Operation control method of fluid heating road snow-melting system

A technology of operation control and road, which is applied in the direction of auxiliary controller with auxiliary heating device and electric temperature control, etc. It can solve the problems of blind setting of system operating parameters and inability to effectively control the snow melting process, etc., and achieve good snow melting effect , Reduce system operating costs and reduce negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

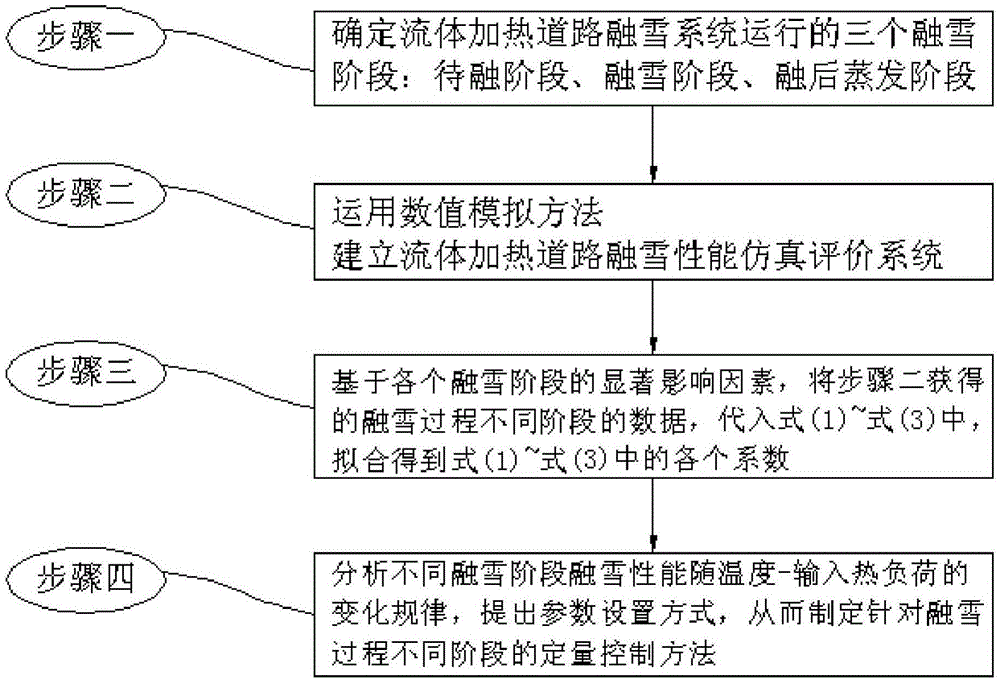

[0042] The operation control method of the fluid heating road snow melting system in this embodiment combines figure 1 Described, described method is realized through the following steps:

[0043] Step 1. Determine the three snowmelting stages of the fluid heating road snowmelting system: the stage to be melted, the snowmelt stage, and the evaporation stage after melting. Density represents the melting ability of road surface snow, and the average liquid-vapor phase change heat flux after melting represents the water evaporation capacity of road surface in the evaporation stage after melting;

[0044] Step 2. Using the numerical simulation method, establish a simulation evaluation system for the snow melting performance of fluid heating roads, and realize the accurate acquisition of the time to be melted, the average phase change heat flux during the snow melting process, and the average liquid-vapor phase change heat flux 5 hours after melting;

[0045] Step 3. Obtain releva...

