Alloy material used for aircraft toilet valve

A technology of alloy materials and toilets, which is applied in the field of alloy materials for aircraft toilet valves, can solve problems such as limited research, and achieve the effects of improving corrosion resistance, improving hardness and wear resistance, and increasing strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of alloy material used in aircraft toilet valve

[0039] Raw material chemical element composition mass percentage:

[0040] Carbon 0.63%, Manganese 0.88%, Phosphorus 0.040%, Sulfur 0.03%, Silicon 0.35%, Chromium 18.0%, Molybdenum 0.21%, Nickel 11.0%, Copper 0.28%, Zinc 0.39%, Cobalt 17.5%, Strontium 10%, Lanthanum 0.17% %, boron 1.50%, aluminum 0.29%, rhodium 0.018%, and the rest is iron.

[0041] The content of carbon is 0.63%, which ensures the basic mechanical strength of the alloy, but the ductility and toughness of the valve need to be improved, 0.17% of lanthanum, but the addition of lanthanum reduces the wear resistance of the valve, in order not to reduce the wear resistance , add 17.5% cobalt and 11.0% nickel, so that the ductility, toughness and wear resistance of the valve are further improved. Since iron, nickel and cobalt are infinitely soluble, α, γ and ε phases with different lattice structures can be obtained , In addition, carbon and cobalt fo...

Embodiment 2

[0046] A kind of alloy material used in aircraft toilet valve

[0047] Raw material chemical element composition mass percentage:

[0048] Carbon 0.60%, Manganese 0.65%, Phosphorus 0.035%, Sulfur 0.03%, Silicon 0.15%, Chromium 18.0%, Molybdenum 0.15%, Nickel 9.0%, Copper 0.21%, Zinc 0.31%, Cobalt 17.0%, Strontium 8.0%, Lanthanum 0.10% %, boron 0.50%, aluminum 0.10%, rhodium 0.01%, and the rest is iron.

[0049] The content of carbon is 0.60%, which ensures the basic mechanical strength of the alloy, but the ductility and toughness of the valve need to be improved. 0.10% lanthanum, but the addition of lanthanum reduces the wear resistance of the valve. In order not to reduce the wear resistance , add 17.0% cobalt and 9.0% nickel, so that the ductility, toughness and wear resistance of the valve are further improved. Since iron, nickel and cobalt are infinitely soluble, α, γ and ε phases with different lattice structures can be obtained , In addition, carbon and cobalt form a ...

Embodiment 3

[0054] A kind of alloy material used in aircraft toilet valve

[0055] Raw material chemical element composition mass percentage:

[0056] Carbon 1.0%, Manganese 1.10%, Phosphorus 0.045%, Sulfur 0.04%, Silicon 0.355%, Chromium 20.0%, Molybdenum 0.25%, Nickel 12.0%, Copper 0.30%, Zinc 0.42%, Cobalt 20.0%, Strontium 11.0%, Lanthanum 0.30% %, boron 3.0%, aluminum 0.50%, rhodium 0.03%, and the rest is iron.

[0057] The content of carbon is 1.0%, which ensures the basic mechanical strength of the alloy, but the ductility and toughness of the valve need to be improved. 0.30% lanthanum, but the addition of lanthanum reduces the wear resistance of the valve. In order not to reduce the wear resistance , add 20.0% cobalt and 12.0% nickel, so that the ductility, toughness and wear resistance of the valve are further improved. Since iron, nickel and cobalt are infinitely soluble, α, γ and ε phases with different lattice structures can be obtained , In addition, carbon and cobalt form a...

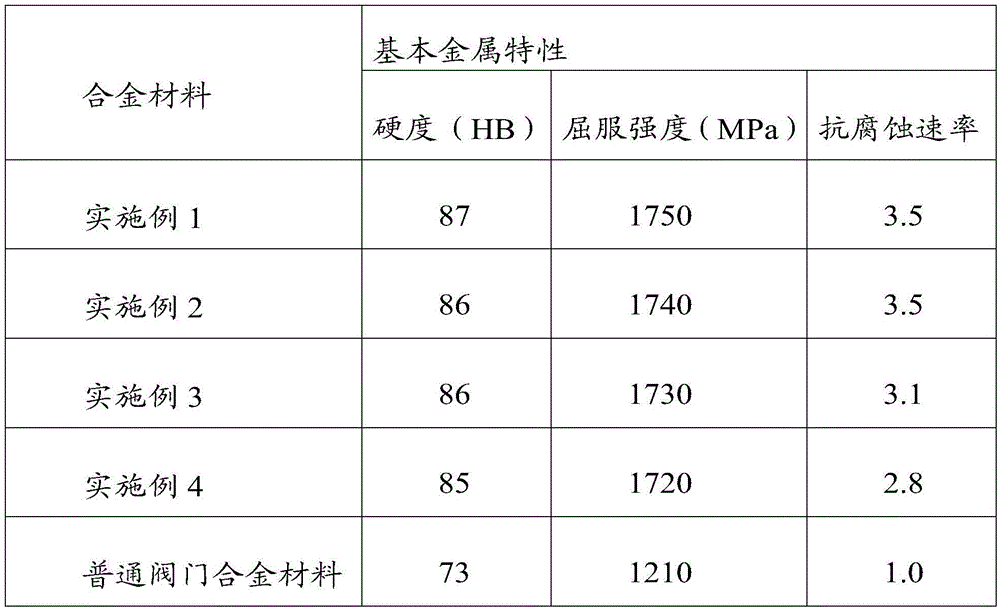

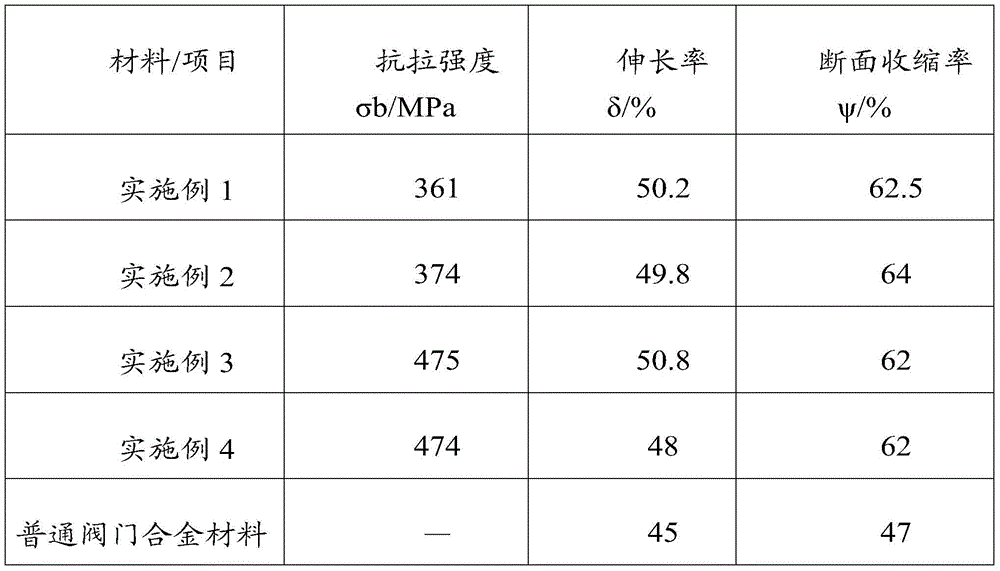

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com