A processing method for precision large-size rigid pipe components

A processing technology and large-size technology, applied in the field of precision large-size rigid tube component processing technology, can solve problems such as poor manufacturability, large size, unqualified component shape and position accuracy, etc., to achieve reasonable process routes and reduce processing costs , The effect of solving processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

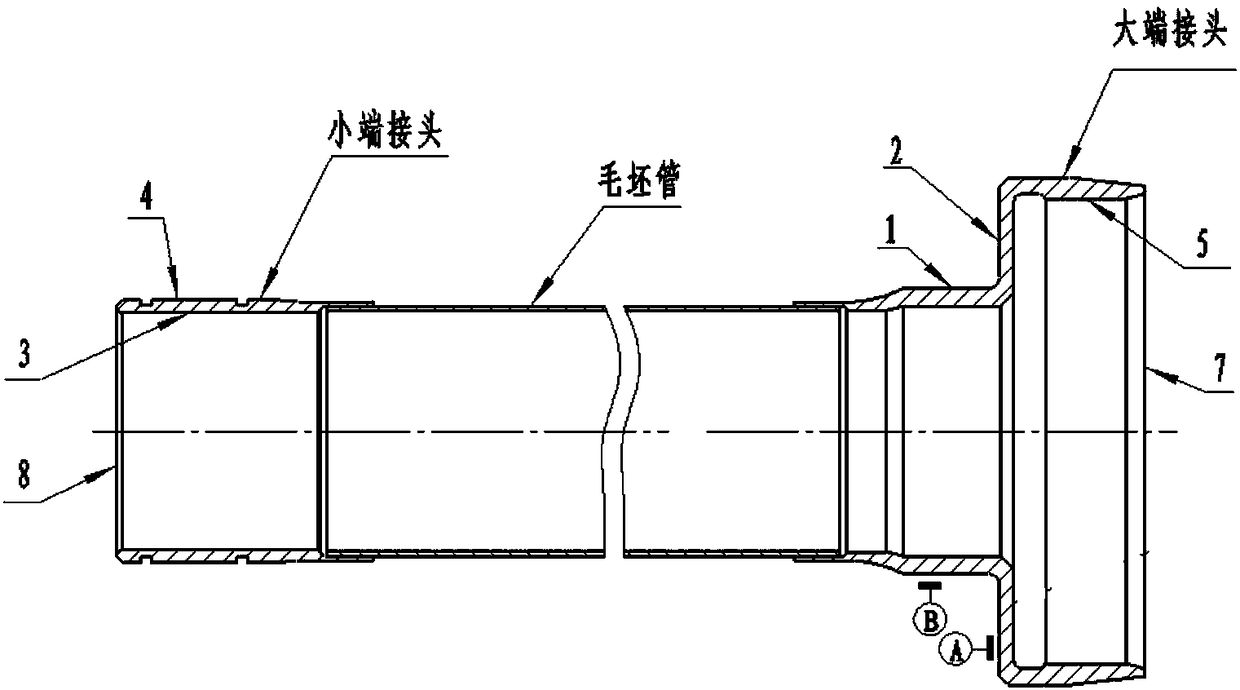

[0044] This embodiment provides a processing method for a precision large-size rigid pipe assembly, which is characterized in that: in the processing method for a precision large-size rigid pipe assembly, the large-end joint leaves a combined machining allowance and performs finishing on the assembly; In order to avoid the problem of out-of-axis joint outer circles at both ends caused by welding deformation, the positioning datums 1, 2 and 4 used on the horizontal jig boring machine are processed at one time on the ordinary lathe after welding, see figure 1 , eliminate the positioning and clamping deformation on the horizontal jig boring machine; then bore the inner holes at both ends on the horizontal jig boring machine, that is, align the small end carburizing inner hole 3, bore the big end big inner hole 5, and the big end outer end face 7 and the small end face 8, as the finishing benchmark of the follow-up process;

[0045] The processing route is:

[0046] Pipe material...

Embodiment 2

[0076] This embodiment provides a processing method for a precision large-size rigid pipe assembly, which is characterized in that: in the processing method for a precision large-size rigid pipe assembly, the large-end joint leaves a combined machining allowance and performs finishing on the assembly; In order to avoid the problem of out-of-axis joint outer circles at both ends caused by welding deformation, the positioning datums 1, 2 and 4 used on the horizontal jig boring machine are processed at one time on the ordinary lathe after welding, see figure 1 , eliminate the positioning and clamping deformation on the horizontal jig boring machine; then bore the inner holes at both ends on the horizontal jig boring machine, that is, align the small end carburizing inner hole 3, bore the big end big inner hole 5, and the big end outer end face 7 and the small end face 8, as the finishing benchmark of the follow-up process;

[0077] The processing route is:

[0078] Pipe material...

Embodiment 3

[0108] This embodiment provides a processing method for a precision large-size rigid pipe assembly, which is characterized in that: in the processing method for a precision large-size rigid pipe assembly, the large-end joint leaves a combined machining allowance and performs finishing on the assembly; In order to avoid the problem of out-of-axis joint outer circles at both ends caused by welding deformation, the positioning datums 1, 2 and 4 used on the horizontal jig boring machine are processed at one time on the ordinary lathe after welding, see figure 1 , eliminate the positioning and clamping deformation on the horizontal jig boring machine; then bore the inner holes at both ends on the horizontal jig boring machine, that is, align the small end carburizing inner hole 3, bore the big end big inner hole 5, and the big end outer end face 7 and the small end face 8, as the finishing benchmark of the follow-up process;

[0109] The processing route is:

[0110] Pipe material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com