A method for promoting the regeneration of reducing power and improving the conversion efficiency of microbial hydroxylated dhea

A DHEA and seed technology, applied in the biological field, can solve the problems of providing sufficient reducing power for the hydroxylation reaction, affecting the normal progress of the hydroxylation reaction, and NADPH consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

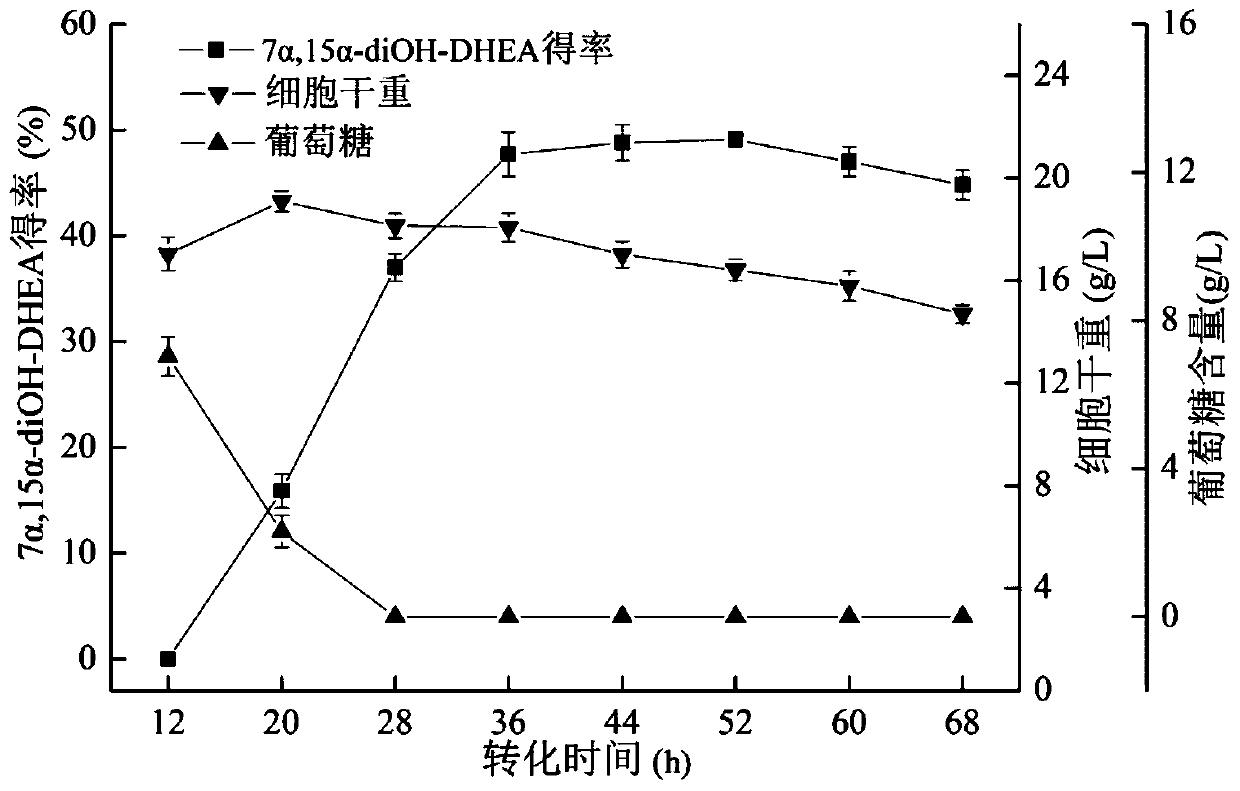

[0020] Research on the Hydroxylation of DHEA by Colletotrichum lini ST-1 under the Condition of High Substrate Feeding in Example 1

[0021] (1) Preparation of C.lini ST-1 cell liquid culture

[0022] C. lini ST-1 on the PDA solid medium was picked and inoculated into a 250mL Erlenmeyer flask filled with 30mL of fresh liquid seed medium, and cultured at 30°C and 120-220r / min for 24h. Then, the inoculation amount of 8-10% (v / v) is inserted into a 5L fermenter equipped with a fermentation medium, and the liquid filling amount is 3L. In the growth stage, the culture temperature is 25-40°C, the tank pressure is set to 0.05MPa, the rotation speed is set to 220-300r / min, the ventilation rate is 0.4-1.0vvm, and the dissolved oxygen level is maintained at 10-20%. After 12 hours of growth, That is, a liquid culture solution suitable for DHEA conversion is obtained;

[0023] (2) Hydroxylation of DHEA

[0024] Accurately weigh 15g / L powdered DHEA, and drop it into the bacterial cell c...

