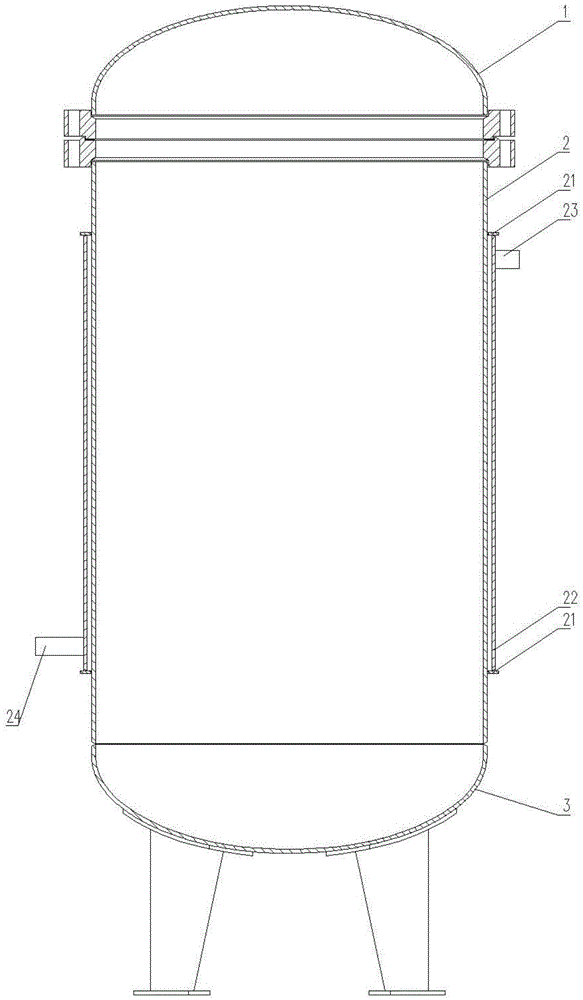

Water-cooling containment simulation device

A simulation device and containment technology, which is applied in the field of water-cooled containment simulation devices, can solve the problems of no containment wall cooling, enhanced containment steam condensation, and the containment model cannot simulate the passive containment cooling system well, etc. Achieve good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

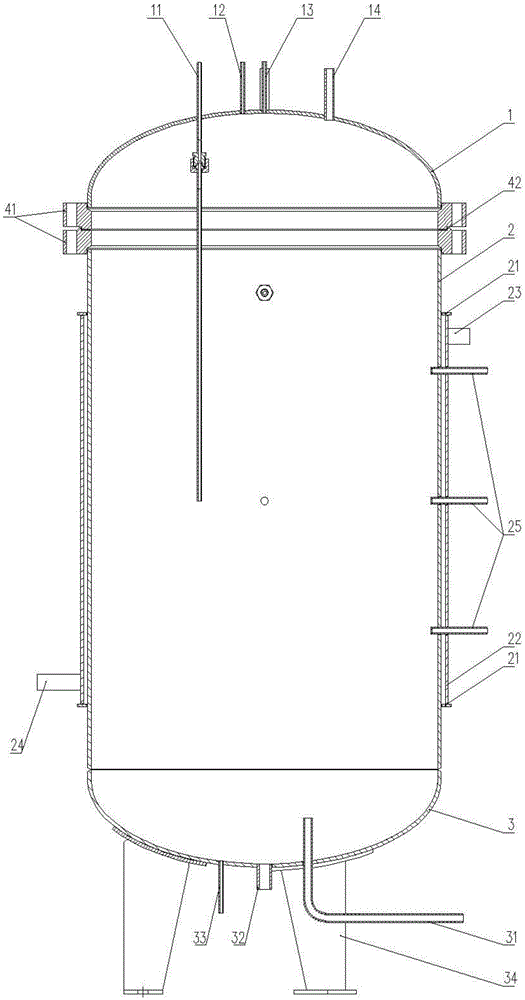

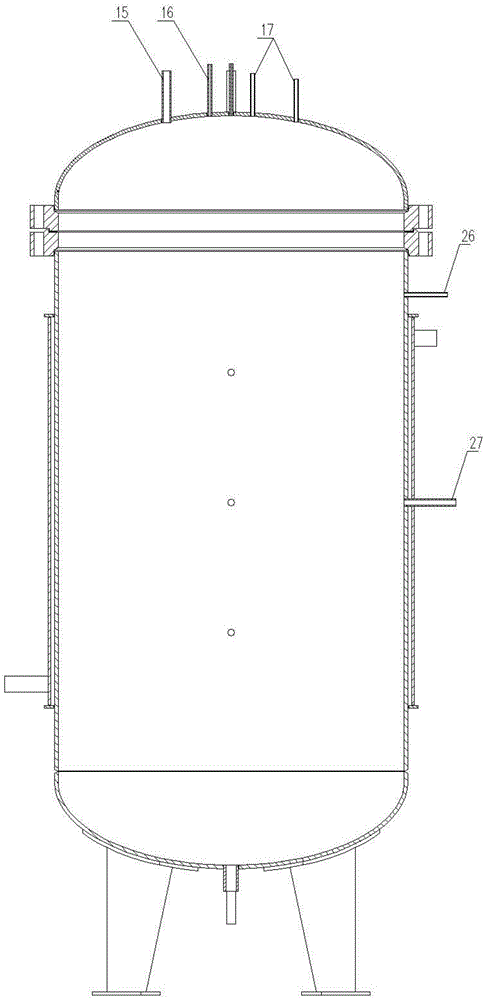

[0032] Like the water-cooled containment simulation device described above, this embodiment differs from it in that a vacuum connection 12 is provided on the top of the upper head 1, and the vacuum connection 12 is externally connected to a vacuum pump to evacuate the inside of the casing. Since this test uses different gases as carriers to bring simulated aerosol particles into the inner space of the housing, different gases include nitrogen, helium, argon, etc., in order to determine the influence of different carriers on the distribution of aerosol particles, Before the aerosol is input, it is necessary to vacuumize the inside of the housing to minimize the influence of air content on the test results. Vacuumize before the start of the test, and the aerosol will not be ventilated until the vacuum degree meets the requirements.

Embodiment 2

[0034] Like the water-cooled containment simulation device described above, the difference of this embodiment is that the bottom of the lower head 3 is provided with a steam inlet connecting pipe 31, and a steam generator (not shown in the figure) passes through the steam inlet connecting pipe 31 It is connected with the casing, and the generated steam with specific parameters is passed into the casing, simulating the water vapor environment in the safety casing after the main circuit coolant boils under the reactor accident condition.

Embodiment 3

[0036] Like the water-cooled containment simulation device described above, the present embodiment differs from it in that the top of the upper head 1 is provided with a hygrometer connecting pipe 14, and a hygrometer passes through the hygrometer (not shown in the figure) connecting pipe 14 and The housing is connected to measure the humidity of the air and water vapor mixture in the inner space of the housing.

[0037] The hygrometer connects the sampling line and installs the relative humidity probe in the connection pipe 14 of the hygrometer. The aerosol diffusion swimming test is to study the diffusion mechanism of the aerosol in a steam environment, so it is necessary to pass water vapor to the inside of the housing before the aerosol is ventilated. The function of the hygrometer is to measure the humidity of the air and water vapor mixture in the inner space of the housing, and the aerosol is introduced after the humidity meets the test requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com