High-pressure water injection well head pressure gauge connector and matched wrench thereof

A technology of wellhead pressure and water injection well, which is applied in the directions of wrenches, wellbore/well components, and production fluids, etc., can solve the problems of high water injection pressure, leakage, leakage, and high water injection pressure of needle valves, so as to improve venting efficiency and economic cost. Low and good pressure transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

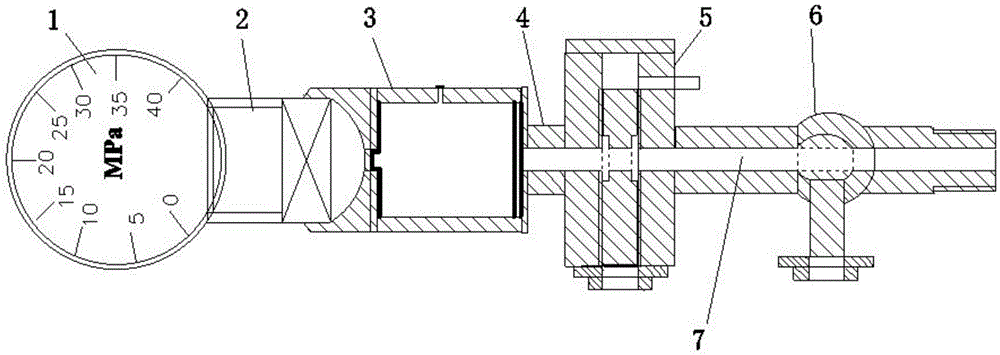

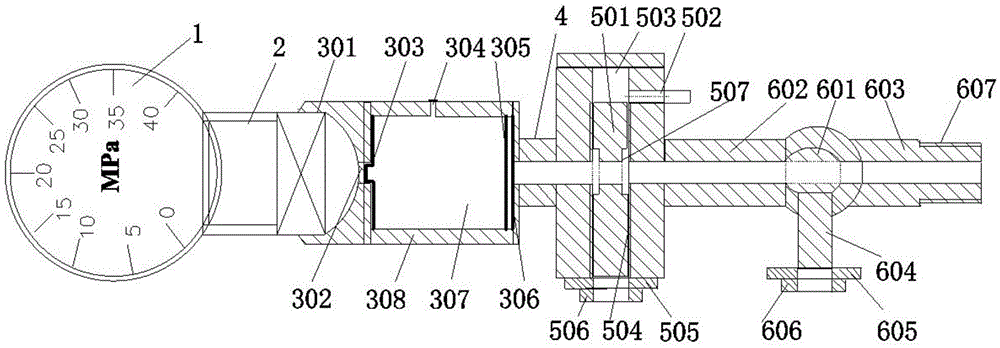

[0027] Such as Figure 1~4 As shown, a wellhead pressure gauge connector of a high-pressure water injection well includes a pressure gauge 1, a pressure gauge joint 2, a sensing component 3, a connecting neck 4, a venting component 5, and a ball valve component 6; the pressure gauge 1 is installed on the pressure gauge joint 2 Above, the pressure gauge connector 2 is connected to the sensor assembly 3 through the thread provided on the upper end of the sensor assembly 3; the connection neck 4, the vent assembly 5, and the hollow part of the ball valve assembly 6 form a liquid passage 7.

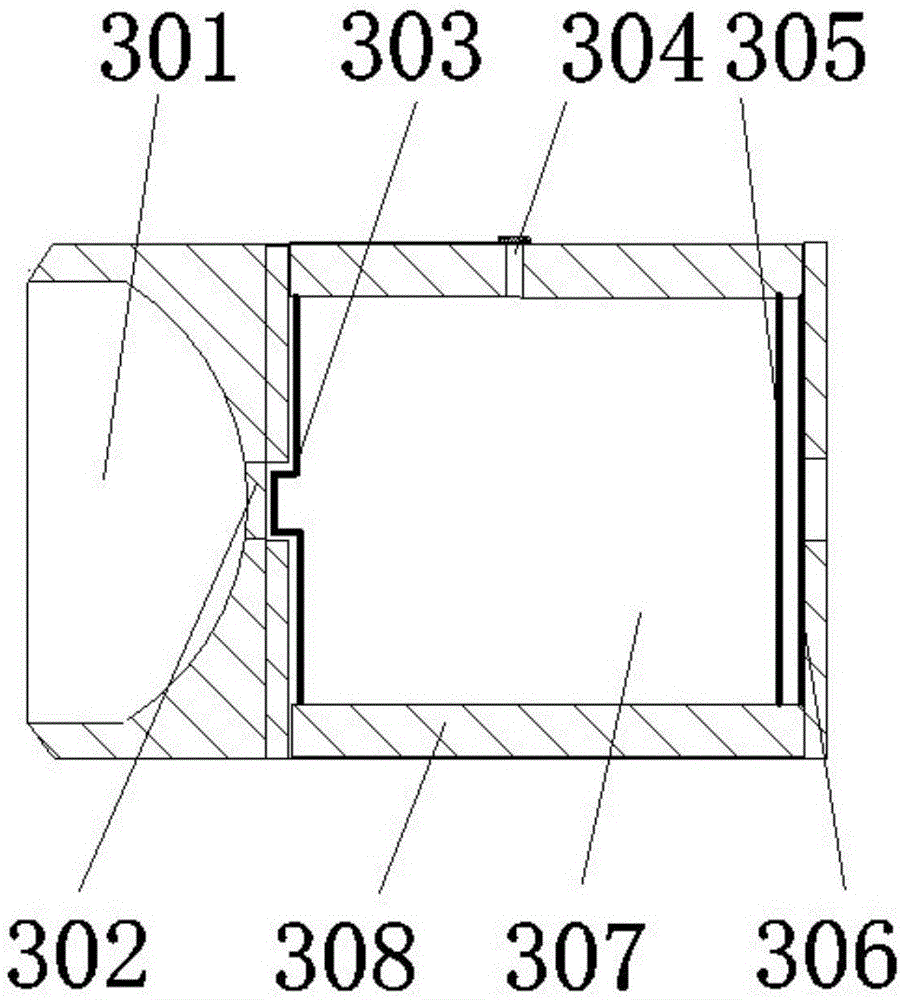

[0028] Such as image 3 As shown, the sensing assembly 3 includes a pressure gauge sensor 301, a pressure sensor 302, a pressure sensing diaphragm 1 303, an antifreeze oil addition port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com