Opening device for electrode insulation shunting strips of solar cell module

A solar cell and electrode insulation technology, which is applied in metal processing and other directions, can solve problems such as low production efficiency, failure to meet the opening requirements, and affecting the assembly progress of the assembly line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

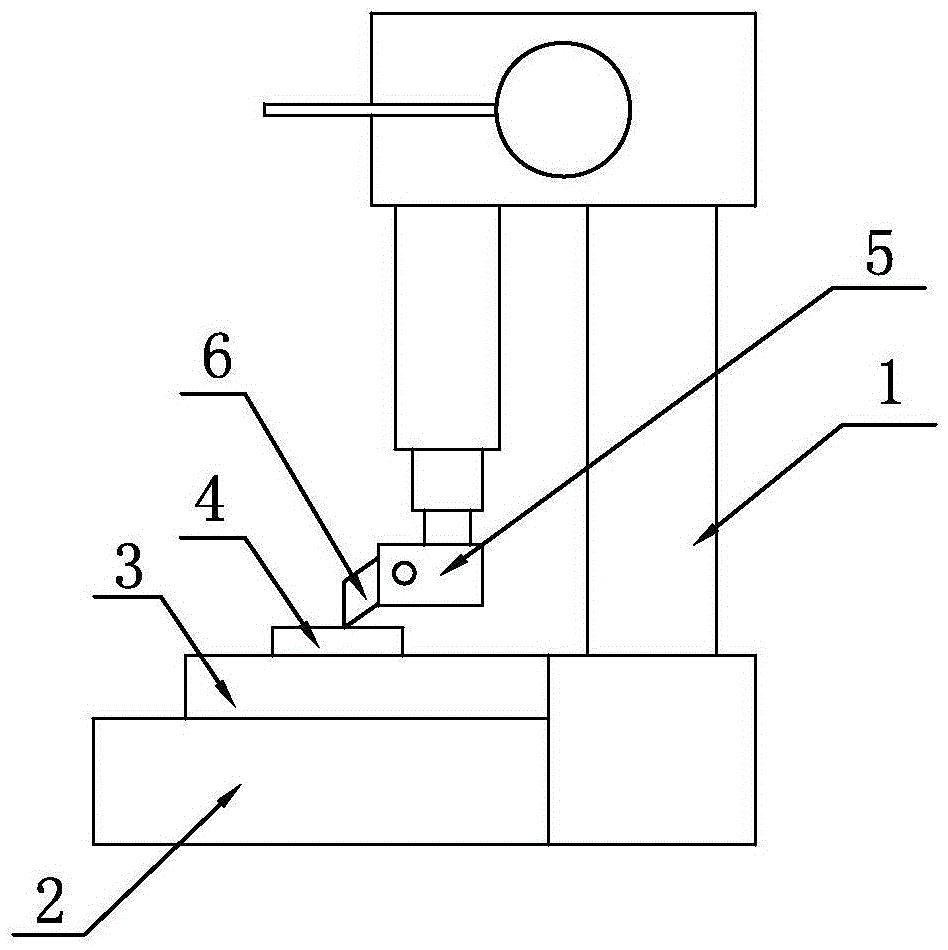

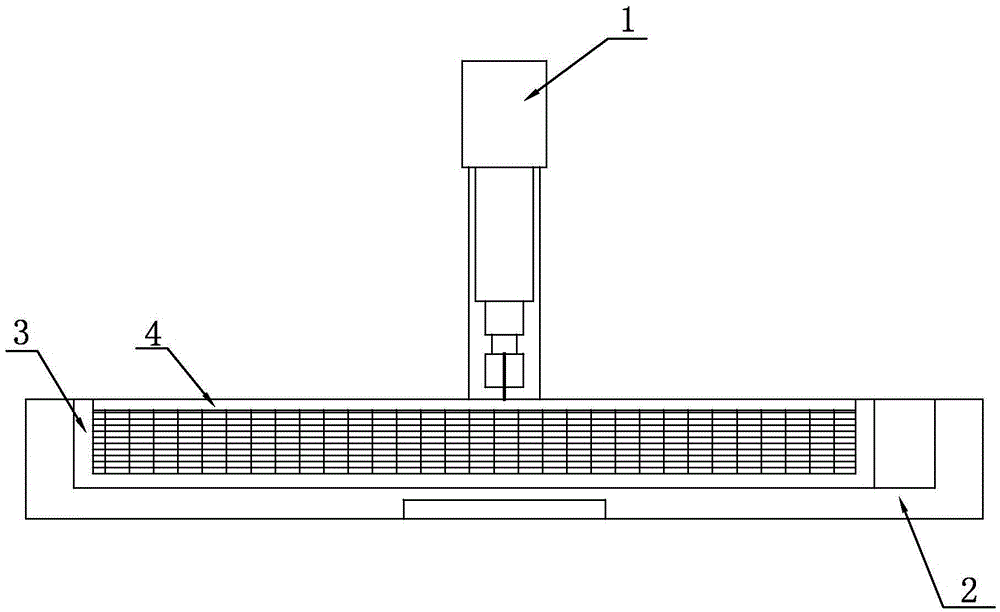

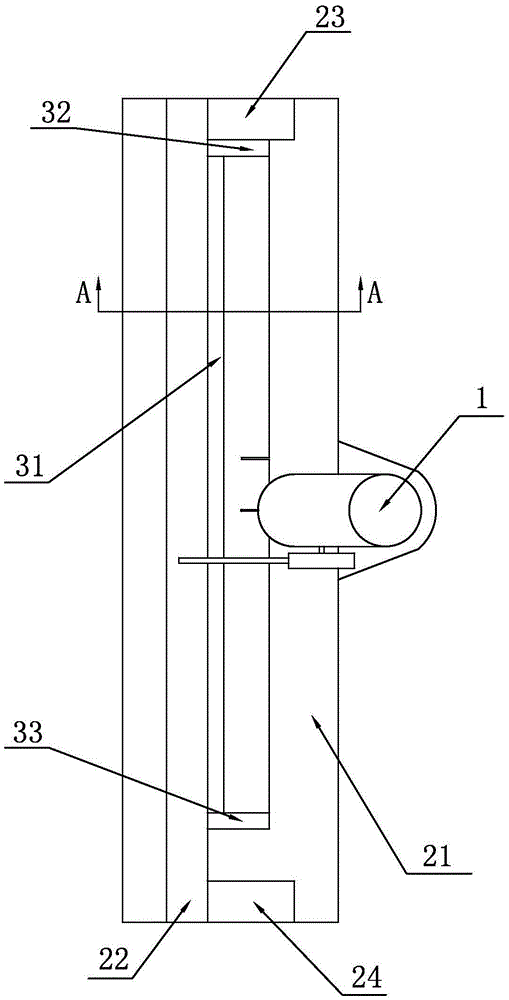

[0021] Embodiment 1: a solar cell module electrode insulation shunt strip opening equipment, which includes a manual press 1, a clamping body 2, an insulating strip moving and fixing frame 3, an opening template 4, a tool clamping device 5 and an opening blade 6. The clamping body 2 is composed of a bottom plate 21, a lateral limit block 22, a left limit block 23 and a right limit block 24. The bottom plate 21 is horizontally fixed on the basic platform of the manual press 1, and the manual press 1 The telescopic rod is perpendicular to the bottom plate 21, and the lateral limit block 22, the left limit block 23 and the right limit block 24 are all fixed on the bottom plate 21, wherein the left limit block 23 and the right limit block 24 are respectively It is fixed on both ends of the lateral limit block 22 and is perpendicular to the lateral limit block 22. The bottom plate 21, the lateral limit block 22, the left limit block 23 and the right limit block 24 form a space that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com