Vibration control method for tool sharpening of grating ruling

A grating marking and cutting tool technology, which is applied in the directions of automatic grinding control device, workpiece feed movement control, grinding drive device, etc., to achieve the effect of improving smoothness, cutting edge quality and grinding efficiency, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

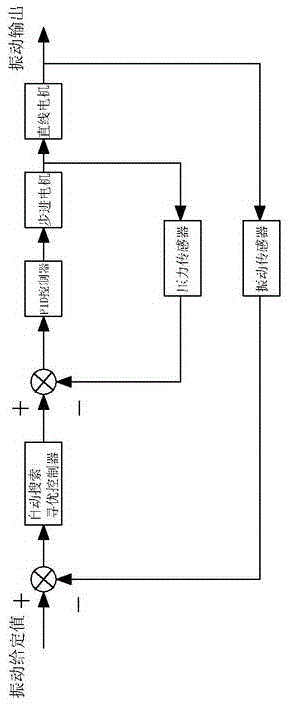

[0015] see figure 1 Shown, method of the present invention comprises the following steps:

[0016] 1. By adjusting the feed rate of the tool and the grinding load applied by the tool to the grinding disc, the vibration of the tool is controlled. The feed rate adjustment of the tool is completed by the feed mechanism, which is composed of a linear motor, an air-floating guide rail, a connecting mechanism, and a tool holder. Among them, the high-precision, high-rigidity rectangular air-bearing guide rail provides precise guidance for the tool feed because of its extremely small friction coefficient. The linear motor has a micron-level feed rate, which meets the requirements of the tool micro-feed; the tool load is adjusted It is completed by the tool loading mechanism. The loading mechanism is composed of a fixed self-weight end and an adjustable counterweight end. The fixed self-weight end includes the tool pendulum shaft, angle adjustment mechanism and air bearing guide rail; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com