High-calcium milk and production method thereof

A milk, high calcium technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of good marketization prospects, poor product stability, and inability to continuously produce pipelines, etc., and achieve good marketization prospects and strong stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

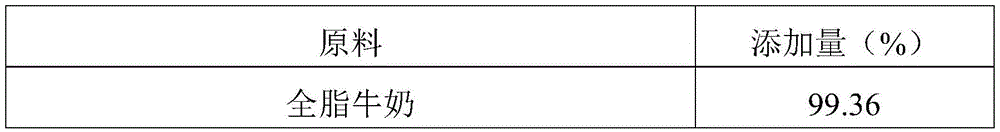

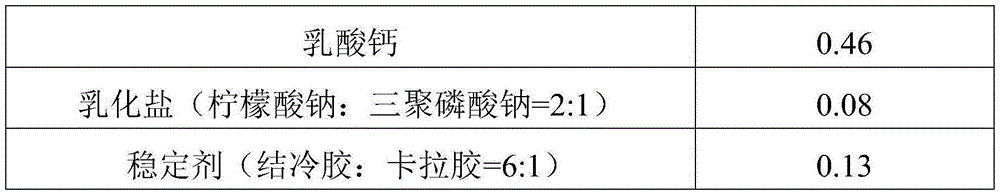

[0044] 1. Raw material formula (see Table 1):

[0045] The raw material formula of table 1 embodiment 1

[0046]

[0047]

[0048] Preparation steps:

[0049] (1) Mix and dissolve the ionic calcium-containing compound and emulsified salt in drinking water (dissolution temperature 70°C), heat and stir for 10 minutes, then cool to 25°C to obtain a mixed solution A;

[0050] (2) Heat the milk to 70°C and mix it with a stabilizer, heat it and stir it for 10 minutes, then cool it to 50°C to obtain the mixed solution B;

[0051] (3) The mixed solution B is evaporated to obtain the mixed solution C by flash evaporation, and the quality of the water is the consumption of drinking water in the step (1);

[0052] (4) Mixed solution C is homogeneous (70°C, 18MPa), UHT sterilized (130°C, 2 seconds), cooled (25°C) and then sprayed into mixed solution A (speed 5m / s), stirred for 5 minutes, cooled to 2°C to obtain a mixture D;

[0053] (5) After filling the mixed liquid D (the resi...

Embodiment 2

[0056] 1. Raw material formula (see Table 2):

[0057] The raw material formula of table 2 embodiment 2

[0058] raw material

Amount added (%)

skim milk

98.95

L-Calcium Lactate

0.58

Emulsifying salt (sodium citrate: sodium tripolyphosphate = 3:1)

0.12

Stabilizer (microcrystalline cellulose:carrageenan=10:1)

0.35

[0059] Preparation steps:

[0060] (1) Mix and dissolve the ionic calcium-containing compound and emulsified salt in drinking water (dissolution temperature 80°C), heat and stir for 15 minutes, then cool to 30°C to obtain a mixed solution A;

[0061] (2) Warm up the milk to 80°C and mix it with a stabilizer, heat it and stir it for 15 minutes, then cool it to 55°C to obtain the mixed liquid B;

[0062] (3) mixed solution B is obtained mixed solution C by evaporation of water by falling film concentration method, and the quality of described moisture is the consumption of drinking water in step (1);

...

Embodiment 3

[0067] 1. Raw material formula (see Table 3):

[0068] The raw material formula of table 3 embodiment 3

[0069] raw material

Amount added (%)

low fat milk

99.10

L-Calcium Lactate

0.46

Emulsifying salt (sodium citrate: sodium tripolyphosphate = 5:2)

0.12

Stabilizer (microcrystalline cellulose:carrageenan=15:1)

0.35

[0070] Preparation steps:

[0071] (1) Mix and dissolve the ionic calcium-containing compound and emulsified salt in drinking water (dissolution temperature 70°C), heat and stir for 15 minutes, then cool to 30°C to obtain a mixed solution A;

[0072] (2) Warm up the milk to 70°C and mix it with a stabilizer, heat it and stir it for 15 minutes, then cool it to 55°C to obtain the mixed solution B;

[0073] (3) mixed solution B is obtained mixed solution C by evaporation of water by falling film concentration method, and the quality of described moisture is the consumption of drinking water in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com