A kind of ordered nanofiber loaded with antitumor drug and its preparation method

An anti-tumor drug and nanofiber technology, applied in anti-tumor drugs, drug combination, fiber treatment and other directions, can solve the problems of uneven local drug distribution, drug burst release phenomenon, slow-release effect and other problems, and achieve drug-loaded concentration distribution. Uniform, good slow and controlled release effect, solving the effect of large local differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) In terms of parts by mass, 8 parts of dichloromethane and 2 parts of dimethylformamide are mixed to prepare a mixed solvent; the molecular weight is 8×10 4 Da polycaprolactone (PCL) and antineoplastic drug paclitaxel (purity ≥ 95%) are dissolved in this mixed solvent, wherein the amount of paclitaxel accounts for 1% of the total mass of paclitaxel and polycaprolactone, and polycaprolactone after dissolving The final concentration of lactone is 10%; stirring at 25°C for 12 hours, standing for degassing for 2 hours, to obtain an electrospinning solution;

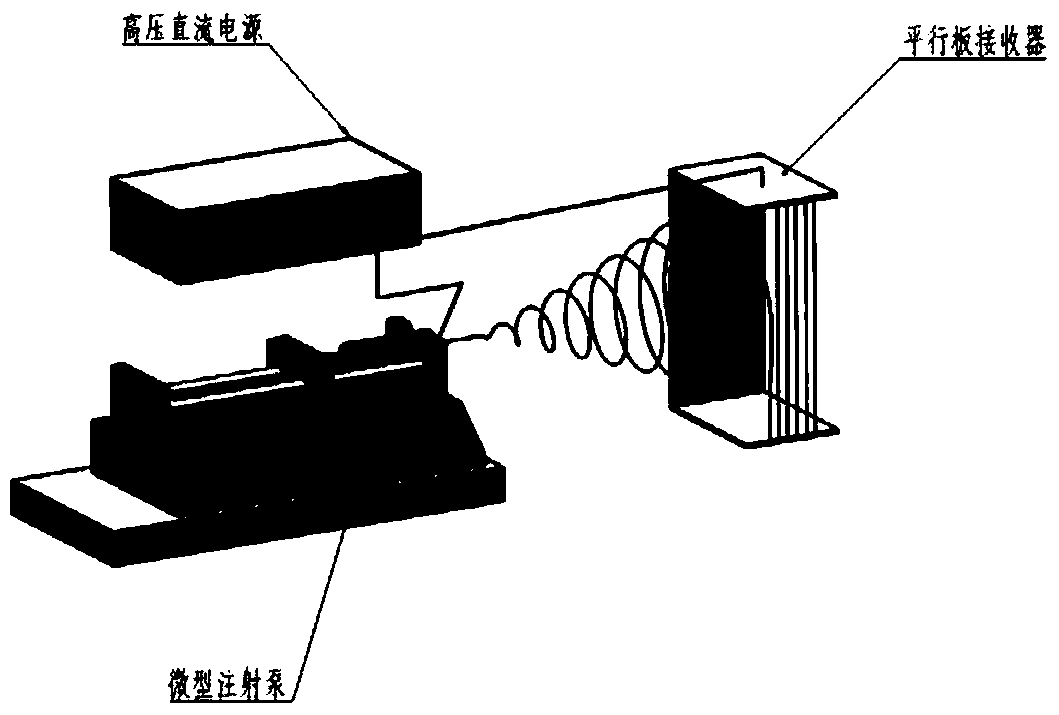

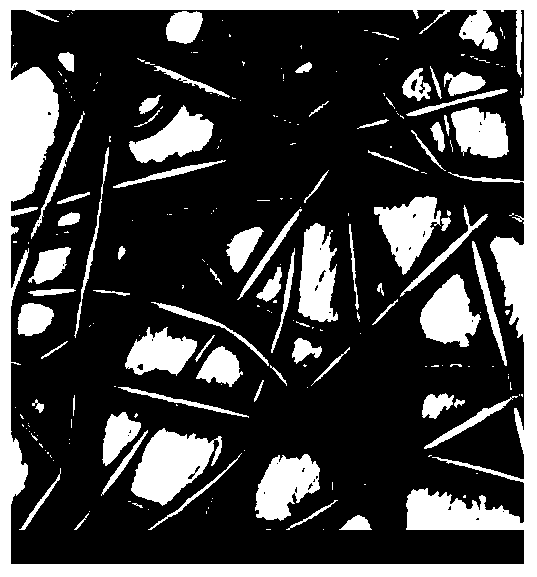

[0034] 2) Put the electrospinning solution in step 1) into a syringe at 25-35°C and a relative humidity of 40-70%, and perform electrospinning with a spinning voltage of 8kV and a spinning flow rate of 600μL / h; the receiver It is a parallel plate receiver arranged in parallel and spaced up and down, and the distance between the two plates is 10cm; the horizontal distance between the syringe needle, that is, the spinn...

Embodiment 2

[0037] 1) In terms of parts by mass, 8 parts of dichloromethane and 2 parts of dimethylformamide are mixed to prepare a mixed solvent; the molecular weight is 8×10 4 Da polycaprolactone and antineoplastic drug paclitaxel (purity ≥ 95%) are dissolved in this mixed solvent, wherein the amount of paclitaxel accounts for 2% of the total mass of paclitaxel and polycaprolactone, and the polycaprolactone after dissolving The final concentration is 10%, stirring at 25°C for 12 hours, standing for degassing for 2 hours, to obtain an electrospinning solution;

[0038] 2) Put the electrospinning solution in step 1) into a syringe at 25-35°C and a relative humidity of 40-70%, and perform electrospinning with a spinning voltage of 8kV and a spinning flow rate of 600μL / h; the receiver It is a parallel plate receiver arranged in parallel and spaced up and down, and the distance between the two plates is 10cm; the horizontal distance between the syringe needle, that is, the spinneret and the ...

Embodiment 3

[0041] 1) In terms of parts by mass, 8 parts of dichloromethane and 2 parts of dimethylformamide are mixed to prepare a mixed solvent; the molecular weight is 8×10 4 Da polycaprolactone and antineoplastic drug paclitaxel (purity ≥ 95%) are dissolved in this mixed solvent, wherein the amount of paclitaxel accounts for 3% of the total mass of paclitaxel and polycaprolactone, and the polycaprolactone after dissolving The final concentration is 10%, stirring at 25°C for 12 hours, standing for degassing for 2 hours, to obtain an electrospinning solution;

[0042]2) Put the electrospinning solution in step 1) into a syringe at 25-35°C and a relative humidity of 40-70%, and perform electrospinning with a spinning voltage of 8kV and a spinning flow rate of 600μL / h; the receiver It is a parallel plate receiver arranged in parallel and spaced up and down, and the distance between the two plates is 10cm; the horizontal distance between the syringe needle, that is, the spinneret and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com