A method of using thermal plasma to heat treat organic waste gas

A thermal plasma, organic waste gas technology, applied in separation methods, gas treatment, combustion methods, etc., can solve the problems of high investment cost or use cost, high investment and use cost, low energy utilization efficiency, etc. The cost of consumables is reduced, the system runs stably and reliably, and the effect of meeting the needs of continuous and discontinuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

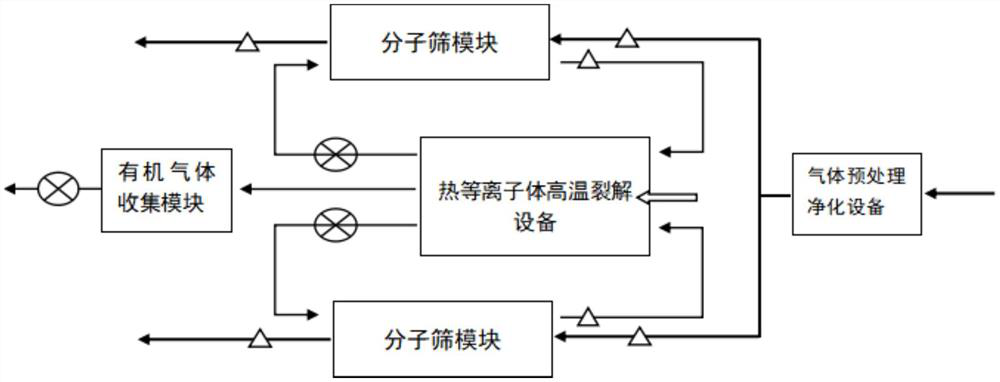

[0020] Such as figure 1 Shown, the present invention comprises the steps:

[0021] Because industrial organic waste gas usually contains a certain amount of dust particles, coupled with the long-term passage of industrial organic waste gas in the pipeline, due to the condensation of volatile matter, dust, etc. may adhere to the inner wall of the pipeline to form dirt, the dust in these industrial organic waste Dirt can easily lead to pipeline blockage and failure of downstream equipment, and even lead to hidden dangers of explosion. The entry of large particles of water droplets will affect the purification effect of the latter stage. Therefore, it is necessary to set up gas pretreatment and purification equipment to pretreat and purify industrial organic waste gas, effectively Effectively filter dust, oil, water mist and other particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com