Preparation method of hydrogenation treatment catalyst

A hydrogenation treatment and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unsatisfactory mechanical strength of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

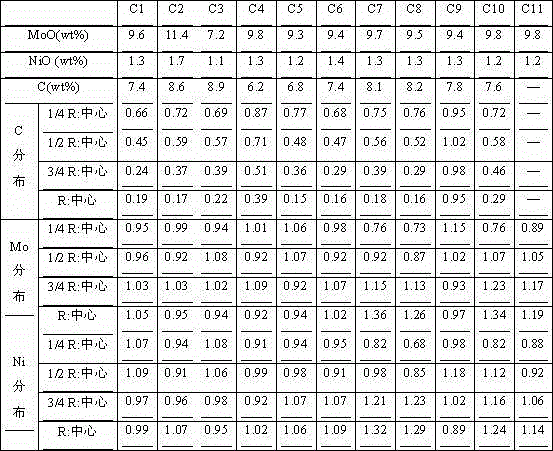

Examples

Embodiment 1

[0031] Weigh the pore volume as 0.9ml / g and the specific surface area as 220m 2 Put 100 grams of γ-phase cylindrical strip-shaped alumina carrier in a beaker, add 120ml of urea aqueous solution with a concentration of 25g / 100ml into the beaker and soak for 2 hours, filter off the excess solution, and dry the carrier at 110°C for 5 hours. Put the dried carrier into the spray rolling pot, and in the rotating state, spray and impregnate 25ml of xylitol aqueous solution with a mass concentration of 40% to the carrier in the rolling pot in a rotating state; then use a mass concentration of 20% Continue to spray and impregnate the alumina carrier with 40ml of xylitol aqueous solution; finally, continue to spray and impregnate the alumina carrier with 40ml of xylitol aqueous solution with a mass concentration of 10%. The excess solution was filtered off, the wet material was transferred into an autoclave and sealed at 120°C for 8 hours, and the treated material was dried at 120°C for...

Embodiment 2

[0033] Same as Example 1, except that the alumina carrier is a clover strip, and the concentration of urea is 30g / 100ml. When spraying and impregnating for the first time, use 30ml of an aqueous solution of sorbitol with a mass concentration of 30%. 50ml of an aqueous solution of 10% mass concentration of sorbitol, and 20ml of an aqueous solution of 5% mass concentration of sorbitol for the third spray dipping. During the first hydrothermal treatment, the temperature of the hydrothermal treatment was 130° C., and the treatment time was 10 hours. During the second hydrothermal treatment, the temperature of the hydrothermal treatment was 220° C., and the treatment time was 6 hours. MoO in active metal impregnation solution 3 The concentration is 12g / 100ml (the source of molybdenum is from ammonium molybdate), and the concentration of NiO is 1.8g / 100ml (the source of nickel is from nickel chloride). Catalyst C2 of the present invention is prepared. The properties of the catalyst ...

Embodiment 3

[0035] Same as Example 1, except that the concentration of urea is 20g / 100ml, four times of spray impregnation, 20ml mass concentration of 50% mannitol aqueous solution is used during the first spray impregnation, and 40ml of mannitol is used during the second spray impregnation. Aqueous solution of sorbitol with a mass concentration of 30%, use 20ml of an aqueous solution of sorbitol with a mass concentration of 20% for the third spray and immersion, and use 20ml of an aqueous solution of sorbitol with a mass concentration of 10% for the fourth spray and immersion . During the first hydrothermal treatment, the temperature of the hydrothermal treatment was 110° C., and the treatment time was 12 hours. During the second hydrothermal treatment, the temperature of the hydrothermal treatment was 200° C., and the treatment time was 10 hours. MoO in active metal impregnation solution 3 The concentration is 8g / 100ml (the source of molybdenum is from ammonium molybdate), the concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com