A kind of protein treatment method in potato starch production wastewater

A potato starch and production wastewater technology, which is applied in food industry wastewater treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve problems such as high cost, unstable operation, complicated process, etc., and achieve extraction utilization rate Improve and ensure the effect of protein precipitation and efficient use of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

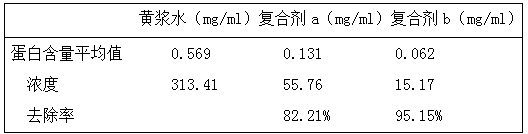

Embodiment 1

[0029] A. Filter the yellow slurry water produced by the potato starch processing plant through a 50-mesh filter, take 1L of waste water, and adjust the pH to about 4~5 with hydrochloric acid;

[0030] B, urea, polyacrylamide, CaCl 2 According to the ratio of 13mg, 8mg, 5mg, make a mixed solution, add it to 1L waste water, stir slowly for 1~2 minutes, and let it stand for 1 hour.

[0031] C. Add polyaluminum chloride at a concentration of 500mg / L, stir slowly, let stand for 1 hour, and take out the supernatant;

[0032] D. The precipitate is dehydrated, spray-dried and crushed to obtain a high value-added crude protein by-product.

Embodiment 2

[0034] A. Filter the yellow slurry water produced by the potato starch processing plant through a 100-mesh filter, take 1L of waste water, and adjust the pH to about 4~5 with glacial acetic acid;

[0035] B, urea, polyacrylamide, CaCl 2 According to the ratio of 15mg, 10mg, 6mg, make a mixed solution, add it to 1L waste water, stir slowly for 1~2 minutes, and let it stand for 1 hour.

[0036] C. Add polyaluminum chloride at a concentration of 500mg / L, stir slowly, let stand for 1 hour, and take out the supernatant;

[0037] D. The precipitate is dehydrated, spray-dried and crushed to obtain a high value-added crude protein by-product.

Embodiment 3

[0039] A. Filter the yellow slurry water produced by the potato starch processing plant through a 200-mesh filter, take 1L of waste water, and adjust the pH to about 4~5 with glacial acetic acid;

[0040] B, urea, polyacrylamide, CaCl 2 According to the ratio of 18mg, 13mg, 7mg, make a mixed solution, add it to 1L wastewater, stir slowly for 1~2 minutes, and let it stand for 1 hour.

[0041] C. Add polyaluminum chloride at a concentration of 500mg / L, stir slowly, let stand for 1 hour, and take out the supernatant;

[0042] D. The precipitate is dehydrated, spray-dried and crushed to obtain a high value-added crude protein by-product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com