Resource gradient cracking system

A cracking system and resource-based technology, which is used in the gasification of granular/powdered fuels, special forms of dry distillation, and the preparation of liquid hydrocarbon mixtures. problem, to achieve the effect of continuous cracking process and great promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Exemplary embodiments according to the present invention are described in detail below with reference to the accompanying drawings. Here, it should be noted that, in the drawings, the same reference numerals are assigned to substantially the same components in structure and function, and redundant descriptions about the substantially same components are omitted to make the description more concise.

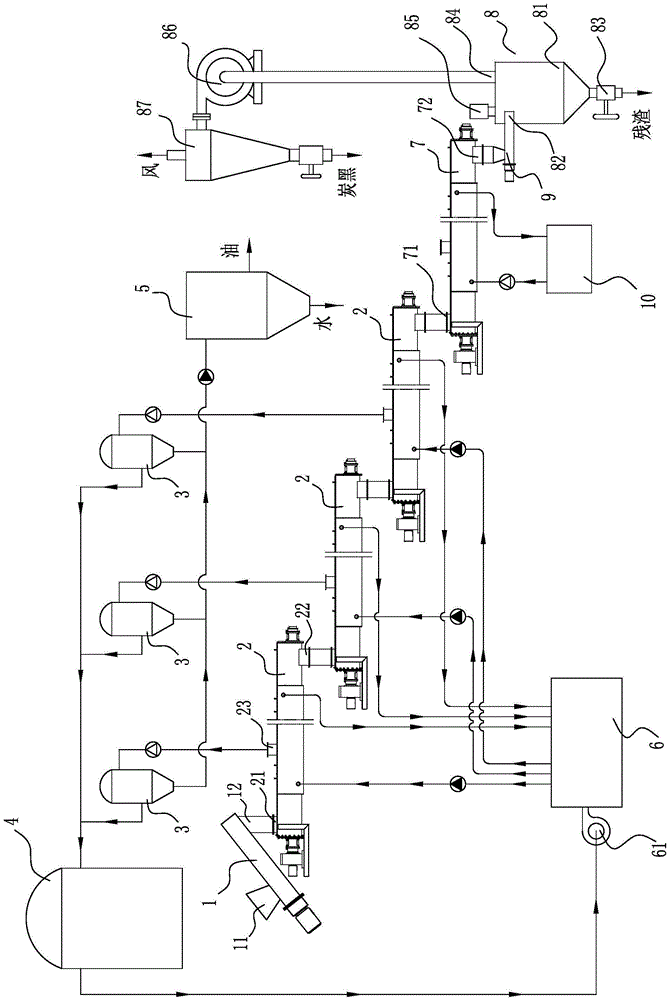

[0030] like figure 1 As shown, the recycling cascade cracking system includes:

[0031] see Figure 7 , the sealing feeding device is used to add the material that needs to be cracked without gas overflow, including the feeding device feeding hopper 11 and the feeding device discharging port 12;

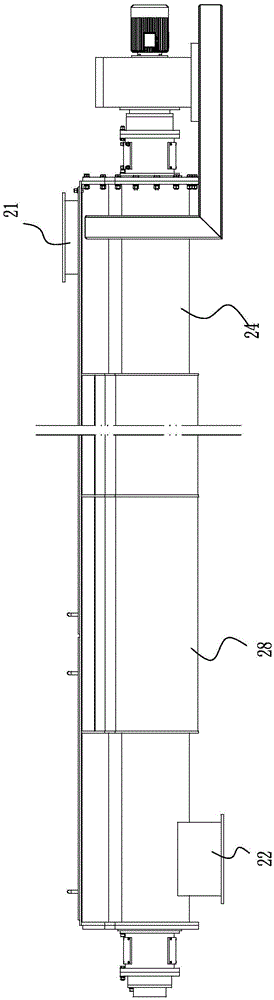

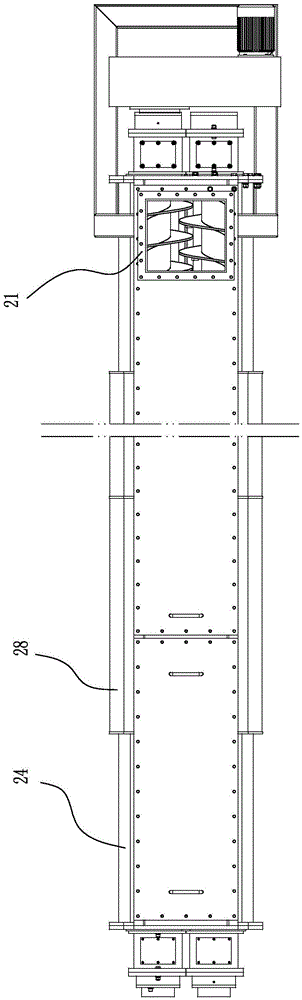

[0032] This embodiment adopts the double helix continuous cracking furnace 2 connected in three stages in series, wherein the first stage mainly plays the role of drying and preliminary cracking, the second stage mainly plays the role of cracking, and the third stage mainly play...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com