Paper document deacidification device and method

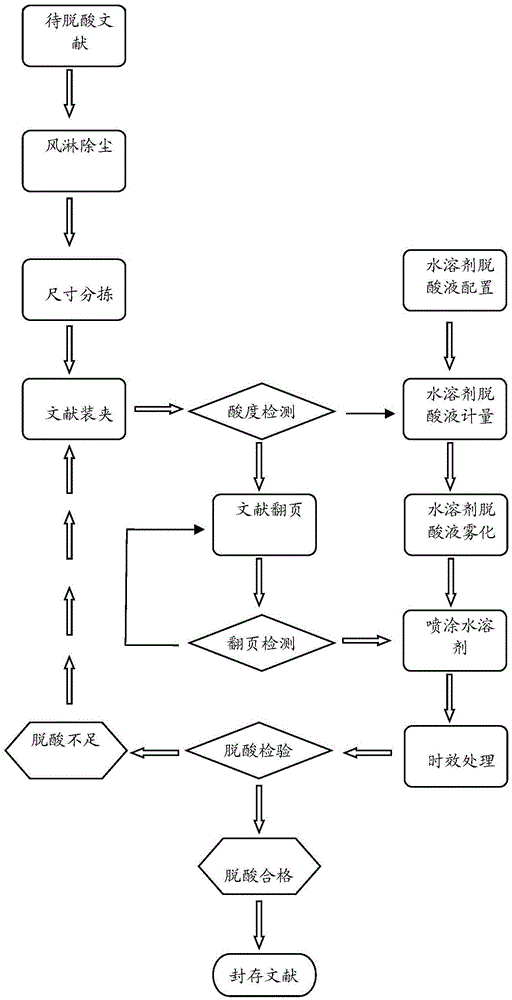

A document and deacidification technology, which is applied in the field of deacidification equipment for paper documents, can solve problems such as uneven deacidification, appearance deformation, flammability and explosion, etc., to solve uneven deacidification, improve operating efficiency, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the present invention, the paper document deacidification device and deacidification method provided by the present invention are described in detail below in conjunction with the examples, but they should not be understood as limiting the protection scope of the present invention.

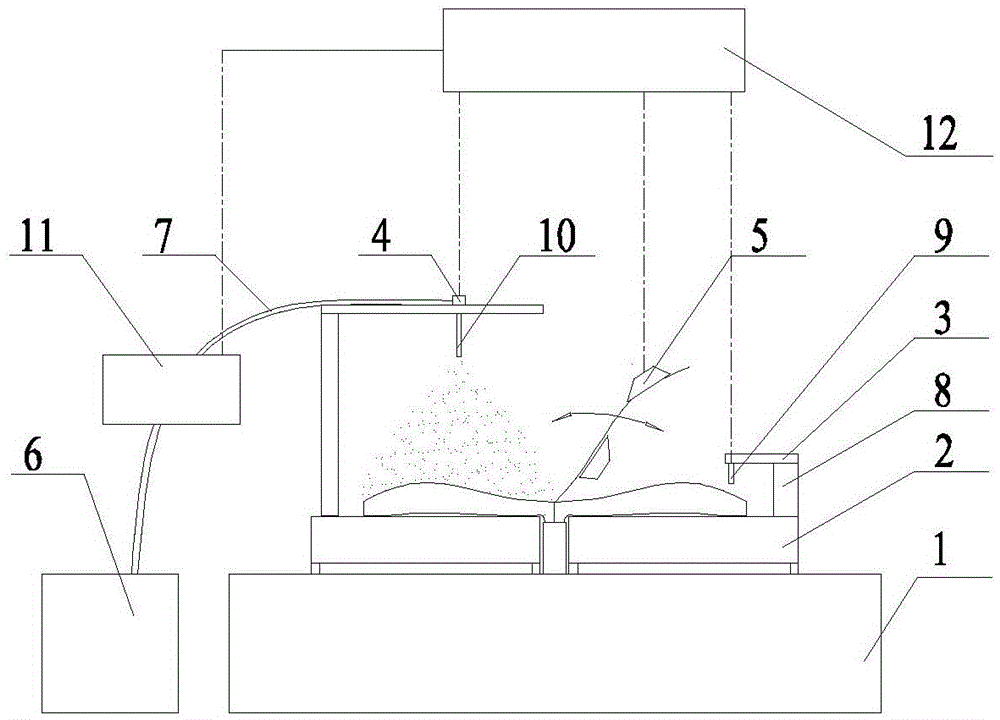

[0024] The embodiment of the present invention provides a paper document deacidification device, such as figure 1 As shown, it includes a controller 12, a base 1, a document bracket 2, a paper detection device 3, an atomization spraying device 4, a page turning device 5, a feed liquid pool 6, a water solvent deacidification liquid amount control device 11 and a water solvent deacidification liquid control device 11. The acid liquid delivery pipeline 7, the document bracket 2 is set on the base 1, the paper detection device 3 and the atomization spraying device 4 are set on the document bracket 2, and are respectively located on both sides of the document bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com