Astaxanthin composition, preparation and preparation method of composition

A technology of astaxanthin and composition, applied in the field of antioxidant chemicals, can solve problems such as easy oxidation, production process loss, intolerance to high temperature and high pressure, etc., and achieve good oil solubility and dispersibility, dispersibility and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

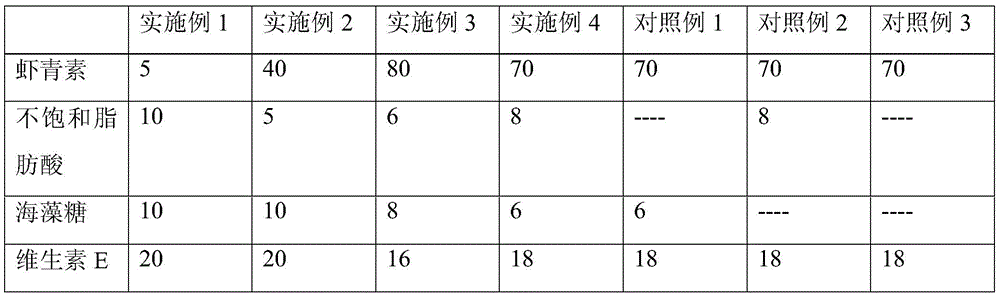

Examples

Embodiment 5

[0040] The preparation of embodiment 5 oily composition

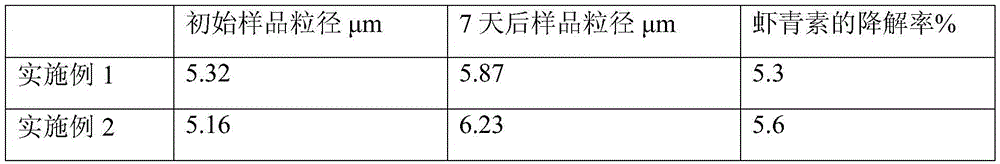

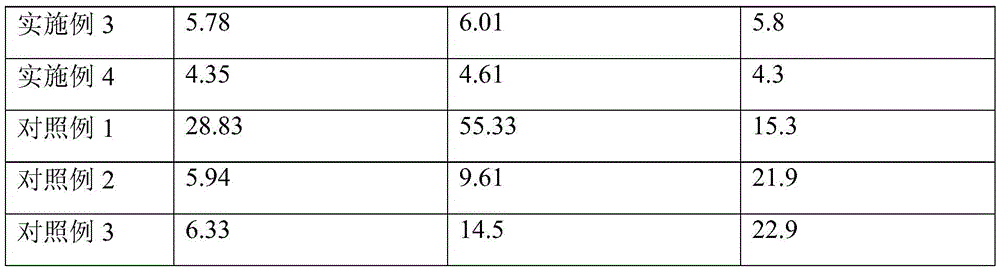

[0041] In this example, the astaxanthin compositions of the above-mentioned Examples 1-4 and Comparative Examples 1-3 are mainly used as basic raw materials, and then prepared into oily compositions. The preparation method is as follows: in parts by weight, add 15 parts of palm oil to 20 parts of the above-mentioned astaxanthin composition, mix well, and then grind 4 times in a ball mill with a pressure of 0.4 bar, and grind for about 10 minutes each time. 60g / min (grinding gap 0.05mm, 4180rpm, 470ml, filled with 0.2-0.4mm ZrO 2 ball), after grinding, add 45 parts by weight of palm oil and mix evenly, then measure the particle size of the oil.

[0042] Particle size was determined using a Malvern Mastersizer S at 22°C. The suspension of the astaxanthin derivative obtained by grinding was diluted to a concentration of 0.05% by weight using a grinding oil before measurement. The number recorded is the volume average pa...

Embodiment 6

[0048] The preparation of embodiment 6 emulsion

[0049] This embodiment mainly adopts the astaxanthin compositions of the above-mentioned Examples 1-4 and Comparative Examples 1-3 as basic raw materials, and then prepares an emulsified composition. The preparation method is as follows: in parts by weight, add 15 parts of polyglyceryl isostearate and 15 parts of cetyl ethylhexanoate to 10 parts of the above-mentioned astaxanthin composition, heat up to 55 ° C and mix evenly, as Oil phase; after mixing 50 parts of the oil phase and the water phase, use a homogenizer to mix and emulsify the oil phase into the water phase at 60°C, so that the particle size reaches 10.0 μm to 15.0 μm. Dilute the emulsified composition to 20 times with water, use Malvern Mastersizer S to measure the volume average particle size D[4,3] at 22°C; and use high-speed column chromatography to determine the content of astaxanthin.

[0050] In addition, for each emulsion, immediately after preparation and...

Embodiment 7

[0056] The preparation of embodiment 7 powdery composition

[0057] This embodiment mainly adopts the astaxanthin compositions of the above-mentioned Examples 1-4 and Comparative Examples 1-3 as basic raw materials, and then prepares an emulsified composition. The preparation method is as follows: in parts by weight, add 10 parts of the above-mentioned astaxanthin composition to 30 parts of ethanol, heat up to 35°C and mix evenly, then grind 4 times in a ball mill with a pressure of 0.4 bar, and grind for about 10 minutes each time , the flow rate is 60g / min (grinding gap 0.05mm, 4180rpm, 470ml, filled with 0.2-0.4mm ZrO 2 ball), after grinding, distill under reduced pressure until the volume is reduced by 1 / 3, and then spray dry to obtain a powder composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com