Embodiment 2

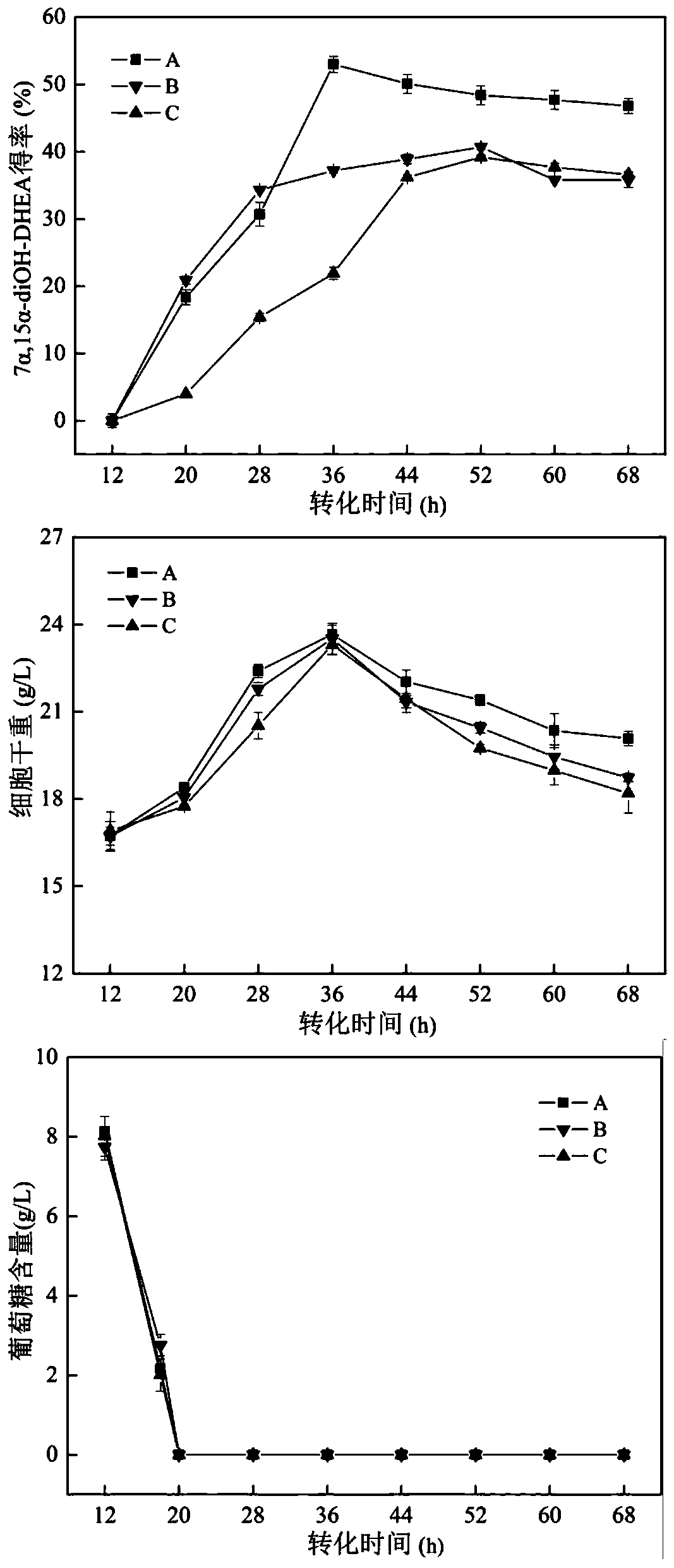

[0029] Example 2 Substrate Batch Adding Process to the Study of the Hydroxylation of DHEA

[0030] (1) Preparation of C.lini ST-1 cell liquid culture

[0031] C. lini ST-1 on the PDA solid medium was picked and inoculated into a 250mL Erlenmeyer flask filled with 30mL of fresh liquid seed medium, and cultured at 30°C and 120-220r / min for 24h. Then, the inoculation amount of 8-10% (v / v) is inserted into a 5L fermenter equipped with a fermentation medium, and the liquid filling amount is 3L. In the growth stage, the culture temperature is 25-40°C, the tank pressure is set to 0.05MPa, the rotation speed is set to 220-300r / min, the ventilation rate is 0.4-1.0vvm, and the dissolved oxygen level is maintained at 10-20%. After 12 hours of growth, That is, a liquid culture solution suitable for DHEA conversion is obtained;

[0032] (2) Substrate batch feeding process

[0033] The feeding method of three different substrates in batches is as follows: A) Accurately weigh three parts ...

