Profile machining center

A processing center and profile technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of limiting the processing range of workpieces, not solving rigid problems, and long processing time, so as to reduce labor intensity and production costs , Improve the efficiency of profile processing and improve the overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

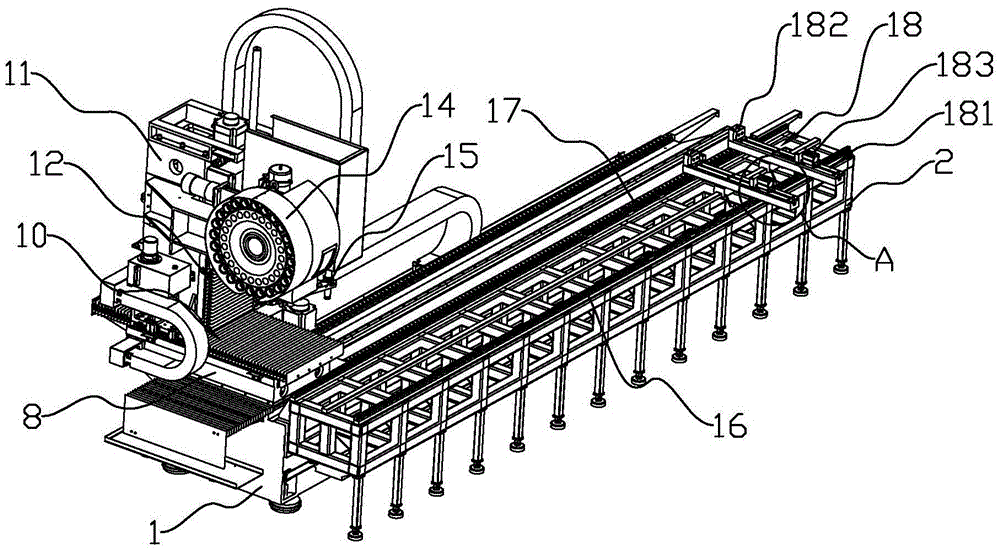

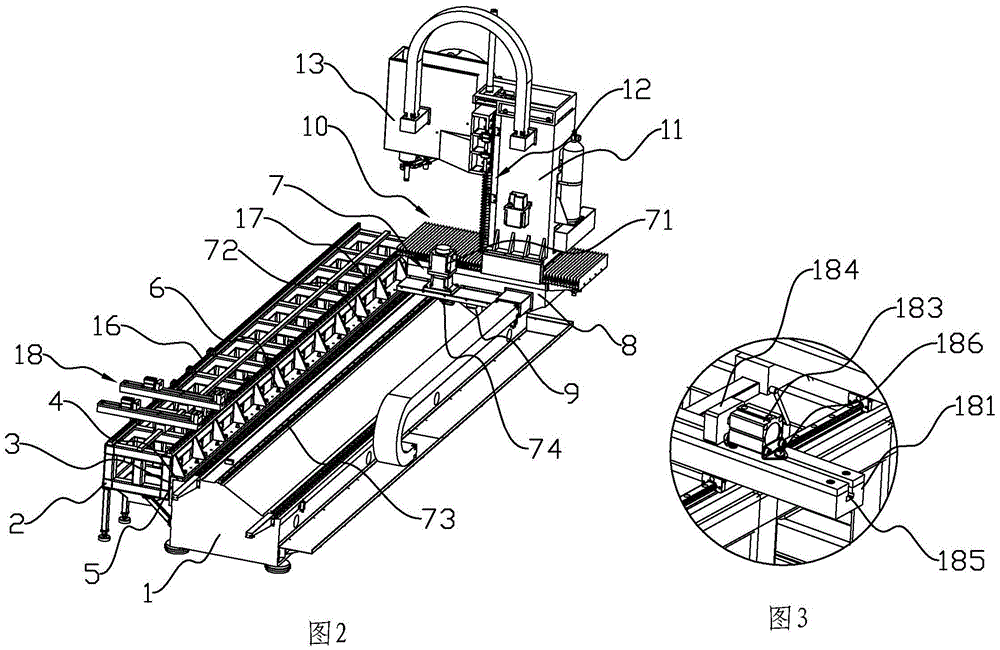

[0013] refer to figure 1 , figure 2 , a profile processing center of the present invention, comprising a base 1, the base 1 is formed by integral casting of metal, its transverse section is trapezoidal, a steel frame workbench 2 is connected to the front of the base 1, and the steel frame workbench 2 The side is provided with a right-angled connector 3, and the base 1 is respectively provided with first and second datum planes 4, 5 corresponding to the two right-angled sides of the right-angled connector 3, and several screws 6 pass through the right-angled connector. The two right-angled sides of the piece 3 are respectively connected and fixed with the first and second reference planes 4 and 5, and the base 1 is provided with a Y-axis support platform 8 driven by an X-axis transmission mechanism 7 and can move longitudinally. The Y-axis support platform The lower part of the 8 is provided with a saddle 9 that cooperates with the rear inclined surface of the trapezoid to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com