Deep cold rolling method for Invar steel belt

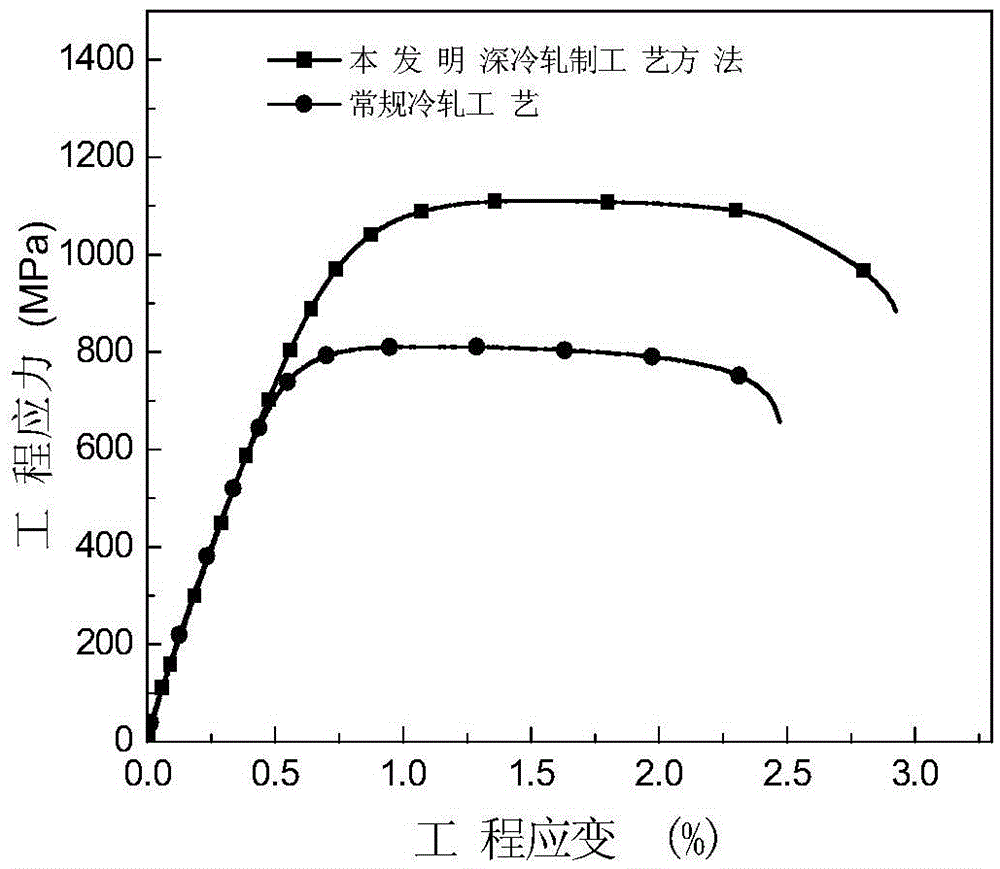

An invar steel and cryogenic technology, applied in the field of metallurgical materials, can solve the problem that the tensile strength value of invar steel cannot reach 900MPa, etc., and achieve the effects of low production cost, improved tensile strength, and abundant nitrogen resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

