Simulated moving bed reaction and regeneration device for solid acid alkylation and method for raw material reaction and catalyst regeneration

A technology for simulating moving bed and fixed bed reactors, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as insufficient contact, reaction efficiency needs to be improved, etc., to achieve full contact , frequent regeneration is easy to operate, and the effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

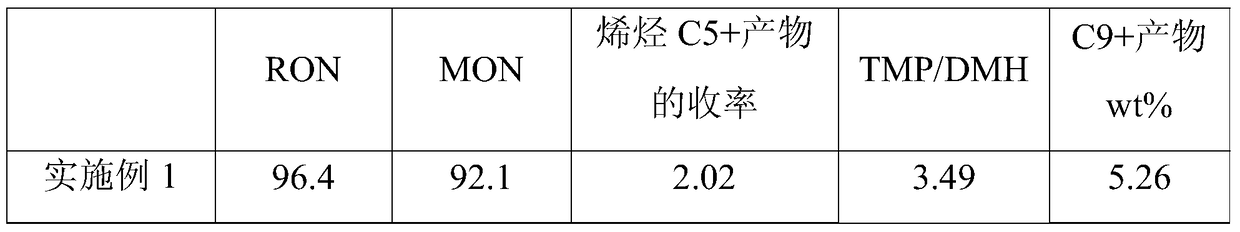

Embodiment 1

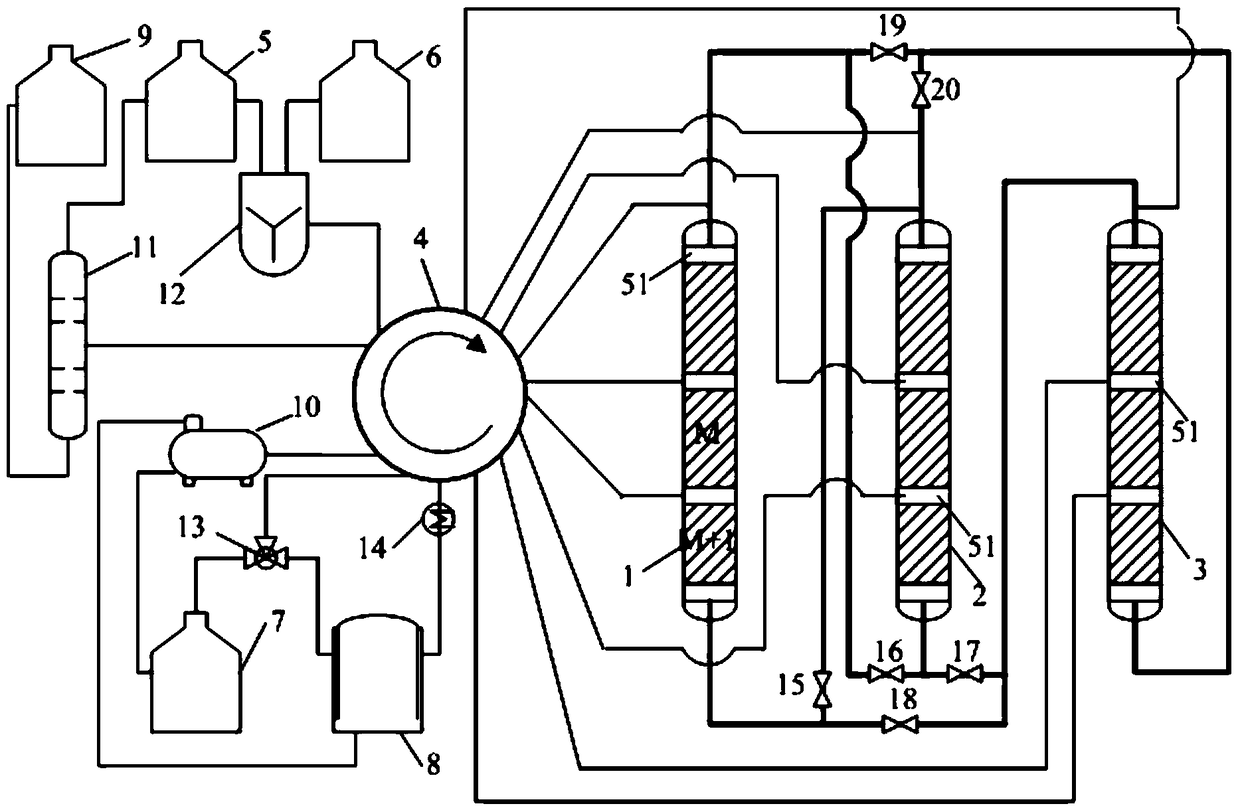

[0080] This embodiment is used to illustrate a simulated moving bed reaction and regeneration device for solid acid alkylation and a method for raw material reaction and catalyst regeneration for solid acid alkylation of the present invention.