Embodiment 3

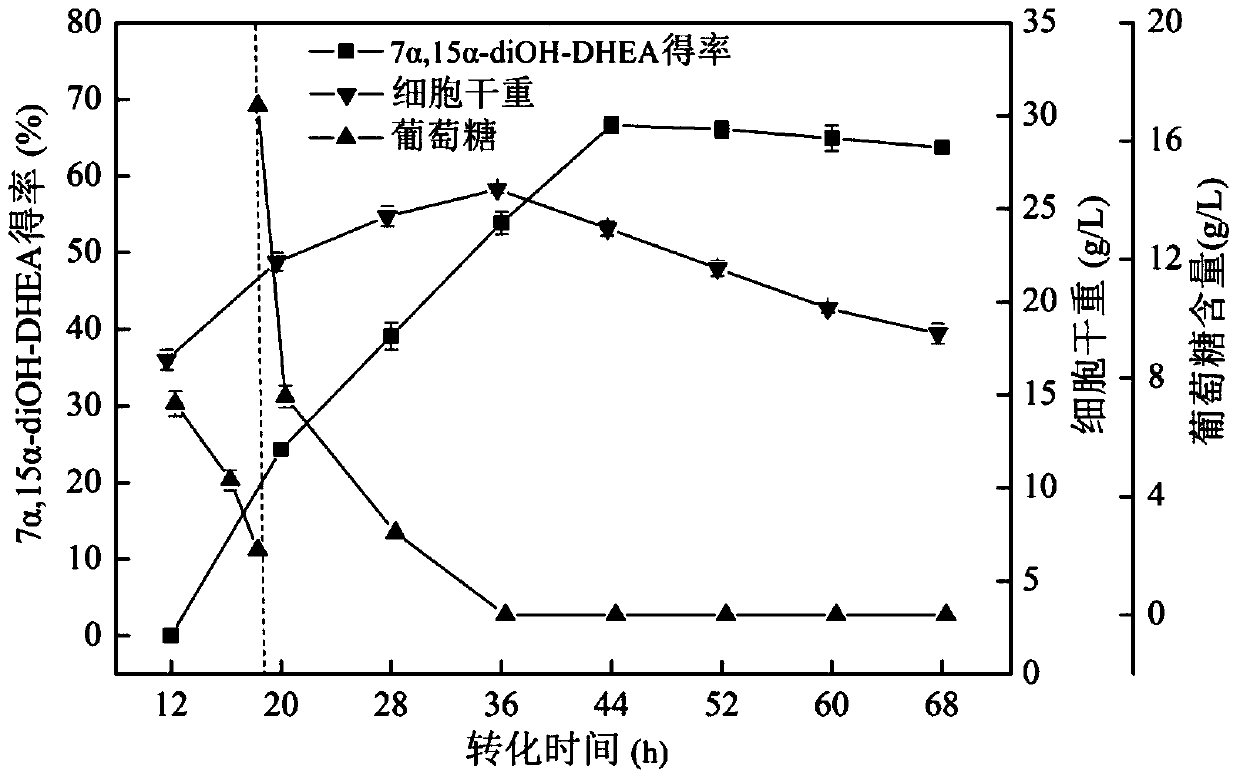

[0038] Example 3: Study on the Hydroxylation of DHEA by Combining Substrate Batch Feeding and Promoting Reducing Power Regeneration Process

[0039] (1) Preparation of C.lini ST-1 cell liquid culture

[0040] C. lini ST-1 on the PDA solid medium was picked and inoculated into a 250mL Erlenmeyer flask filled with 30mL of fresh liquid seed medium, and cultured at 30°C and 120-220r / min for 24h. Then, the inoculation amount of 8-10% (v / v) is inserted into a 5L fermenter equipped with a fermentation medium, and the liquid filling amount is 3L. In the growth stage, the culture temperature is 25-40°C, the tank pressure is set to 0.05MPa, the rotation speed is set to 220-300r / min, the ventilation rate is 0.4-1.0vvm, and the dissolved oxygen level is maintained at 10-20%. After 12 hours of growth, That is, a liquid culture solution suitable for DHEA conversion is obtained;

[0041] (2) Substrate batch dosing process

[0042] Accurately weigh three parts of 5g / L powdered DHEA, drop i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com