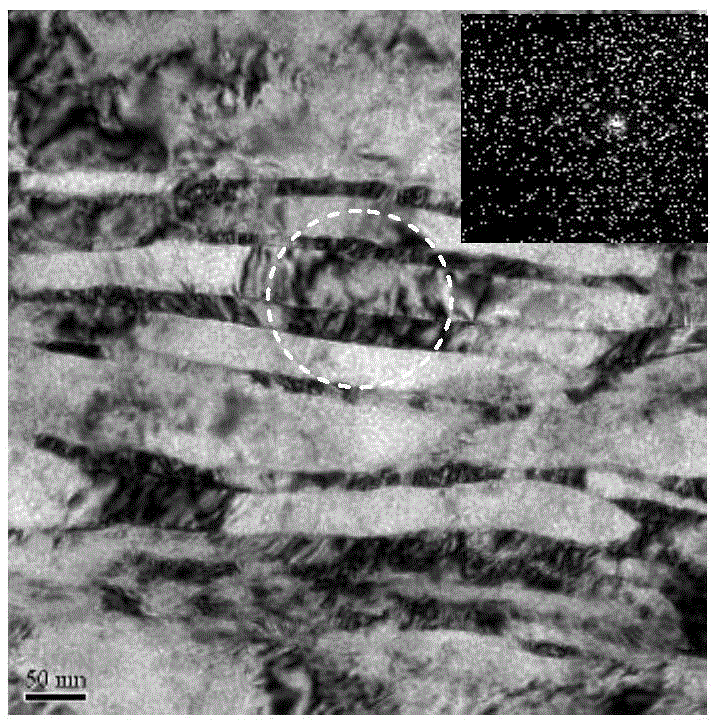

Image

Examples

Embodiment 1

[0028] The composition of Invar steel strip by mass percentage is: Ni: 35%, C: 0.01-0.1%, Mn: 0.01-0.05%, P<0.01%, S<0.01%, and the balance is Fe.

[0029] The cryogenic rolling method of Invar steel strip includes steps such as smelting, casting, hot rolling, solution treatment, and cryogenic rolling, as follows:

[0030] Step 1, smelting:

[0031] Put the raw materials into the vacuum according to the ratio of 0.5×10 -2 Pa high-frequency induction heating furnace, heated to 1500 ° C, after the raw material is melted into molten steel, smelted for 5 minutes, and inert gas is introduced;

[0032] Step 2, casting:

[0033] Cast the molten steel into the sand mold, demold and clean the surface of the ingot;

[0034] Step 3, hot rolling:

[0035] Heat the ingot to 1200°C, keep it warm for 3 hours, and place it on a hot rolling mill for blanking treatment. The initial rolling temperature is 1150°C, 7 passes of rolling, the total reduction rate is 90%, the final rolling tempera...

Embodiment 2

[0044] The composition of Invar steel strip by mass percentage is: Ni: 35.5%, C: 0.01-0.1%, Mn: 0.01-0.05%, P<0.01%, S<0.01%, and the balance is Fe.

[0045] The cryogenic rolling method of Invar steel strip includes steps such as smelting, casting, hot rolling, solution treatment, and cryogenic rolling, as follows:

[0046] Step 1, smelting:

[0047] Put the raw materials into the vacuum according to the ratio of 0.6×10 -2 Pa high-frequency induction heating furnace, heated to 1500 ° C, after the raw materials are melted into molten steel, smelted for 10 minutes, and inert gas is introduced;

[0048] Step 2, casting:

[0049] Cast the molten steel into the sand mold, demold and clean the surface of the ingot;

[0050] Step 3, hot rolling:

[0051] Heat the ingot to 1250°C, keep it warm for 2 hours, and place it on a hot rolling mill for blanking treatment. The initial rolling temperature is 1200°C, 7 passes of rolling, the total reduction rate is 90%, the final rolling te...

Embodiment 3

[0060] The composition of Invar steel strip by mass percentage is: Ni: 36%, C: 0.01-0.1%, Mn: 0.01-0.05%, P<0.01%, S<0.01%, and the balance is Fe.

[0061] The cryogenic rolling method of Invar steel strip includes steps such as smelting, casting, hot rolling, solution treatment, and cryogenic rolling, as follows:

[0062] Step 1, smelting:

[0063] Put the raw materials into the vacuum according to the ratio of 0.6×10 -2 Pa high-frequency induction heating furnace, heated to 1550 ° C, after the raw materials are melted into molten steel, smelted for 5 minutes, and inert gas is introduced;

[0064] Step 2, casting:

[0065] Cast the molten steel into the sand mold, demold and clean the surface of the ingot;

[0066] Step 3, hot rolling:

[0067] Heat the ingot to 1250°C, keep it warm for 2.5 hours, and place it on a hot rolling mill for blanking treatment. The initial rolling temperature is 1200°C, 7 passes of rolling, the total reduction rate is 90%, and the final rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com