Carbon-emission-free marine oil gas energy production method and device

A production method and carbon emission technology, which is applied in the fields of clean energy and marine engineering, can solve the problems of increasing the difficulty of preventing sulfur corrosion, oil well scrapping, high cost, etc., and achieve the effect of economical and safe sulfur corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

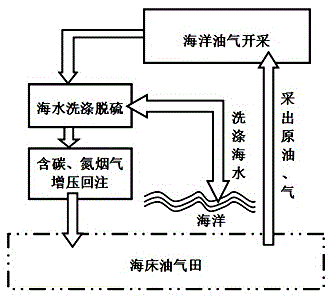

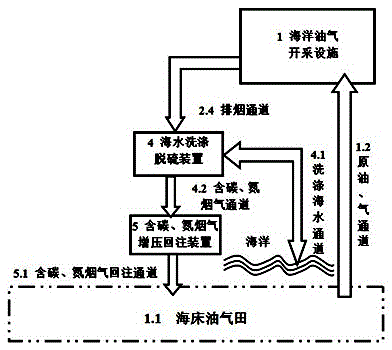

[0035] Embodiment 1: It is the basic embodiment of the production method of the carbon-free marine oil and gas energy of the present invention. as attached figure 1 , 5 The production method of the carbon-free marine oil and gas energy shown, the steps include: offshore oil and gas exploitation, washing and desulfurizing the flue gas produced by the offshore oil and gas energy production equipment including offshore oil and gas exploitation, and desulfurizing the carbon and nitrogen fumes after desulfurization The gas is reinjected into the seabed oil and gas field; the carbon-containing and nitrogen-containing flue gas is a mixed gas containing carbon dioxide, or carbon dioxide and nitrogen; The gas is pressurized and injected back into the seabed oil and gas field 1.1 to store carbon dioxide and enhance oil and gas recovery. The offshore oil and gas energy production equipment is an offshore oil and gas exploitation facility 1 .

Embodiment 2

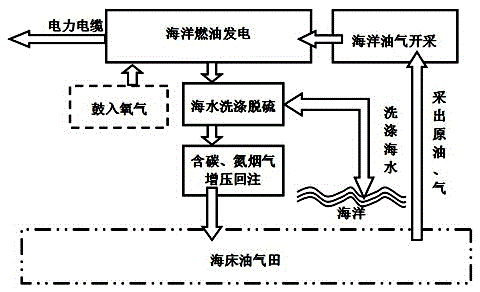

[0036] Embodiment 2: is a further embodiment on the basis of Embodiment 1. as attached figure 2 , 5 The carbon-emission-free marine oil and gas energy production method of the present invention shown in the present invention also includes the steps of using oil and gas to generate electricity from marine fuel oil and externally transmitting electric energy; the marine oil and gas energy production equipment used for marine fuel oil power generation is built near the offshore oil and gas exploitation facilities. Marine oil-fired power plants using oil and gas2.

[0037] The technical scheme, principle, effect of above-mentioned method embodiment 1,2 are further explained as follows:

[0038] The reinjection of nitrogen and carbon dioxide gas into oil and gas fields is called "nitrogen flooding" or "CO2 flooding" respectively. 2 Flooding" or "Nitrogen and CO 2 “Hybrid Flooding” oil and gas augmentation process. The flue gas produced by oil and gas extraction facilities, mar...

Embodiment 3

[0044] Embodiment 3: it is a further embodiment on the basis of embodiment 2, as attached figure 2 , 4 As shown, in the production method of the carbon-free marine oil and gas energy, the oil and gas-burning marine oil-gas power plant 2 burns oil and gas in the form of oxygen-enriched combustion to increase the carbon dioxide content and reduce the nitrogen content. In the case of blowing oxygen into the combustion device of the marine oil-fired power plant 2, the concentration of carbon dioxide in the generated flue gas can exceed 90%, which is conducive to increasing the amount of carbon dioxide sequestered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com