Silicic acid mixtures and use thereof as insulation material

A technology for insulating materials and mixtures, which is applied in the field of silicic acid mixtures and their use as insulating materials, can solve the problems of reducing thermal insulation properties and mechanical stability, and achieve the effect of good thermal insulation properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

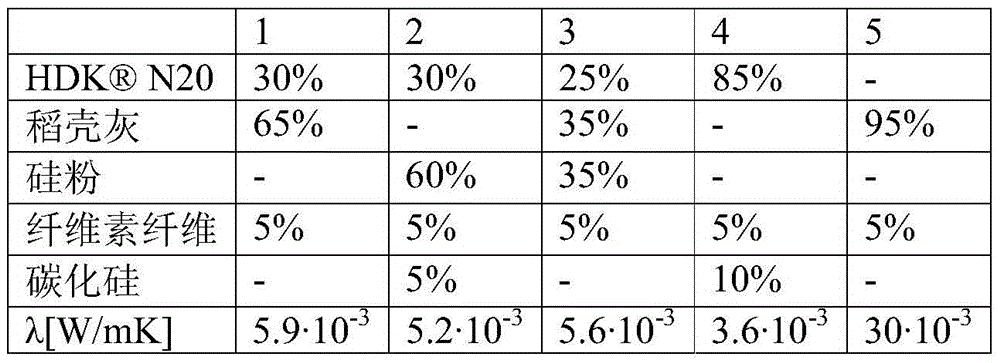

[0067] Preparation of fumed silica by mixing equipment (Dispermat VL60) from Getzmann N20 (WackerChemie AG, Burghausen), rice hull ash (produced by burning the residue obtained during the milling of rice obtained from PatumRiceMillandGranary, AmphurMueng, Thailand) and cellulose fibers ( Textilwerke, Schenkenzell, chopped to 6 mm) powder mixture. With a total amount of 800g, the percentages are as follows:

[0068] 30% by weight N20

[0069] 65% rice hull ash by weight

[0070] 5% by weight of cellulose fibers

[0071] By first introducing the mixture into a non-woven bag (polypropylene, weight per unit area 27 g / m 2 , Kreykamp GmbH, Nettetal) and which were closed by means of heat welding clamps HZ (230V, 540W, Kopp, Reichenbach), the mixture obtained was processed to manufacture vacuum-insulated panels. Drying was then performed at 55° C. for 10 hours in a Kelvitron drying oven (Heraeus, Hanau). The filled and dried nonwoven bag was then introduced into a sealing f...

Embodiment 2

[0073] According to the detailed description in Example 1, the following mixture was used for the production of VIP:

[0074] 30% by weight N20

[0075] 60% silica fume by weight

[0076] 5% silicon carbide by weight

[0077] 5% by weight of cellulose fibers

[0078] The results of the thermal conductivity measurements at 10°C are again shown in Table 1.

Embodiment 3

[0080] According to the detailed description in Example 1, the following mixture was used for the production of VIP:

[0081] 25% by weight N20

[0082] 35% rice hull ash by weight

[0083] 35% silica fume by weight

[0084] 5% by weight of cellulose fibers

[0085] In Table 1 the results of the thermal conductivity measurement at 10°C are shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com