Stirring-type highland barley yoghourt and preparation method thereof

A stirring type, highland barley acid technology, applied in the direction of milk preparations, bacteria used in food preparation, dairy products, etc., to achieve the effect of delicate taste, promote mineral absorption, and improve intestinal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

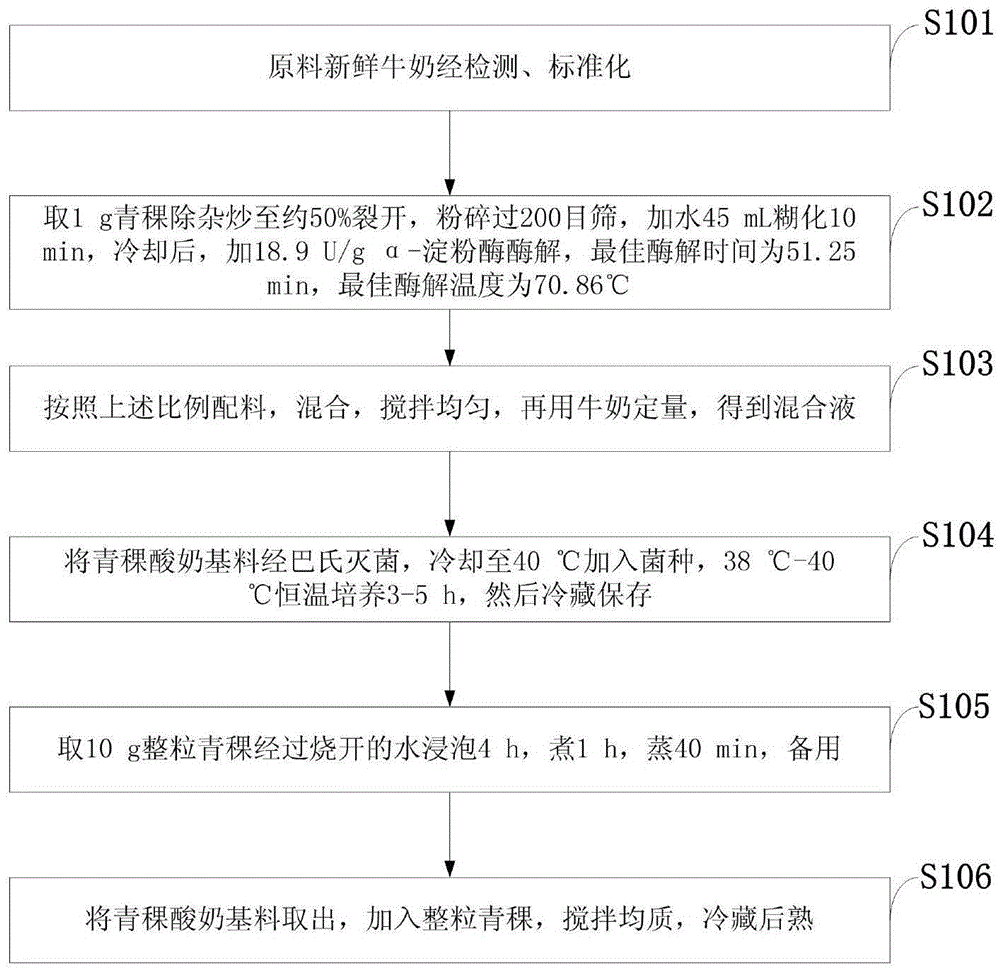

[0043] Such as figure 1 As shown, the method for preparing agitated highland barley yogurt according to the embodiment of the present invention includes the following steps:

[0044] S101: Raw fresh milk is tested and standardized;

[0045] S102: Take 1g of highland barley and stir-fry until about 50% cracked, crush it through a 200-mesh sieve, add 45mL of water to gelatinize for 10min, after cooling, add 18.9U / g α-amylase for enzymatic hydrolysis, the best enzymatic hydrolysis time is 51.25min, The best enzymolysis temperature is 70.86℃;

[0046] S103: Mix the ingredients according to the above ratio, mix them evenly, and then quantify the milk to obtain the mixed liquid;

[0047] S104: Pasteurize the highland barley yogurt base material, cool it to 40°C and add the strains, incubate at a constant temperature of 38°C-40°C for 3-5 hours, and then store in refrigeration;

[0048] S105: Take 10g of whole grain barley, soak it in boiling water for 4h, boil it for 1h, steam for 40min, and ...

Embodiment 1

[0052] The method for preparing agitated highland barley yogurt of the present invention has the following specific steps: clean the whole highland barley without impurities and stir-fry until about 50% of it is cracked, smash it through a 200-mesh sieve, add water to make a paste, and place it in a boiling water bath. Gelatinize for 10 minutes, add 14.5 U / g α-amylase after cooling, heat in a water bath at 78.8°C for 63.2 minutes, and then heat to inactivate the enzyme to prepare a highland barley enzymatic hydrolysate for use.

[0053] Mix the milk with 4wt% highland barley enzymatic hydrolysate, add 8wt% white sugar, pasteurize, cool to 40℃, add 4wt% strain and 0.15wt% stabilizer, culture and ferment at 40℃, put in after fermentation mature Store at 4-6°C and make a stirred barley yogurt base material for later use.

[0054] Take out the whole grain barley, soak it in boiling water for 4 hours, then boil it for 1 hour, and steam for 40 minutes to obtain the cooked whole grain bar...

Embodiment 2

[0057] The method for preparing agitated highland barley yogurt of the present invention has the following specific steps: clean the whole highland barley without impurities and stir-fry until about 50% of it is cracked, smash it through a 200-mesh sieve, add water to make a paste, and place it in a boiling water bath. Gelatinize for 10 minutes, add 14.5 U / g α-amylase after cooling, heat in a water bath at 78.8°C for 63.2 minutes, and then heat to inactivate the enzyme to prepare a highland barley enzymatic hydrolysate for use.

[0058] Mix the milk with 5wt% highland barley enzymatic hydrolysate, add 9wt% white sugar, pasteurize and cool to 40°C;

[0059] 6wt% strain and 0.15wt% stabilizer were added, cultured and fermented at 40°C, and stored at 4-6°C after fermentation matured to prepare a stirred barley yogurt base material for later use.

[0060] The whole grain barley is removed from impurities, soaked in boiling water for 4 hours, then boiled for 1 hour, and steamed for 40 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com