Method for preparing long-chain alkane through hydrolysis and in-situ hydrogenation and decarboxylation of micro-algal oil

An in-situ hydrogenation and long-chain alkane technology, applied in the field of oil degradation, can solve the problems of further improvement and low total mass yield of the three-step reaction, and achieve the effect of convenient product separation, strong environmental adaptability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

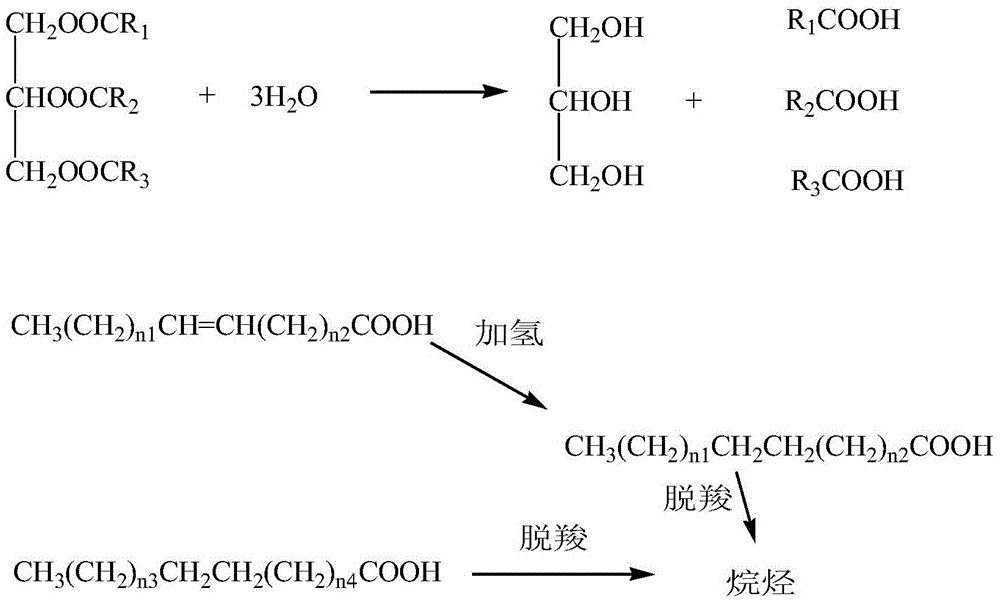

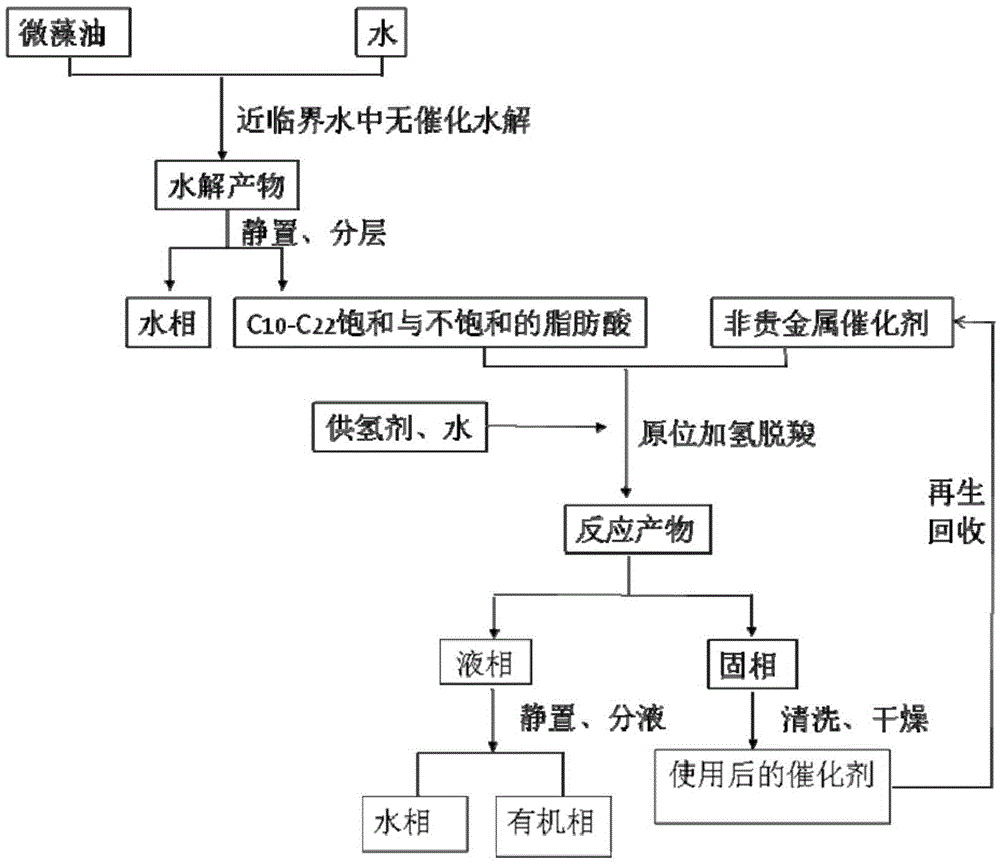

Method used

Image

Examples

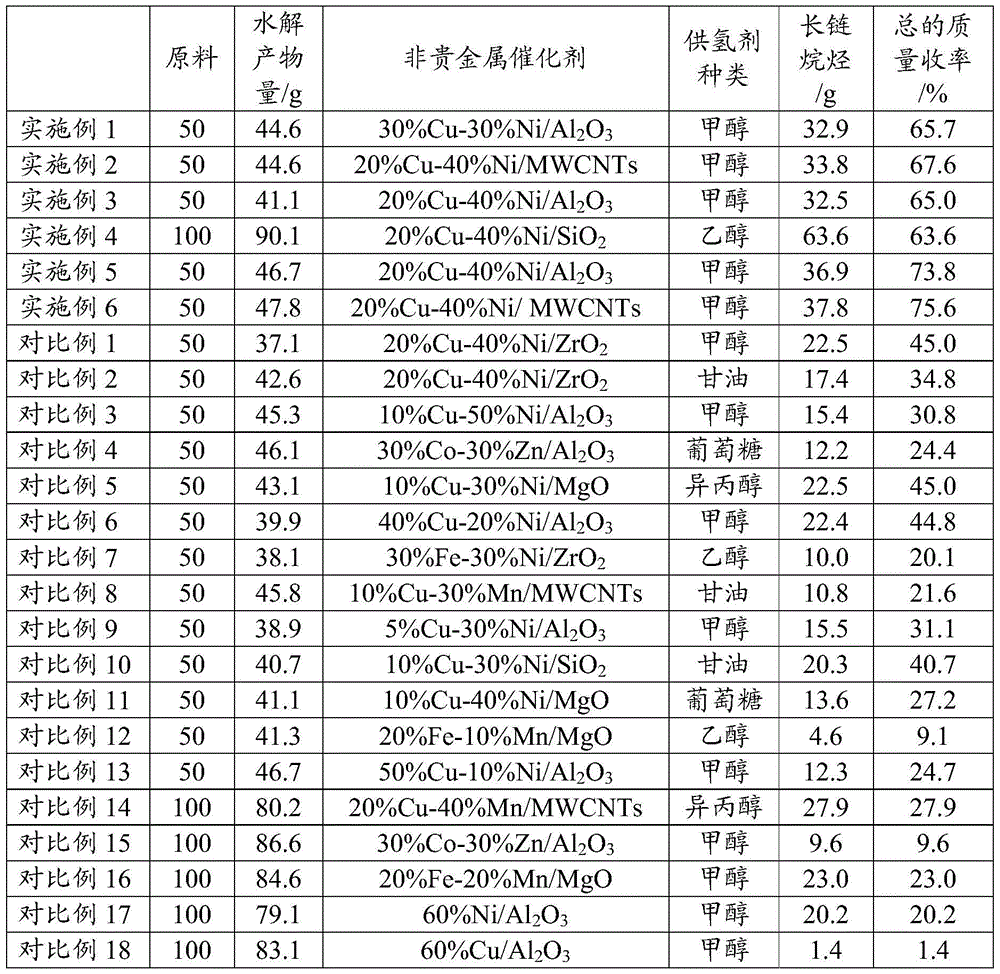

Embodiment 1

[0042] Add 50g of microalgae oil and 50g of deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 250 ° C for 5 hours of hydrolysis reaction, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 10 ~C 22 fatty acid) 44.6g; 44.6g hydrolyzate and 8.9g30%Cu-30%Ni / Al 2 o 3 Catalyst, 13.3g of methanol, 240mL of deionized water were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 330°C for 3 hours, and after the reaction was completed, the reaction product was cooled and filtered; the liquid phase product was left to separate and separated into After the organic phase was fixed to volume with acetone, it was analyzed by GC-FID, and the calculated mass of long-chain alkanes was 32.9 g, and the total mass yield of long-chain alkanes was 65.7%.

Embodiment 2

