An online detecting method for metal wire surface detects and a detecting device

A metal wire and detection method technology, applied in the direction of material magnetic variables, etc., can solve the problems of low inspection efficiency, waste of batches, poor reliability, etc., and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

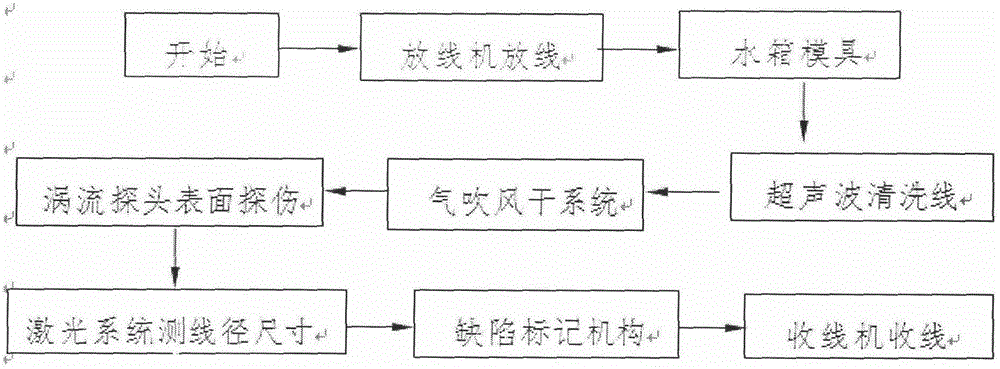

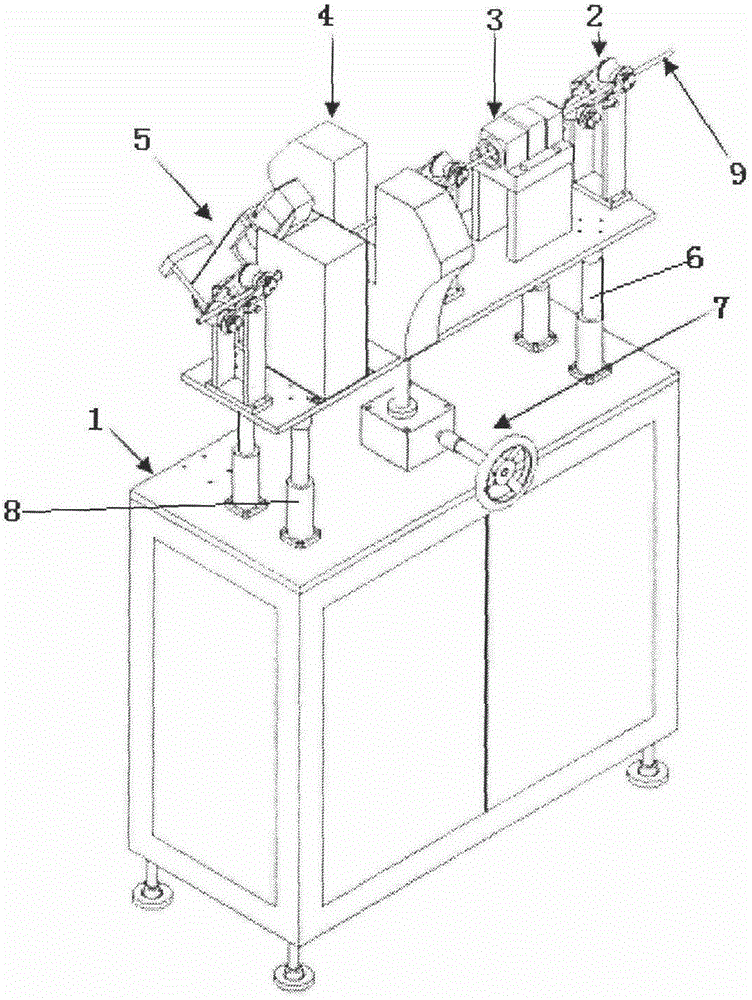

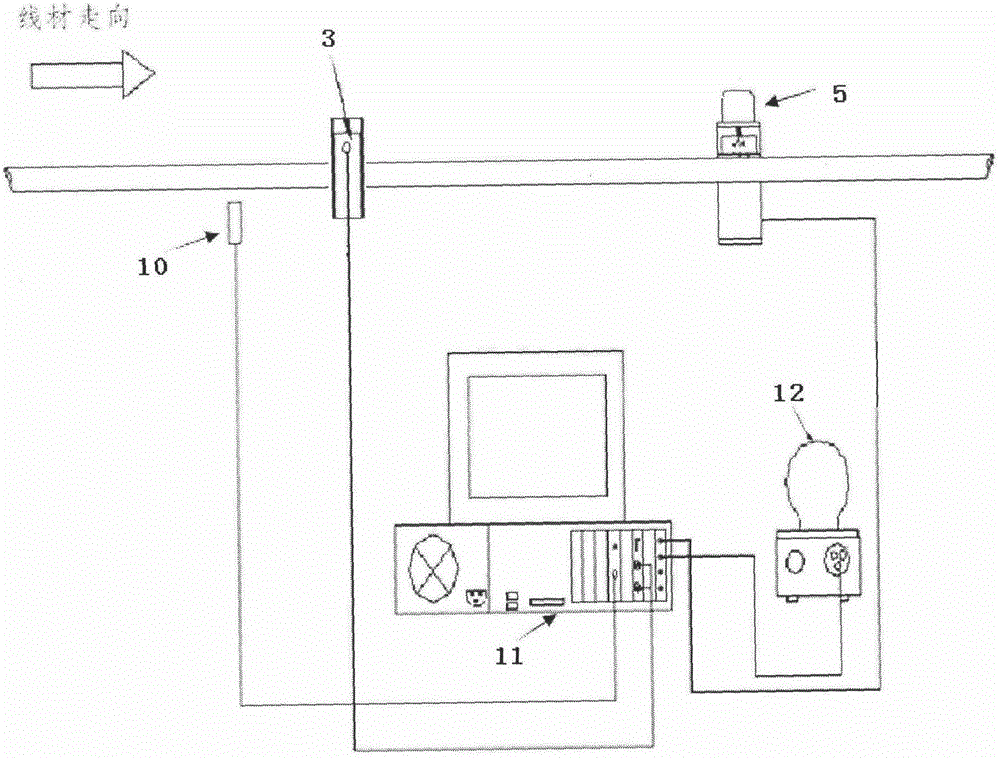

[0036] Take the online monitoring process of aluminum alloy wire ER5356 with a diameter of φ2.17 as an example. After the system starts running, the pay-off machine can pay off the wire at a constant speed between V=4m / s; then enter the water tank and use a φ2.028 ordinary polycrystalline mold drawing die to stretch and deform the wire, from a diameter of φ2. 17 is drawn to φ2.0; the drawn wire enters the ultrasonic cleaning device to remove surface oil stains, the ultrasonic vibration plate is 3kw, the water temperature is controlled at 58°C, and the clean water is freshly replaced in the morning; the cleaned wire enters the air drying system to remove moisture , the wind pressure is kept at 32Kpa, and the temperature inside the air gun is at 73°C; after air drying, the clean and dry wire enters the eddy current probe, and the eddy current probe detects the wire at a frequency of 32Khz; then enters the laser system to measure the wire diameter, and the wire diameter is display...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com