Low-temperature preparation method of fine-grained material for drug-type cap

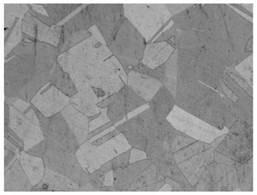

A drug-type cover and fine-grained technology, which is applied to explosive charges, offensive equipment, weapon accessories, etc., can solve the problems of difficulty in consistent control of process parameters, strict quality requirements, and lengthy procedures, and achieve industrial production and extrusion. The effect of small compression deformation force and overcoming the uneven distribution of grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

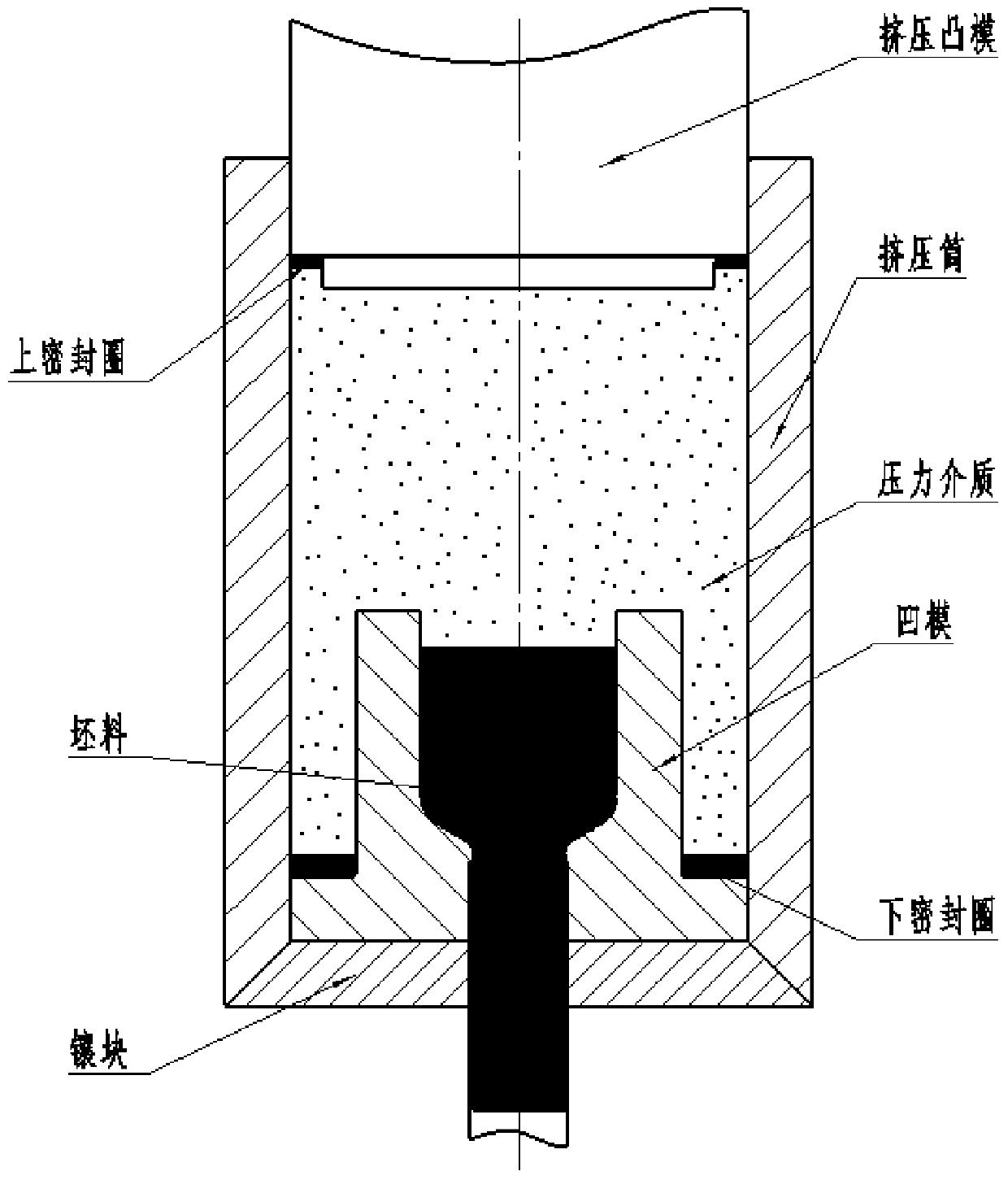

[0030] Taking a typical double-cone copper liner as an example, the liner has a diameter of φ88mm, a height of 84mm, an inner cone depth of 82mm, and a variable wall thickness of ≤2.5mm.

[0031] (1) Preparation of blanks: According to the theory of plastic forming and the principle of near-uniform plastic deformation, a certain machining allowance is considered on the outer surface of the medicine cover when designing the structure, and a φ25mm forming process boss is designed on the cone top of the medicine cover. ;Using UG and DEFORM software to simulate, analyze and optimize the forming process, and calculate the volume of the billet, select the extruded T2 copper rod of φ60mm as the raw material, blank the material and turn the outer surface to make a billet with a diameter of 58mm and a length of 80mm; The content of impurity elements in T2 copper rods is shown in Table 1:

[0032] Table 1 Content of impurity elements in T2 copper rods

[0033]

[0034] (2) Homogeniz...

Embodiment 2

[0038]Taking a typical single-cone copper liner as an example, the liner has a diameter of φ60mm, a height of 45mm, an inner cone depth of 44.2mm, and a wall thickness of 1mm.

[0039] (1) Preparation of blanks: According to the theory of plastic forming and the principle of near-uniform plastic deformation, a certain machining allowance is considered on the outer surface of the medicine cover when designing the structure, and a φ16mm forming process boss is designed on the cone top of the medicine cover. ;Use UG and DEFORM software to simulate, analyze and optimize the forming process, and calculate the volume of the billet, select the extruded T2 copper rod with a diameter of 50mm as the raw material, cut the material and turn the outer surface to make a billet with a diameter of 48mm and a length of 50mm; The content of impurity elements in T2 copper rods is shown in Table 1:

[0040] Table 1 Content of impurity elements in T2 copper rods

[0041]

[0042] (2) Homogeniz...

Embodiment 3

[0046] Taking a typical single-cone copper liner as an example, the liner has a diameter of φ100mm, a height of 94mm, an inner cone depth of 92.6mm, and a wall thickness of variable wall thickness ≤ 2.8mm.

[0047] (1) Preparation of blanks: According to the theory of plastic forming and the principle of near-uniform plastic deformation, a certain machining allowance is considered on the outer surface of the medicine cover when designing the structure, and a φ25mm forming process boss is designed on the cone top of the medicine cover. ;Using UG and DEFORM software to simulate, analyze and optimize the forming process, and calculate the volume of the billet, select the extruded T2 copper rod of φ90mm as the raw material, blank the material and turn the outer surface to make a billet with a diameter of 88mm and a length of 80mm; The content of impurity elements in T2 copper rods is shown in Table 1:

[0048] Table 1 Content of impurity elements in T2 copper rods

[0049]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com