Surface transverse-grinding process and manufacturing machine for solid wood floor

A technology of solid wood flooring and machinery, applied in the direction of manufacturing tools, abrasive belt grinders, metal processing equipment, etc., can solve the problems of low production efficiency, high labor intensity of workers, and poor working environment, so as to improve production efficiency and labor intensity of workers Small, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a basis for limiting the present invention.

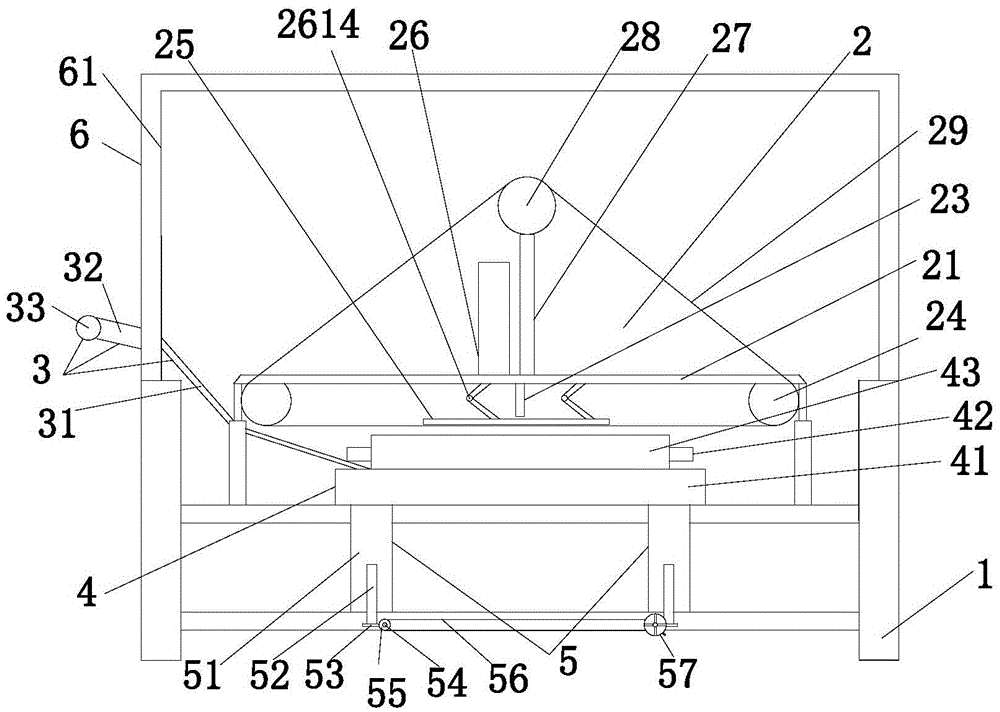

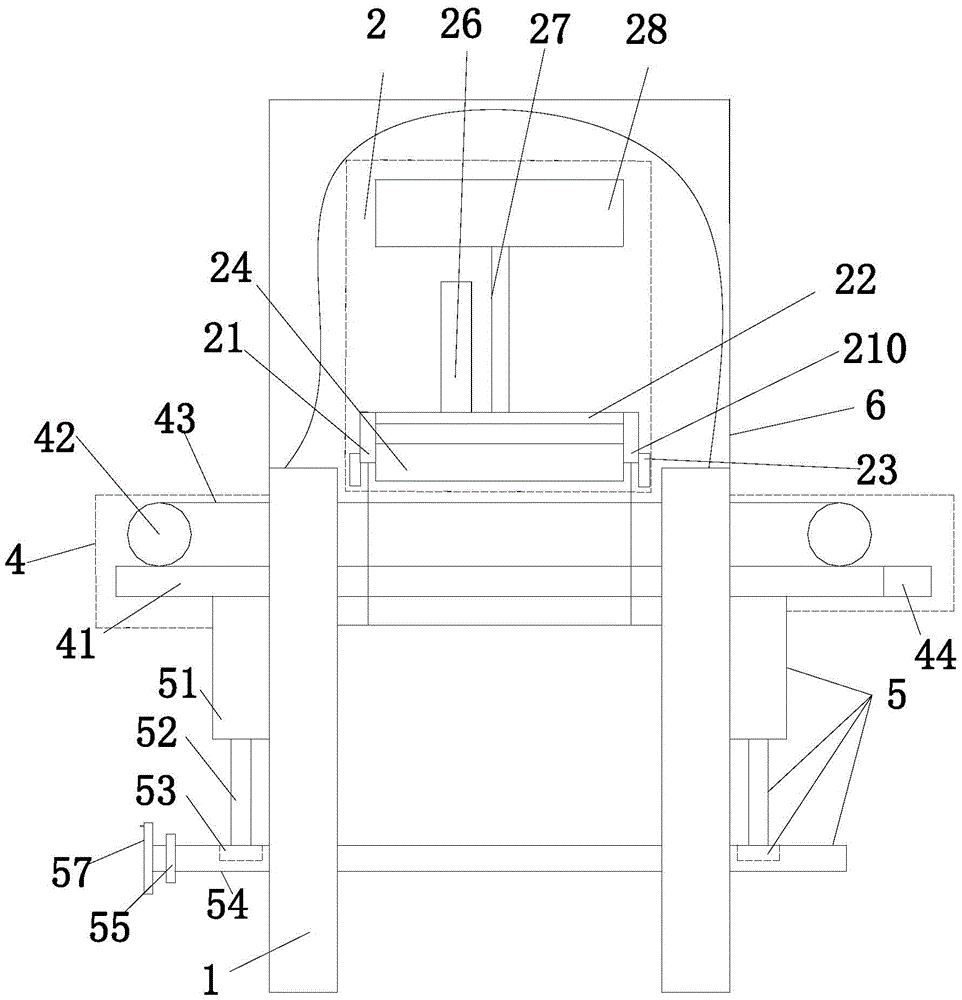

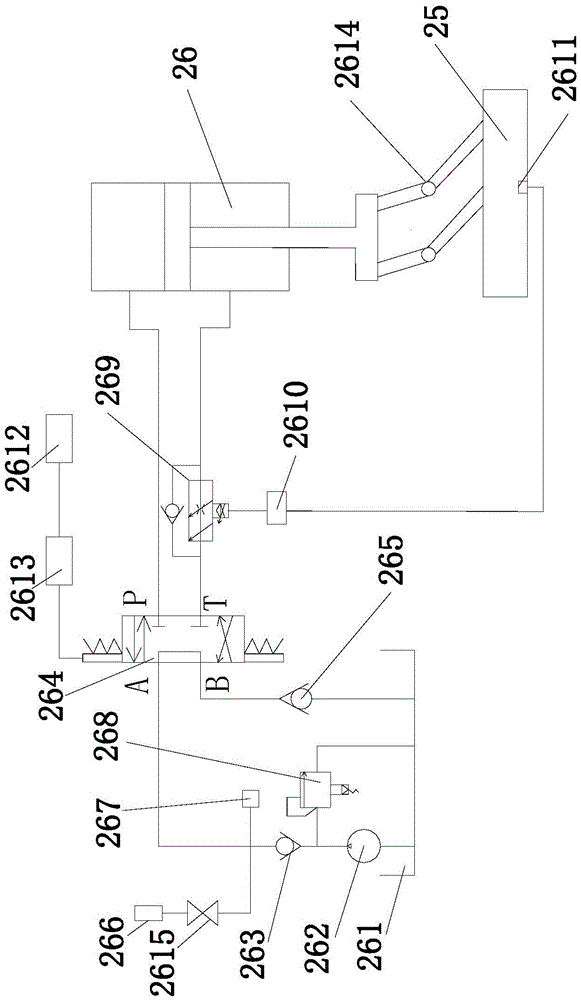

[0021] Example. The surface horizontal sanding process of solid wood flooring is to carry out horizontal sanding treatment on the solid wood floor through the mutual cooperation of the downward pressure power mechanism and the conveying device; place the solid wood floor on the conveying device, first open the conveying device, and adjust the solid wood floor and the downward pressure force on the conveying device The distance between the mechanisms, and then turn on the down-pressing power mechanism, the solid wood floor moves with the conveying device, and after being compressed by the pressure wheel, it enters the lower position of the belt, and the belt with horizontal sand grains on the outer surface performs horizontal sand treatment on the solid wood floor. At the same time, the pressing boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com