Industrial raw-cannabis-sativa-stem degumming method

A technology of industrial hemp and degumming method, applied in textile and papermaking, mechanical treatment, fiber mechanical separation, etc., can solve the problems of long degumming cycle, inconsistent degree of degumming, poor spinnability, etc. The effect of convenient humidity control and short degumming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

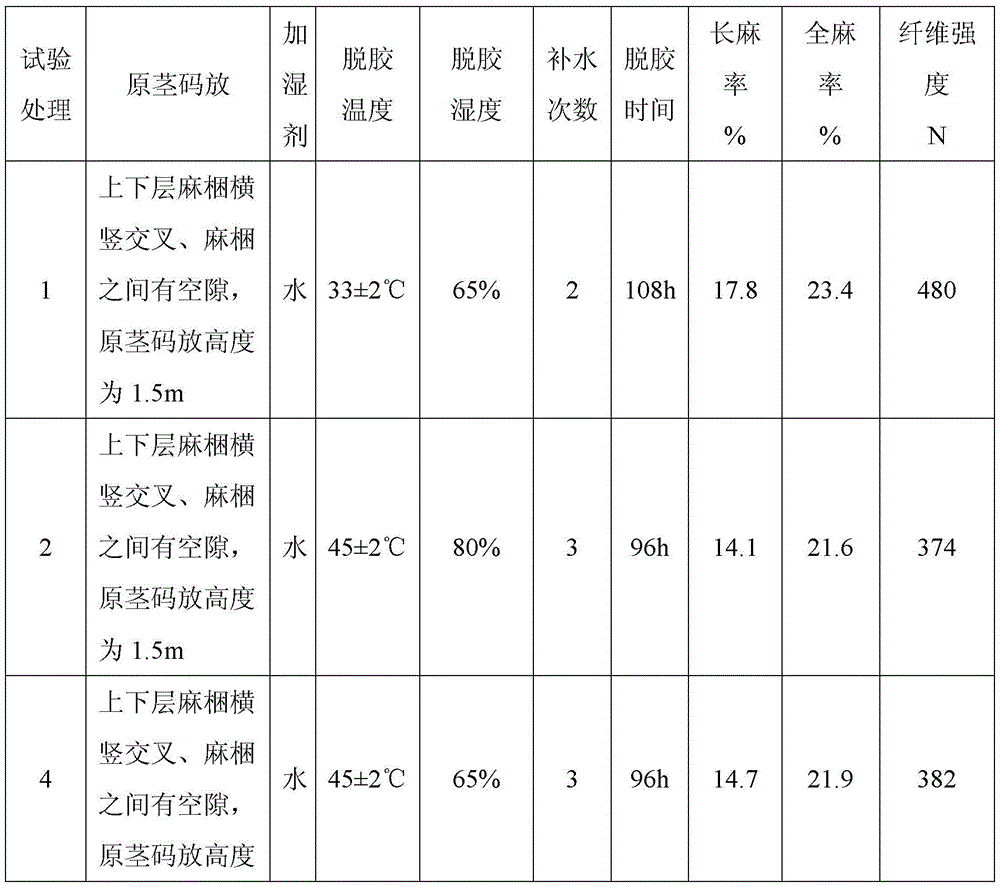

[0025] Specific embodiment one: in this embodiment, the original stem degumming method of industrial hemp is carried out through the following steps:

[0026] Step 1, bundling the dried hemp original stems into a 25cm-diameter bar to obtain the original stem bundles;

[0027] Step 2. Then use a criss-cross pattern to stack on flatbed trucks with a length of 5m and a width of 2m. The interval between two adjacent bundles on each layer is 25mm. Each truck is stacked with 20 bundles horizontally and 20 bundles vertically, with 6 layers of stacking, and then pulled to the plastic greenhouse. in the shed;

[0028] Step 3. Under natural light conditions, control the humidity in the plastic greenhouse at 65%, and control the temperature at 33±2°C. Under natural light conditions, when the sun is sufficient and the indoor temperature exceeds 35°C, it should be ventilated in time. Turn off the ventilation when it drops to about 25°C, and observe the degree of degumming at any time. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com