Assembly method of vacuum drainage system for mine shaft

A vacuum drainage and assembly method technology, applied in drainage, safety devices, mining equipment, etc., can solve problems such as insufficient water storage capacity, limited suction of water pumps, complex structure installation, etc., and achieve long-term safe and reliable operation. Maintenance workload Small, low-cost production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

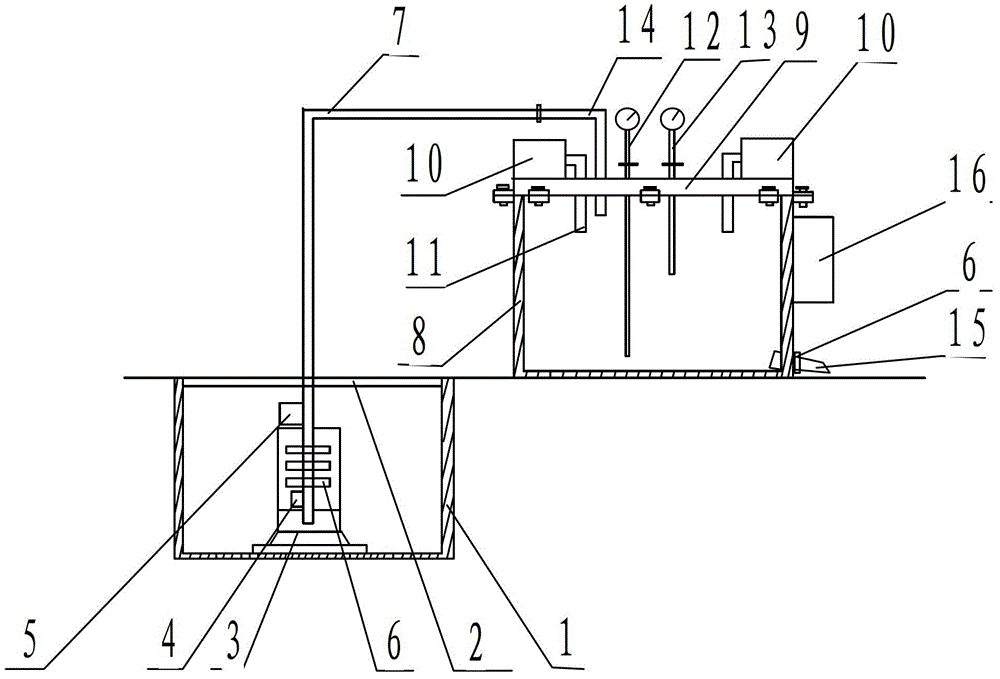

[0022] A support 3 is set at the bottom of the cement pool 1 in the mine, a vacuum pumping pipe 7 is set on the support 3, and a grate 2 is set above the cement pool 1; a vacuum box 8 is set on the ground, and a top plate 9 is set above the vacuum box 8, and the top plate 9 corresponds to the vacuum box 8 Setting, set multiple sets of fixing seats at the junction of the top plate 9 and the vacuum box 8, and fix them with bolts; vacuum pumps 10 are arranged on both sides above the top plate 9, and the suction port 11 of the vacuum pump 10 is set in the vacuum box 8 through the reserved hole of the top plate 9; A controller 16 is arranged on one side of the vacuum box 8 .

Embodiment 2

[0024] An inductor 4 is arranged above the water outlet of the vacuum suction pipe 7, a water level alarm 5 is arranged above the sensor 4 of the vacuum suction pipe 7, and at least three control valves 6 are arranged between the sensor 4 and the water level alarm 5; Set a liquid level indicator 12 and a vacuum gauge 13, set a water inlet elbow 14 on the top plate 9, connect the water inlet elbow 14 to the vacuum suction pipe 7, set a drain pipe 15 at the bottom of the vacuum box 8, and set a control valve on the drain pipe 15 6.

Embodiment 3

[0026] Vacuum suction pipe 7, vacuum box 8, top plate 9, water inlet elbow 14, drain pipe 15 are made of low carbon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com