Optimal control method and control system for aeration and push flow process in oxidation ditch

An optimization control and oxidation ditch technology, applied in general control system, control/regulation system, self-adaptive control, etc., can solve the difficulty of coordinated adjustment of aeration and push flow equipment, and the differences in equipment adjustment methods are very different. Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

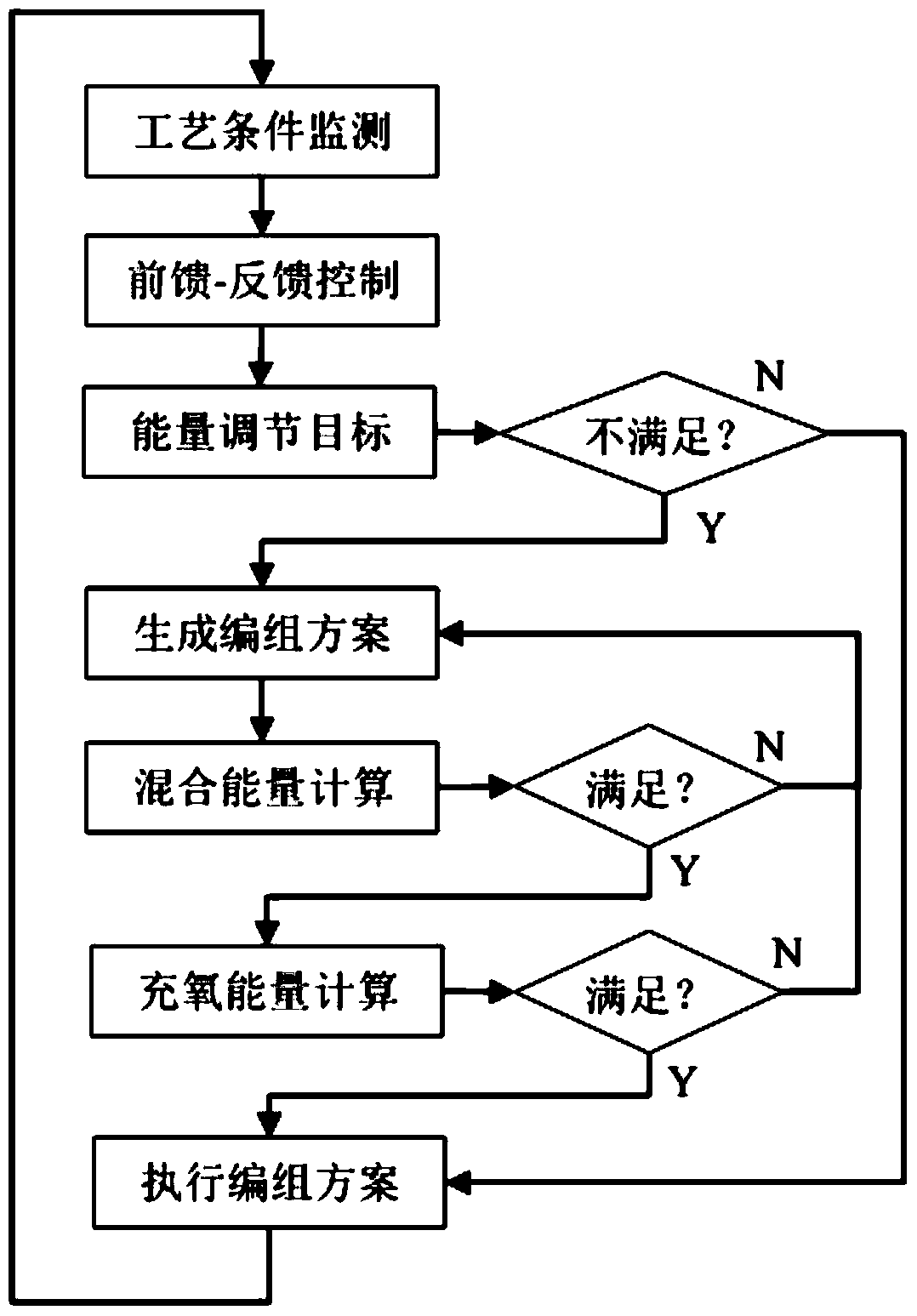

Method used

Image

Examples

Embodiment 1

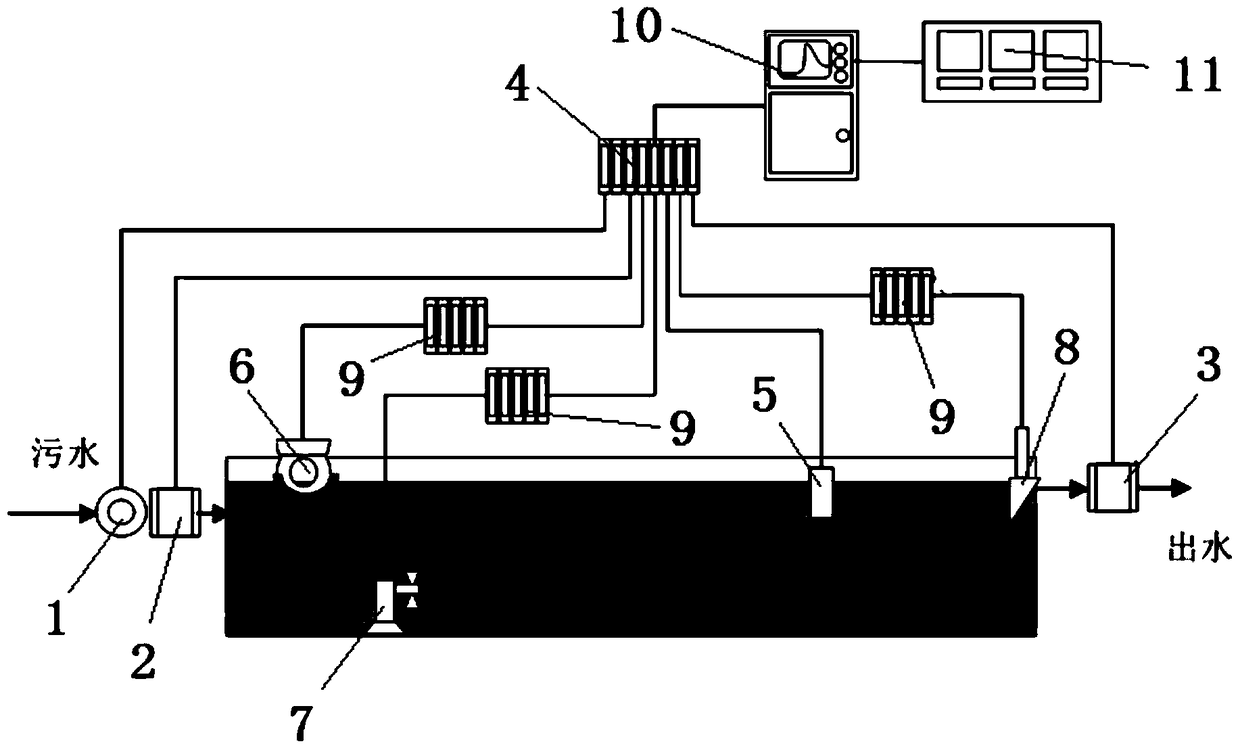

[0130] Example 1: Aeration and push flow control of rotating disc in an oxidation ditch process

[0131] Process operation status: Orbal oxidation ditch process with a scale of 50,000 tons / day. The layout of the instruments is as follows: an online ammonia nitrogen meter (ion selective electrode method) and an electromagnetic flowmeter are arranged up to the front of the water inlet of the ditch outside the process to measure the concentration of ammonia nitrogen in the influent C IN and flow Q IN; An online sludge concentration meter (optical method) was arranged inside the biological reaction tank of the outer ditch, and was immersed 0.5 meters below the page to measure the sludge concentration MLSS; an online ammonia nitrogen meter (ion selective electrode method) was arranged at the outlet of the secondary sedimentation tank to measure Effluent ammonia nitrogen concentration C EN wait.

