Duplex stainless steel thin strip and near-net shaping preparation method thereof

A duplex stainless steel, near net forming technology, applied in the field of steel alloy materials, to achieve the effect of ensuring stability, eliminating pores and shrinkage defects, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

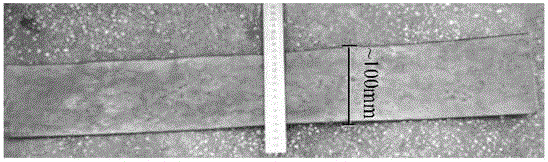

[0049] The composition of the duplex stainless steel thin strip of the present invention is: C = 0.018%; Cr = 18.9%; Ni = 0.052%; Mn = 6.3%; N = 0.38%; the balance is iron and other inevitable impurities.

[0050] A near-net-forming preparation method for a duplex stainless steel thin strip, specifically comprising the following steps:

[0051] Step 1, smelting:

[0052] Under the atmosphere of nitrogen, the pressure of the melting furnace is 1.0 atm. According to the composition ratio of the duplex stainless steel strip, the electrolytic chromium, electrolytic manganese and pure iron are first smelted at 1475 ° C, and then Fe (CrN) alloy is added after melting. The molten steel obtained by smelting is cast into a tundish, wherein the smelting is carried out under a nitrogen atmosphere, pressurized to suppress volatilization of manganese and nitrogen, and increase the yield of manganese and nitrogen;

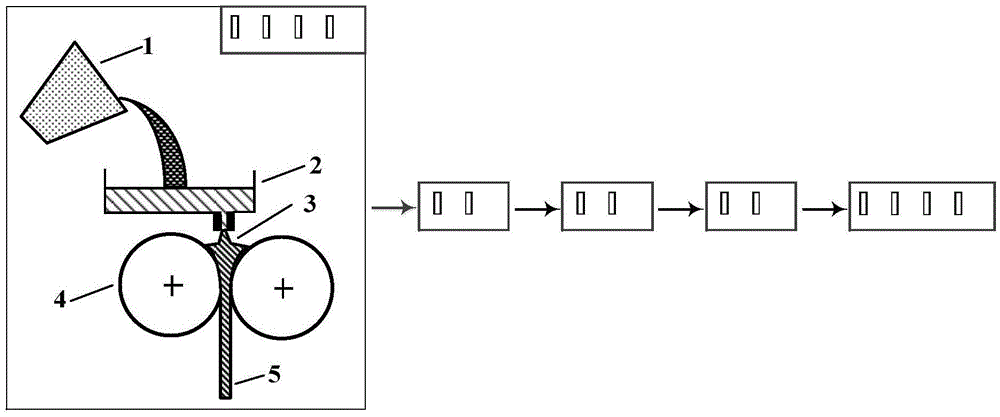

[0053] Step 2, thin strip continuous casting:

[0054] The molten steel i...

Embodiment 2

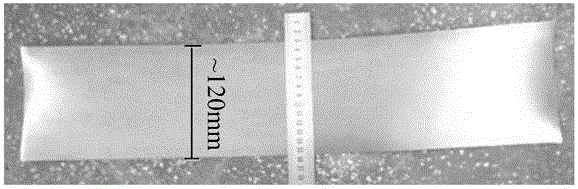

[0067] The composition of duplex stainless steel thin strip is: C=0.021%; Cr=19.6%; Ni=0.045%; Mn=5.6%; N=0.31%; the balance is iron and other unavoidable impurities.

[0068] A near-net-forming preparation method for a duplex stainless steel thin strip, specifically comprising the following steps:

[0069] Step 1, smelting:

[0070] Under a nitrogen atmosphere, the pressure of the melting furnace is 1.0 atm. According to the composition ratio of the duplex stainless steel strip, electrolytic chromium, electrolytic manganese and pure iron are first melted at 1500 ° C, and then Fe (CrN) alloy is added after melting. The molten steel obtained by smelting is cast into a tundish, wherein the smelting is carried out under a nitrogen atmosphere, pressurized to suppress volatilization of manganese and nitrogen, and increase the yield of manganese and nitrogen;

[0071] Step 2, thin strip continuous casting:

[0072] The molten steel in the tundish flows into the molten pool, and th...

Embodiment 3

[0085] The composition of duplex stainless steel thin strip is: C=0.014%; Cr=20.3%; Ni=0.032%; Mn=6.8%; N=0.45%; the balance is iron and other unavoidable impurities.

[0086] A near-net forming preparation method for a duplex stainless steel thin strip, specifically comprising the following steps:

[0087] Step 1, smelting:

[0088] Under nitrogen atmosphere, the pressure of the smelting furnace is 1.0atm. According to the composition ratio of the duplex stainless steel strip, electrolytic chromium, electrolytic manganese and pure iron are first smelted at 1470°C, and then Fe(CrN) alloy is added after melting. The molten steel obtained by smelting is cast into a tundish, wherein the smelting is carried out under a nitrogen atmosphere, pressurized to suppress volatilization of manganese and nitrogen, and increase the yield of manganese and nitrogen;

[0089] Step 2, thin strip continuous casting:

[0090] The molten steel in the tundish flows into the molten pool, and the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com