Method of movably gasifying straw in batches with fixed beds to prepare tar and returning ash to field

A fixed-bed, mobile technology, applied in the field of comprehensive recovery and utilization of agricultural resources, can solve the problems of biomass heat transfer, difficult content of solid impurities in pyrolysis gas, complex overall structure of the device, and complex structure of the overall device, so as to avoid large straws. The effect of large-scale long-distance collection of transportation costs, simple operation, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

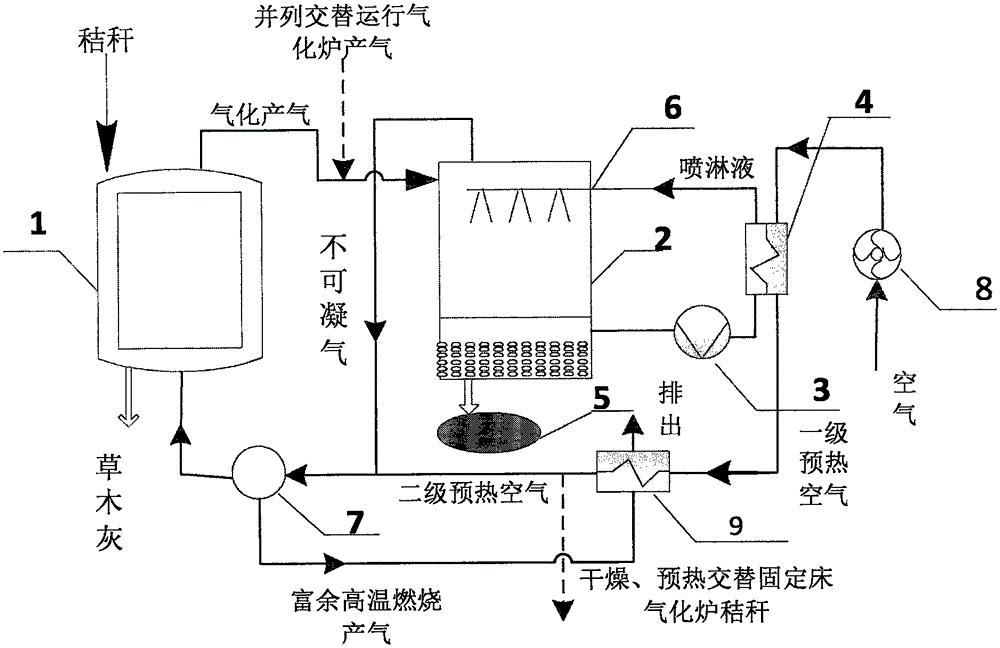

[0033] The invention provides a method for producing tar and plant ash by batch gasification of straw in a mobile fixed bed, such as figure 1 As shown, the outlet of updraft fixed bed reactor 1 is connected to the inlet of spray chamber 2, the outlet of spray liquid at the bottom of spray chamber 2 is connected to the inlet of circulation pump 3, and the outlet of circulation pump 3 is connected to the spray liquid of primary air preheater 4 Inlet, primary air preheater 4 spray liquid outlet is connected to spray pipe 6 inlet; fan 8 outlet is connected to primary air preheater 4 air inlet, primary air preheater 4 air outlet is connected to secondary air preheating The air inlet of the device 9, the air outlet of the secondary air preheater 9 is connected with the gasification non-condensable gas outlet of the spray chamber 2 and connected to the inlet of the low calorific value burner 7, and the outlet of the low calorific value burner 7 is connected to the updraft fixed bed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com