Crude oil condensation point measurement device based on ultrasonic technology and measurement method adopting crude oil condensation point measurement device

An ultrasonic technology, a technology of measuring devices, applied in measuring devices, materials analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problem that it is not easy to observe whether the sample is solidified, cannot accurately control the pouring amount, and increase the error of measurement results. and other problems, to achieve the effect of simple and convenient measurement process, compact structure and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

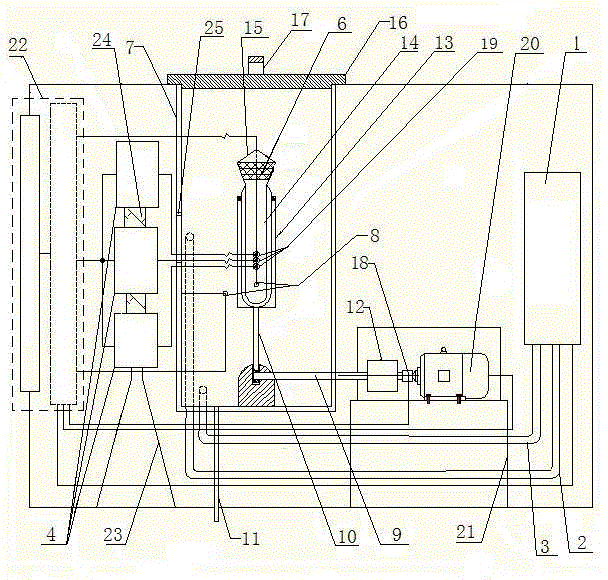

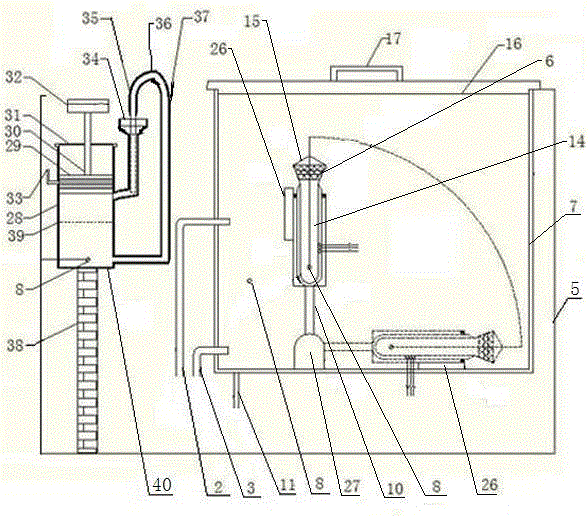

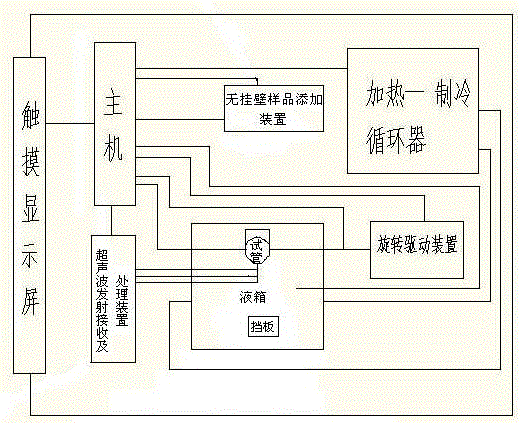

[0032] Below in conjunction with accompanying drawing, the present invention will be further described:

[0033] Such as figure 1 As shown, this novel crude oil freezing point measuring device includes three identical ultrasonic transmitting-receiving and processing devices 4, three identical ultrasonic single probes 19, a box body 5, a liquid tank 7, a shockproof and noise-isolated box 21, and a freezing point Test tube 14, freezing point test tube tank 13, sample adding device without wall, rotating drive device, heating-cooling liquid circulator 1, terminal control system 22 (ultrasonic control module, temperature processing module, motor control module are installed in the terminal control system 22 Module, circulator control module, electric heating belt temperature control module and other application modules), including liquid tank 7, ultrasonic emission-receiving and processing device 4, terminal control system 22, shockproof and noise-isolated box 21, rotary drive dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com