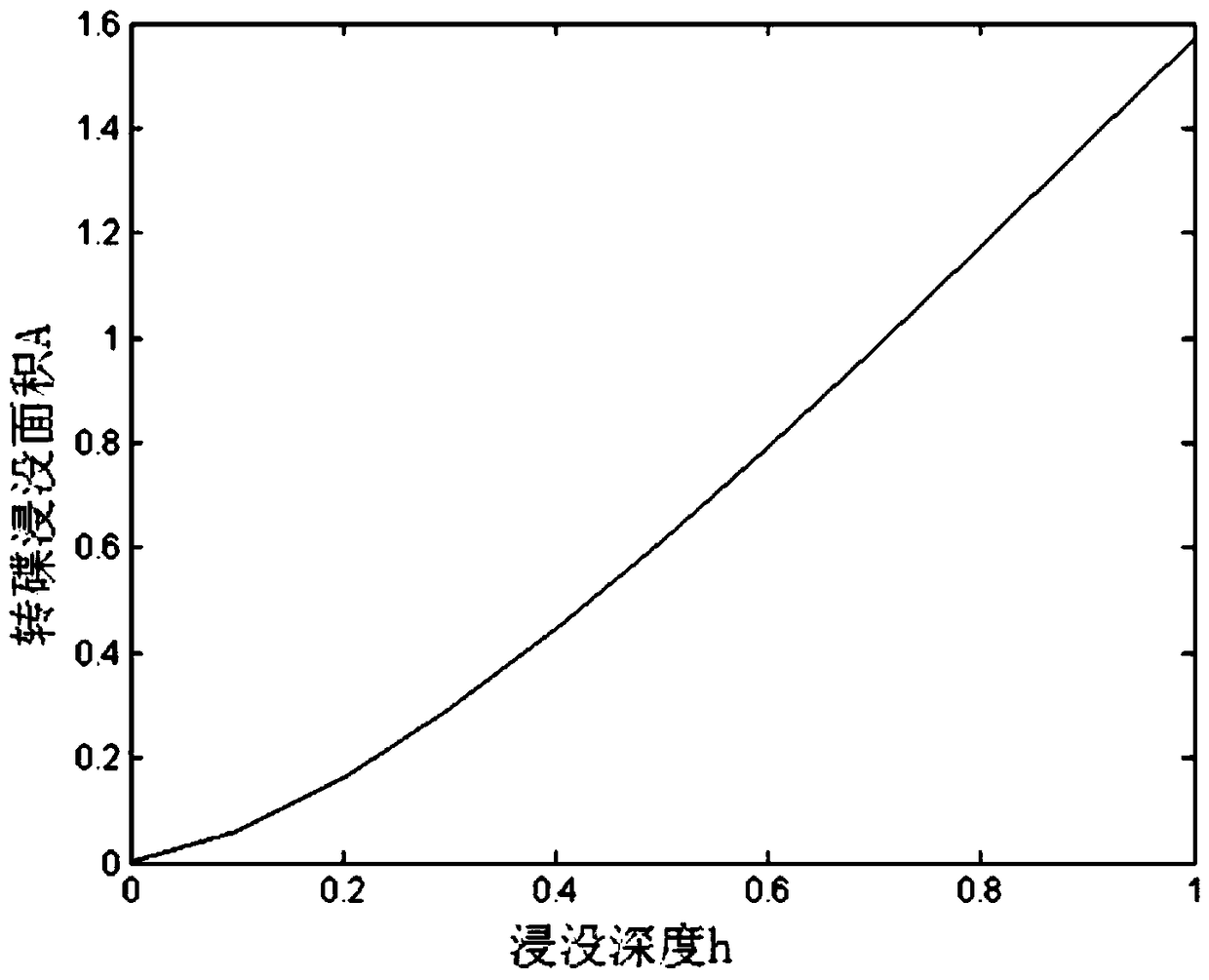

[0132] The equipment structure is as follows: 8 rotating discs with a diameter of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com