Anode carbon block structure for prebaking aluminum cell with no residue anode

An aluminum electrolytic cell and anode carbon block technology, applied in the field of anode carbon block structure, can solve the problems of anode residual electrode heat removal, heat waste, waste and other problems, and achieve the effects of reducing heat loss, saving heat energy, and stable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

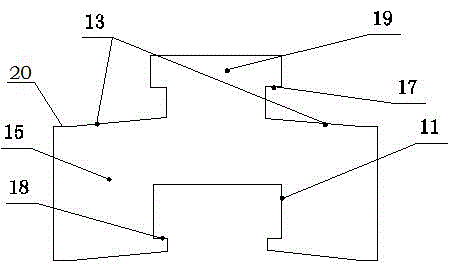

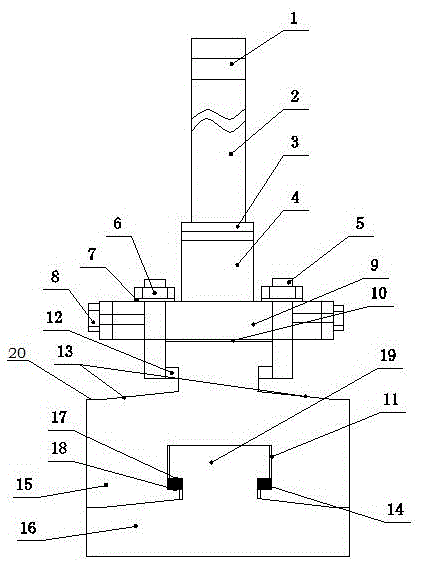

[0019] Embodiment: a kind of anode carbon block structure that does not produce residual electrode in prebaked aluminum electrolyzer, as attached figure 1 As shown, a carbon block body 15 is included, and the top of the carbon block body 15 is provided with a T-shaped connection protrusion 19 on the top of the carbon block, and a T-shaped connection protrusion bearing shoulder is provided on both sides of the T-shaped connection protrusion 19 on the top of the carbon block. 17. There is a T-shaped connection groove 11 at the bottom of the carbon block that is used in conjunction with the T-shaped connection protrusion 19 on the upper part of the carbon block. The bottom of the T-shaped connection groove 11 at the bottom of the carbon block is provided with a T-shaped connection groove hook bearing shoulder 18.

[0020] The tops on both sides of the carbon block body 15 are the upper surfaces 13 of the anode shoulders, and the upper surfaces 13 of the anode shoulders on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com