A kind of reduced graphene oxide/polyurethane nanocomposite foam and its preparation method and application

A nanocomposite and graphene technology, which is applied in the field of nanocomposite material preparation, can solve the problems of insufficient stability of high thermal conductivity macroscopic assemblies, limited photothermal conversion efficiency of carbon-based materials, and difficulty in dispersing, achieving excellent chemical stability and excellent Reusable, efficient absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

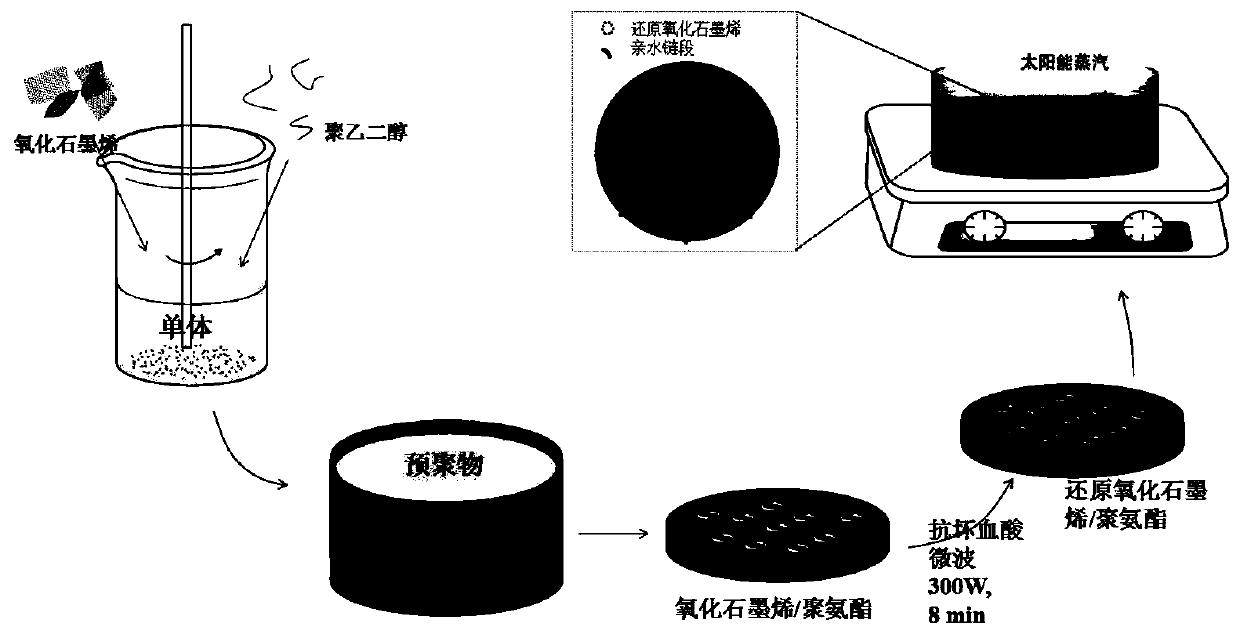

[0042] The invention provides a kind of preparation method of reduced graphene oxide / polyurethane nanocomposite foam, comprises the following steps:

[0043] (1) graphene oxide is mixed with an organic solvent to obtain a graphene oxide dispersion;

[0044] (2) The graphene oxide dispersion obtained in the step (1), polyether 330, polyethylene glycol, diisocyanate, triethanolamine, dibutyltin dilaurate, silicone oil and water are mixed to obtain a mixture, and the The mixture is prepolymerized to obtain a prepolymer;

[0045] (3) the prepolymer that described step (2) is obtained is foamed, obtains graphene oxide / polyurethane nanocomposite foam;

[0046] (4) Mix the graphene oxide / polyurethane nanocomposite foam obtained in the step (3) with a reducing agent, and perform reduction under microwave conditions to obtain reduced graphene oxide / polyurethane nanocomposite foam.

[0047] The invention mixes graphene oxide with an organic solvent to obtain a graphene oxide dispersio...

Embodiment 1

[0085] (1) Preparation of graphene oxide: Mix 360ml of concentrated sulfuric acid and 40ml of concentrated phosphoric acid and pour it into a three-necked flask equipped with 3g of flake graphite. Under the condition of magnetic stirring at 50°C, slowly add 18g of potassium permanganate and continue stirring 12 hours; then after the mixture is cooled to room temperature, pour it on about 400ml ice containing 3ml 30% hydrogen peroxide, continue to add hydrogen peroxide dropwise until it does not change color; then centrifuge the product to remove the supernatant, and the obtained product is washed , after ultrasonic stripping, flocculate with sodium hydroxide and dry at 20°C for 10 hours, and grind to obtain graphene oxide solid powder;

[0086](2) Preparation of graphene oxide / polyurethane nanocomposite foam: add 40 mg of graphene oxide obtained in step (1) to 4 ml of N,N-dimethylformamide, and ultrasonically disperse in an ultrasonic cleaner for 2 hours at room temperature to ...

Embodiment 2

[0099] According to the preparation method of Example 1, only the amount of polyether 330 was adjusted to 5.7 g, and the amount of polyethylene glycol 200 was adjusted to 1.9 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com