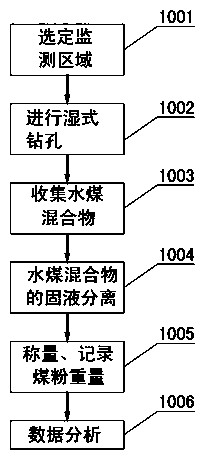

A wet cuttings method test system and test method for coal mine dynamic disasters

A technology for dynamic disasters and testing systems, applied in earth-moving drilling, wellbore/well components, flushing wellbore, etc., can solve the problems such as the inability to continue drilling cuttings method, drilling water, and wet pulverized coal, etc., to achieve the working principle Simple and reliable, easy to collect and weigh, to measure the effect of precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

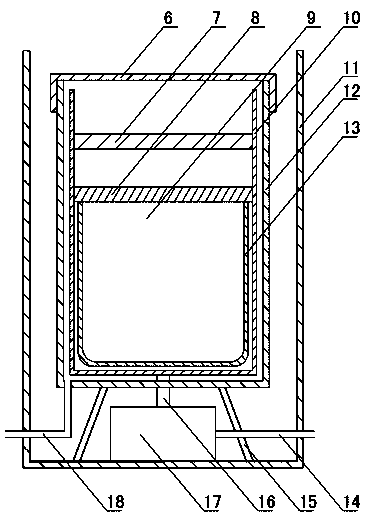

[0035] A wet drill cuttings testing system for coal mine dynamic disasters, including a drilling device for drilling pulverized coal, a collecting device for collecting pulverized coal, and solid-liquid separation for drying the pulverized coal drilled by the drilling device unit.

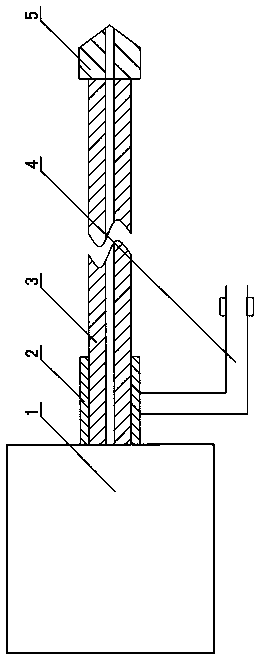

[0036] The drilling device in the wet drilling cuttings method test system for coal mine dynamic disaster is a water-passing drilling rig system, such as figure 1 As shown, the water-passing drilling rig system includes a drilling rig 1, a water-passing drill pipe 3 connected to the output end of the drilling rig 1, and a water-passing drill bit 5 installed at the end of the water-passing drill pipe 3. The water-passing drill pipe 3 and the drilling rig 1 are reliably connected by a connecting piece 2. A water inlet 4 is provided on one side of the connecting piece 2, and the water inlet 4 is connected with the water inlet channel arranged axially inside the water-passing drill pipe 3, and the water i...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that the rotating inner shell 10 is omitted from the rotating separation assembly and replaced by a rotating bracket. Such as Figure 4~5 As shown, the rotating support includes a bottom plate 20 and a plurality of arc-shaped vertical plates 19 vertically fixed on the upper surface of the bottom plate 20. The arc-shaped vertical plates 19 are uniformly fixed on the upper surface of the bottom plate 20. The top of the rotating shaft of the pneumatic device 17 is detachably connected to the bottom of the bottom plate 20, and the rotating bracket can be driven to rotate when the pneumatic device 17 rotates.

[0059] The upper opening of the filter cloth pocket 13 is placed on the bottom plate 20, the periphery of the pocket body is fixedly connected with the arc-shaped vertical plate 19, and the upper opening of the filter cloth pocket 13 is provided with a secondary filter screen 8 and a primary filter screen...

Embodiment 3

[0063] In this embodiment, the difference from embodiment 1 is that the rotating shafts of the rotating inner shell 10 and the pneumatic device 17 adopt a non-detachable design, and the rotation axis of the pneumatic device 17 passes through the water collecting shell 12 and then Rotating the bottom connection of the inner shell 10 drives it to rotate. Such as Image 6 As shown, the rotating inner shell 10 is provided with a net cover 21, the upper part of the net cover 21 is open, the net cover 21 and the rotating inner shell 10 are connected and fixed by a detachable fixing member 22, and the pneumatic device 17 is driving the rotating inner shell 10. When rotating, the mesh cover 21 is driven to rotate at the same time, and the fixing member 22 can be realized in a variety of detachable ways, such as a plug-in type.

[0064] A filter cloth pocket 13 is placed inside the net cover 21, the upper end of the filter cloth pocket 13 is open, and the pocket body is attached to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com