[0081] Such as figure 1 As shown, the simulated moving bed reaction and regeneration device for solid acid alkylation of the present invention includes a raw material and product zone, a regenerated material zone, a rotary valve 4 and a countercurrent simulated moving bed reactor. Under the control of the rotary valve 4, The raw materials in the raw material and product zone are introduced into the countercurrent simulated moving bed reactor for alkylation reaction, the alkylation reaction product produced in the countercurrent simulated moving bed reactor is returned to the raw material and product zone, and the catalyst regeneration medium in the regenerated material zone is introduced into countercurrent The catalyst is regenerated in t...

Embodiment 2

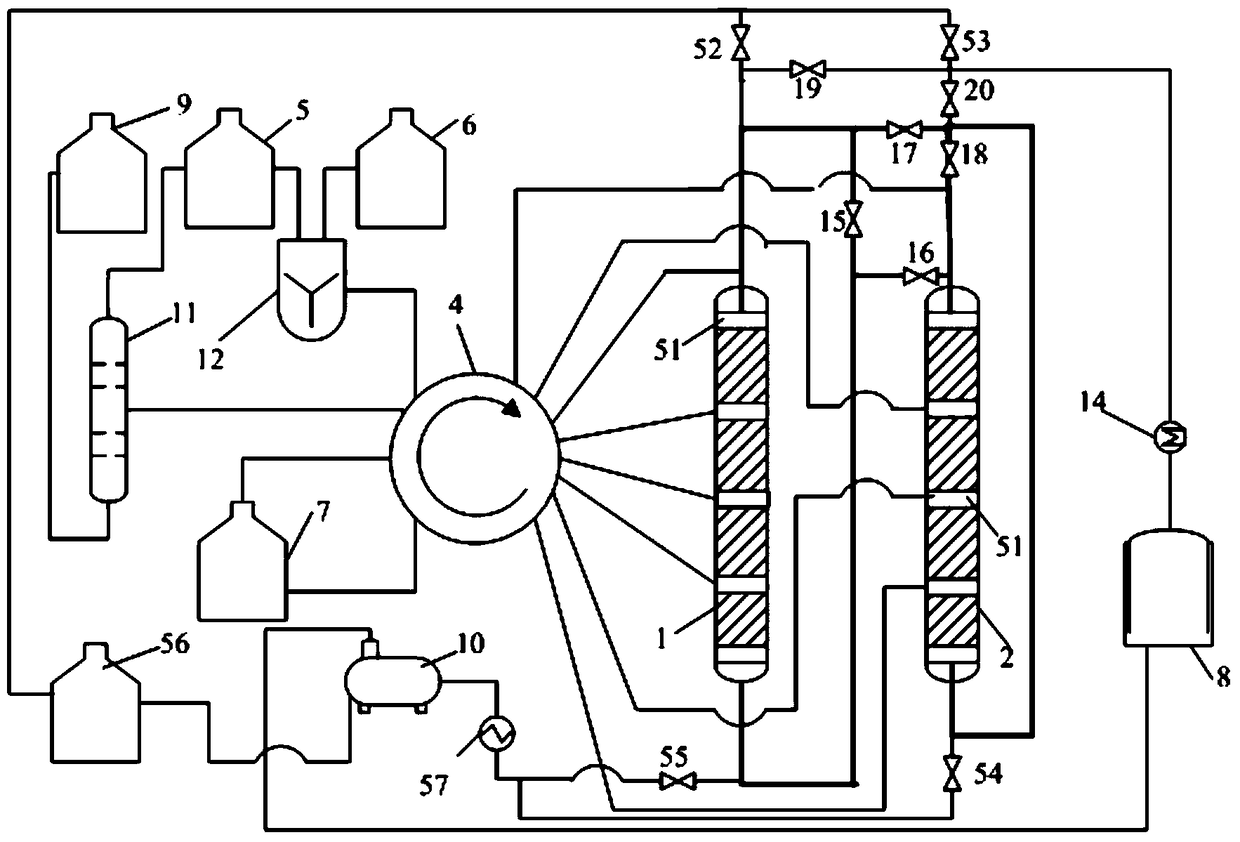

[0089] This embodiment is used to illustrate a simulated moving bed reaction and regeneration device for solid acid alkylation and a method for raw material reaction and catalyst regeneration for solid acid alkylation of the present invention.

[0090] Such as figure 2 As shown, the simulated moving bed reaction and regeneration device for solid acid alkylation of the present invention includes a raw material and product zone, a regenerated material zone, a rotary valve 4 and a countercurrent simulated moving bed reactor. Under the control of the rotary valve 4, The raw materials in the raw material and product zone are introduced into the countercurrent simulated moving bed reactor for alkylation reaction, the alkylation reaction product produced in the countercurrent simulated moving bed reactor is returned to the raw material and product zone, and the catalyst regeneration medium in the regenerated material zone is introduced into countercurrent The catalyst is regenerated in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com