[0044] Add 50g of microalgal oil and 100g of deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 220 ° C for 10 hours of hydrolysis reaction, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 10 ~C 22 fatty acid) 44.6g; 44.6g hydrolyzate and 8.5g20%Cu-40%Ni / MWCNTs catalyst, 15.1g methanol, 210mL deionized water were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 330°C for 1 hour , after the reaction was completed, the reaction product was cooled and filtered; the liquid phase product was left to stand for stratification, and the organic phase was separated and analyzed by GC-FID after constant volume with acetone, and the calculated quality of long-chain alkanes was 33.8g, and the total amount of long-chain alkanes The mass yield is 67.6%. .

Embodiment 3

[0046] Add 50g of microalgae oil and 150g of deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 230 ° C for 6 hours of hydrolysis reaction, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 10 ~C 22 fatty acid) 41.1g; 41.1g hydrolyzate and 12.3g20%Cu-40%Ni / Al 2 o 3 Catalyst, 12g of methanol, 200mL of deionized water were added to a 500mL intermittent high-temperature and high-pressure reactor, and the temperature was raised to 330°C for 1 hour. After the reaction was completed, the reaction product was cooled and filtered; After the phase was fixed to volume with acetone, it was analyzed by GC-FID, and the calculated mass of long-chain alkanes was 32.5 g, and the total mass yield of long-chain alkanes was 65.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com