A kind of method for preparing 7α-methyl-19-aldehyde group-4-androstene-3,17-dione by electrocatalytic oxidation

A technology for electrocatalytic oxidation and androstene, which is applied in organic chemistry, electrolysis components, electrolysis processes, etc., can solve the problems of polluted environment, long reaction time, low product selectivity, etc., and achieves high product yield, low cost, selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

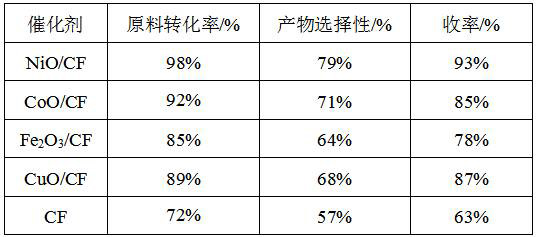

[0031] Example 1: Synthesis of NiO / CF Catalyst and its electrocatalytic oxidation 7α-methyl-17, 19-dihydroxy-4-α-methyl-19-aldehyde-4-4- Hernene-3,17-diketone

[0032](1) According to the press, 581 mg of nickel nitrate is dissolved in 80 mL distilled water, then 480 mg of urea and 296 mg of ammonium fluoride, and the solution is ultrasonically dispersed for 30 minutes to obtain a precursor solution A;

[0033] (2) Add the solution A and the carbon fabric in step 1) to the hydrothermal kettle, 12 hours in 120 ° C for 12 hours, then cool, remove the carbon cloth carrier, then washed three times with distilled water and ethanol, then placed The load type catalyst was dried in a vacuum drying tank at 60 ° C;

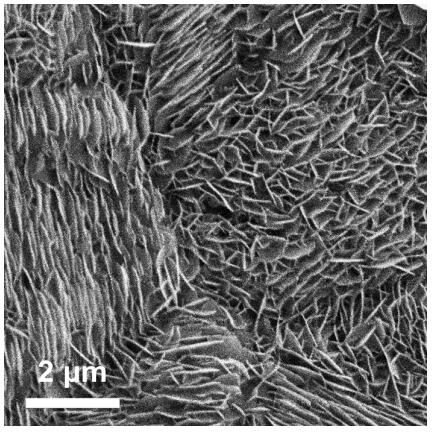

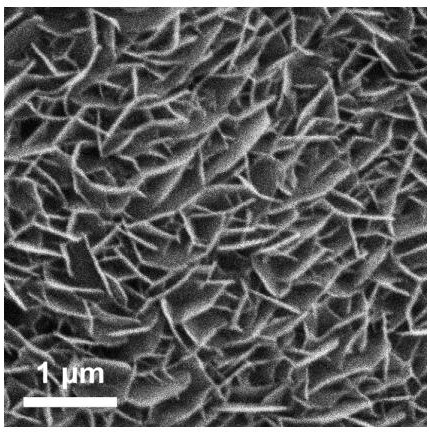

[0034] (3) Step 2) The dried load type catalyst is placed in a tube furnace, and 600 ° C is calcined at 600 ° C for 2 hours under the air atmosphere, i.e., obtaining the load type nickel oxide catalyst, labeled NIO / CF, SEM scanning electron microscopy figure 1 and 2 Indicat...

Embodiment 2

[0040] Example 2: Synthesis of COO / CF Catalyst and Its Electrocatalytic Oxidation 7α-Methyl-17, 19-Dihydroxy-4-Trobe-3-ketogenesis 7α-methyl-19-aldehyde-4- Hernene-3,17-diketone

[0041] (1) According to the press, 258 mg of cobalt chloride is dissolved in 40 mL distilled water, and then 240 mg of urea and 74 mg of ammonium fluoride, the solution is ultrasonically dispersed for 30 minutes to obtain a precursor solution A;

[0042] (2) Add the solution A and the carbon cloth in step 1 to the hydrothermal kettle, and the heat is 10 hours at 100 ° C, and the reaction is cooled, and the carbon cloth carrier is removed, then washed three times with distilled water and ethanol, then placed The load type catalyst was dried in a vacuum drying tank at 60 ° C;

[0043] (3) Step 2) The load-bearing catalyst was placed in a tubular furnace and calcined at 400 ° C under an air atmosphere for 2 hours, i.e., cooled to room temperature, i.e., to obtain a cobalt oxide catalyst, labeled COO / CF....

Embodiment 3

[0049] Example 3: Fe 2 O 3 Synthesis of cf catalyst and its electrocatalytic oxidation 7α-methyl-17, 19-dihydroxy-4-α-methyl-19-aldehyde-4-α-methyl-19-aldehyde-4-α -3-3 , 17-diketa

[0050] (1) According to the press, 726 mg of iron-soluble water was taken in 60 mL distilled water, and then 720 mg of urea and 222 mg of ammonium fluorinated ammonium fluoride, and the solution was ultrasonically dispersed for 30 minutes to obtain a precursor solution A;

[0051] (2) The solution A and the carbon cloth in step 1 are added to the hydrothermal kettle, and the hot reaction at 140 ° C for 6 hours, then cooled, then the carbon cloth carrier was removed, then washed three times with distilled water and ethanol, then placed The load type catalyst was dried in a vacuum drying tank at 60 ° C;

[0052] (3) Step 2) After drying the load type catalyst is placed in a tube furnace, calcined by 500 ° C for 1 hour under the air atmosphere, which is cooled to room temperature, i.e., obtaining the loa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com