Urea formaldehyde drying method

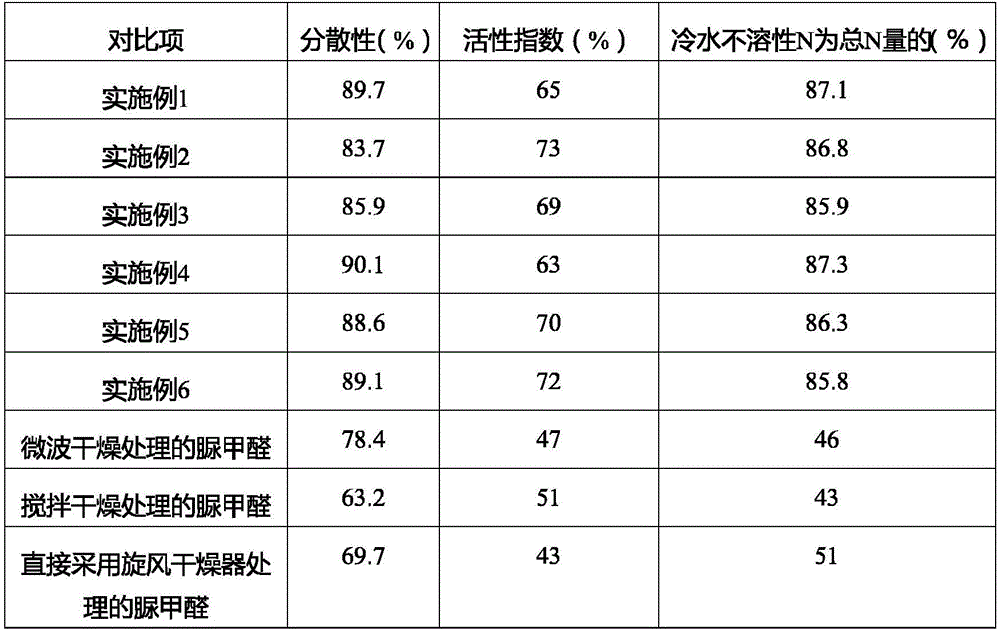

A drying method, urea-formaldehyde technology, applied in the direction of drying solid materials, heating to dry solid materials, promoting the preliminary treatment of solid materials drying, etc., can solve the problems of long drying time, easy agglomeration and hardening of urea-formaldehyde, property damage, etc. , to achieve the effect of reducing the probability of agglomeration, high activity and dispersibility, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

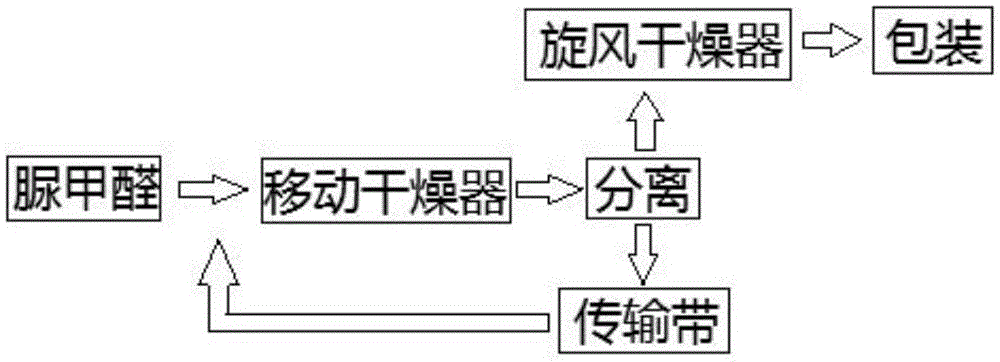

Embodiment 1

[0028] Select urea-formaldehyde with a moisture content of 40%, and spread it naturally on the conveyor belt of the mobile dryer. The thickness of the tile is 1cm. 30°C, the length of the mobile dryer is 3m, and the moving speed of urea-formaldehyde in the mobile dryer is 3m / h; a cyclone dryer is installed at the outlet of the mobile dryer, and the entrance of the cyclone dryer is connected with the mobile dryer. The distance from the outlet of the dryer is 2cm, adjust the temperature in the cyclone dryer to 70°C, and the wind speed to 17m / s, so that the 0.5mm thick layer of urea formaldehyde coming out of the mobile dryer is sucked into the cyclone dryer from top to bottom , so that the moisture content after coming out of the cyclone dryer is 0.5%, it can be packaged.

Embodiment 2

[0030] Select urea-formaldehyde with a moisture content of 50%, and lay it naturally on the conveyor belt of the mobile dryer. The thickness of the tile is 2cm. The temperature is higher than 20°C, the length of the mobile dryer is 11m, and the moving speed of urea-formaldehyde in the mobile dryer is 5m / h; a cyclone dryer is installed at the outlet of the mobile dryer, and the inlet of the cyclone dryer is connected to the The distance from the outlet of the mobile dryer is 4cm, adjust the temperature in the cyclone dryer to 80°C, and the wind speed to 20m / s, so that the urea-formaldehyde coming out of the mobile dryer is sucked into the cyclone from top to bottom with a thickness of 2mm In the desiccator, make the moisture content after coming out from the cyclone drier be 1%, can pack.

Embodiment 3

[0032] Select urea-formaldehyde with a moisture content of 45%, and lay it naturally on the conveyor belt of the mobile dryer. The thickness of the tile is 1.5cm. The temperature is higher than 10°C, the length of the mobile dryer is 8m, and the moving speed of urea-formaldehyde in the mobile dryer is 4m / h; a cyclone dryer is installed at the outlet of the mobile dryer, and the entrance of the cyclone dryer is connected to the The distance between the outlet of the mobile dryer is 3cm, adjust the temperature in the cyclone dryer to 75°C, and the wind speed to 18m / s, so that the urea-formaldehyde coming out of the mobile dryer is sucked from top to bottom in a 1.5mm thick layer In the cyclone drier, make the moisture content after coming out from the cyclone drier be 0.8%, can pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com