Method for dipulse preplating non-cyanide alkaline copper on ferro matrix

A double-pulse, pre-plating copper technology, which is applied in the field of electroplating copper, can solve the problems of low peak current density, high porosity of the coating, and delamination, and achieve the advantages of reducing concentration polarization, good bonding force of the coating, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

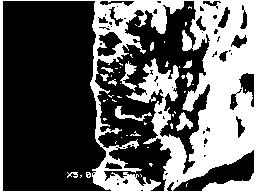

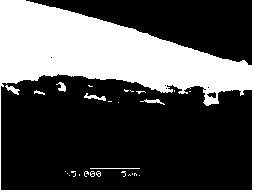

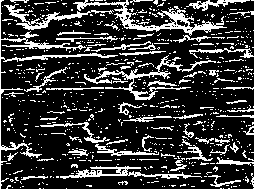

Image

Examples

Embodiment 1

[0028] (1) Prepare alkaline cyanide-free copper plating solution: firstly weigh 40g copper sulfate pentahydrate, 60g sodium citrate, 30g sodium sulfate decahydrate, and 2g potassium thiocyanate, and then weigh the copper sulfate pentahydrate, Sodium citrate, sodium sulfate decahydrate, and potassium thiocyanate are respectively dissolved in a small amount of distilled water or deionized water, and then mixed and stirred to obtain a mixed solution. Measure 50ml of alcoholamine and add to the mixed solution, weigh 6g of sodium hydroxide and use a small amount Dissolve in distilled water or deionized water, add to the mixed solution, dilute the mixed solution to 1 liter, mix well and set aside;

[0029] (2) Iron matrix pretreatment: First, degrease the iron matrix with a certain amount of degreaser at a temperature of 70~80℃. The degreaser used is 8g sodium hydroxide and 38g sodium carbonate per liter. , Sodium phosphate 50g, after the degreasing is completed, clean with hot water a...

Embodiment 2

[0034] The pulse process conditions in the double-pulse alkaline non-cyanide pre-plating copper are: the average forward current density is 0.4A / dm 2 , Reverse average current density 0.13A / dm 2 , The forward pulse width is 600μs, the reverse pulse width is 100μs, the forward cycle is 1000μs, and the reverse cycle is 3000μs. The other steps are the same as in Example 1.

Embodiment 3

[0036] The pulse process conditions in the double-pulse alkaline non-cyanide pre-plating copper are: the average forward current density is 0.8A / dm 2 ,Reverse average current density 0.26A / dm 2 , The forward pulse width is 600μs, the reverse pulse width is 100μs, the forward cycle is 1000μs, and the reverse cycle is 3000μs. The other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com