM) to form a homogeneous phase, which is sent to the extrusion filter by the co...

Embodiment 2

[0039] A high-strength wear-resistant PVC environmental protection tarpaulin film is prepared by the following steps:

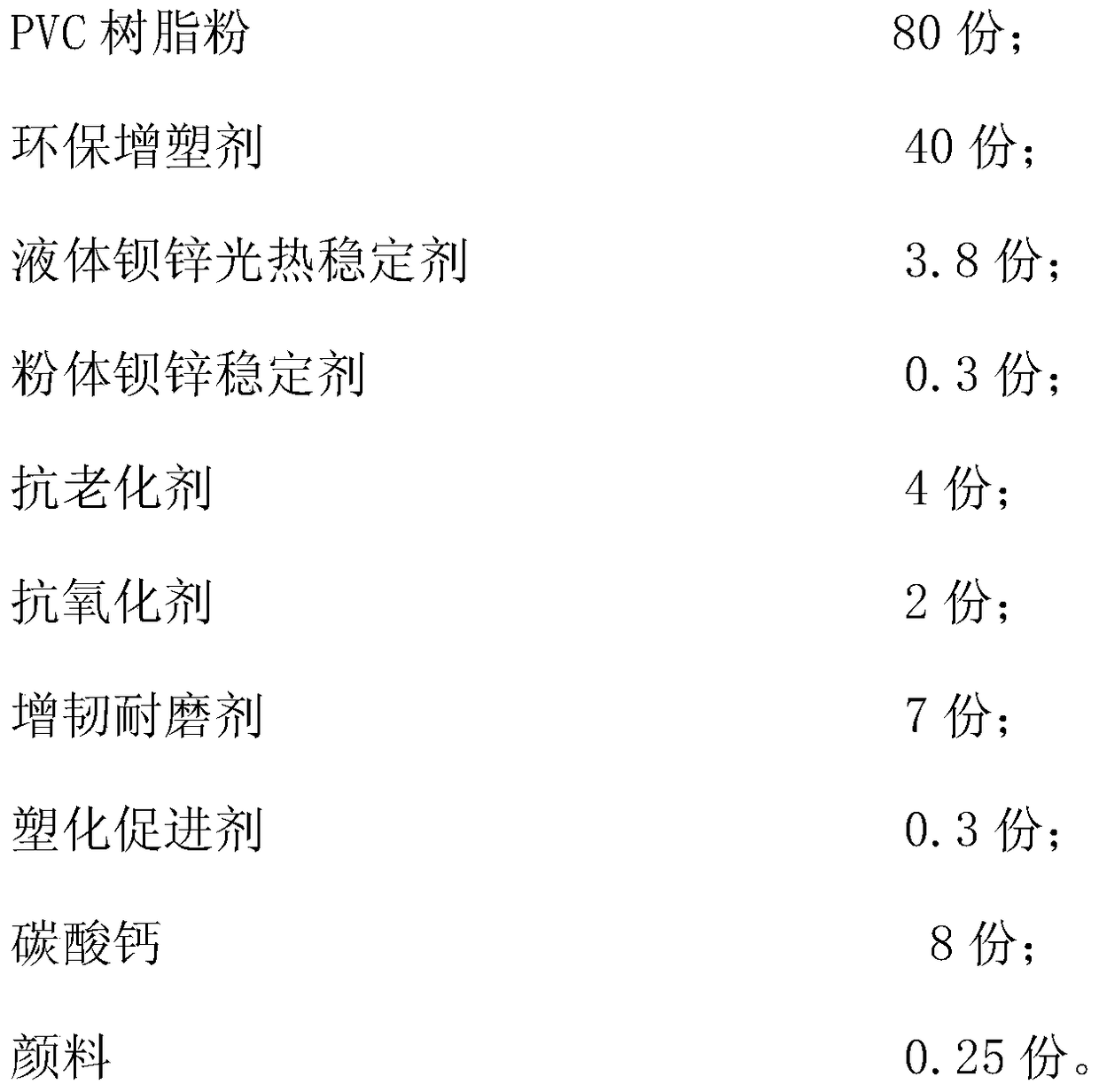

[0040] (1) Batching: each raw material is weighed according to the metering ratio; the weight ratio of the raw materials is:

[0041]

[0042] (2) Mixing and stirring: put the material into a high-speed mixer, first stir at a low speed for 60 seconds, then stir at a high speed, and then stir at a low speed to make the material form a uniform dispersion;

[0043] (3) Plastic refining: the uniform dispersion is automatically discharged into the 10,000-horsepower internal mixer through the pipeline, and further refined and plasticized into a mass under the pressure of the heavy hammer and the shear of the rotor;

[0044] (4) Opening: the mass is sent to the rolling mill (A), and the material is further rolled and plasticized under the relatively running rollers (the wheel gap is 8CM) to form a homogeneous phase, which is sent to the extrusion filter by the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com