specific Embodiment approach 2

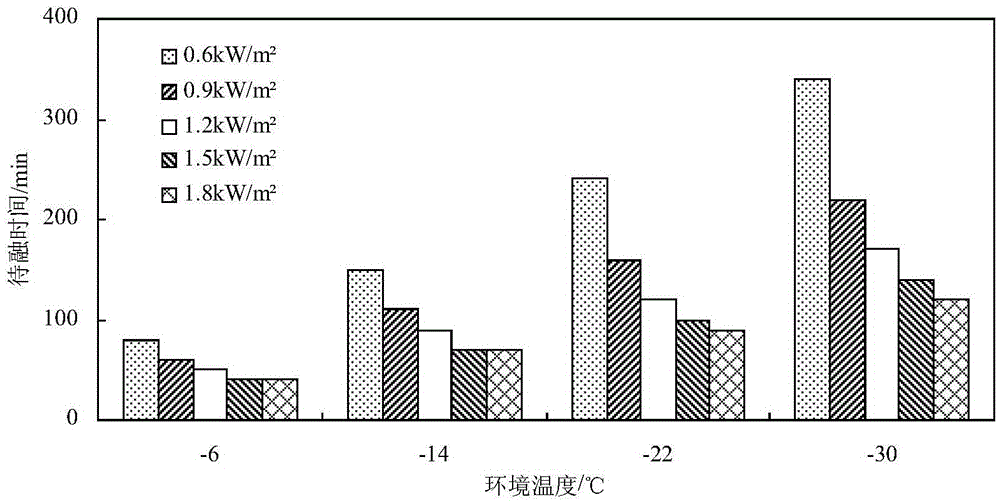

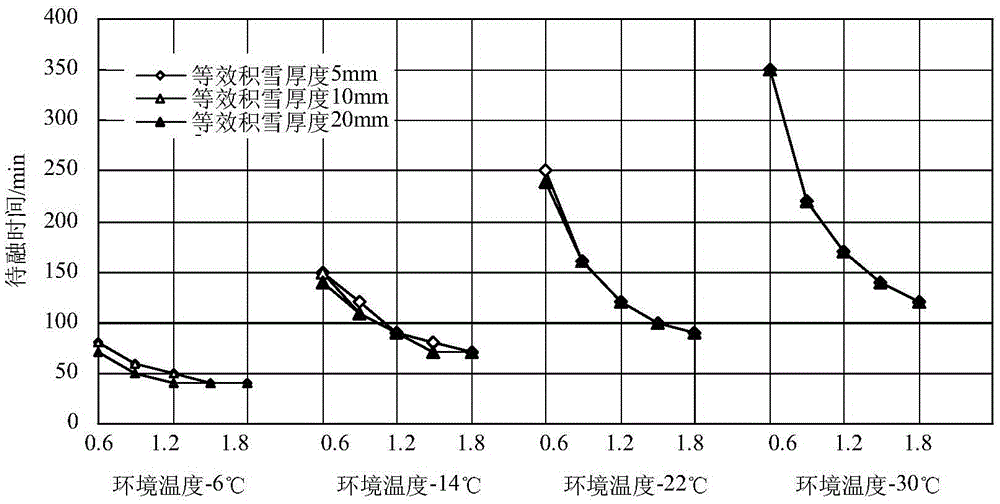

[0059] The difference from the first specific embodiment is that in the operation control method of the fluid heating road snow melting system in this embodiment, in the first step, the snow melting performance in the waiting stage is characterized by the waiting time to melt, wherein,

[0060] The stage to be melted refers to the stage from the moment when the fluid heating road snow melting system is started to the road surface temperature reaches freezing point; at the initial moment of the operation of the fluid heating road snow melting system, the heat generated by the fluid heating road snow melting system is mainly used to increase the road temperature; when the road surface temperature is low When the temperature is at the freezing point, the snow on the road surface is in a dry snow state. After the system has been running for a period of time, the temperature of some areas on the road surface reaches the freezing point, and the snow begins to melt at this time; accord...

specific Embodiment approach 3

[0064] The difference from Embodiment 1 or Embodiment 2 is that in the operation control method of the fluid heating road snow melting system in this embodiment, the average solid-liquid phase change heat flux in the snow melting stage is used to characterize the road surface snow melting ability in step 1, wherein,

[0065] The snowmelt stage refers to the stage when the snow at a certain point on the road surface starts to melt until the snow is completely melted; when some areas on the road surface just start to melt, the upper layer is dry snow and the lower layer is a mixture of snow and ice and snow; as the fluid heats the road The snow melting system continues to operate, and the upper snow gradually melts, forming a mixture of ice and snow, and with the continuous operation of the fluid heating road snow melting system, the melting is finally completed and water is formed; this stage is essentially a phase transition of snow from solid to liquid Therefore, the average s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com