Refractory product with a SiAiON matrix

A product, refractory technology, applied in ceramic or metal powder cooking support, manufacturing metallurgical furnace coating, manufacturing other fields, can solve the problem of insufficient heat cycle resistance, to achieve improved compression strength and heat cycle resistance, excellent durability The effect of thermal cycling

Active Publication Date: 2016-05-18

圣戈班研究中心与欧洲研究院

View PDF17 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, their thermomechanical strength, especially their resistance to thermal cycling is still insufficient in the harshest environments

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

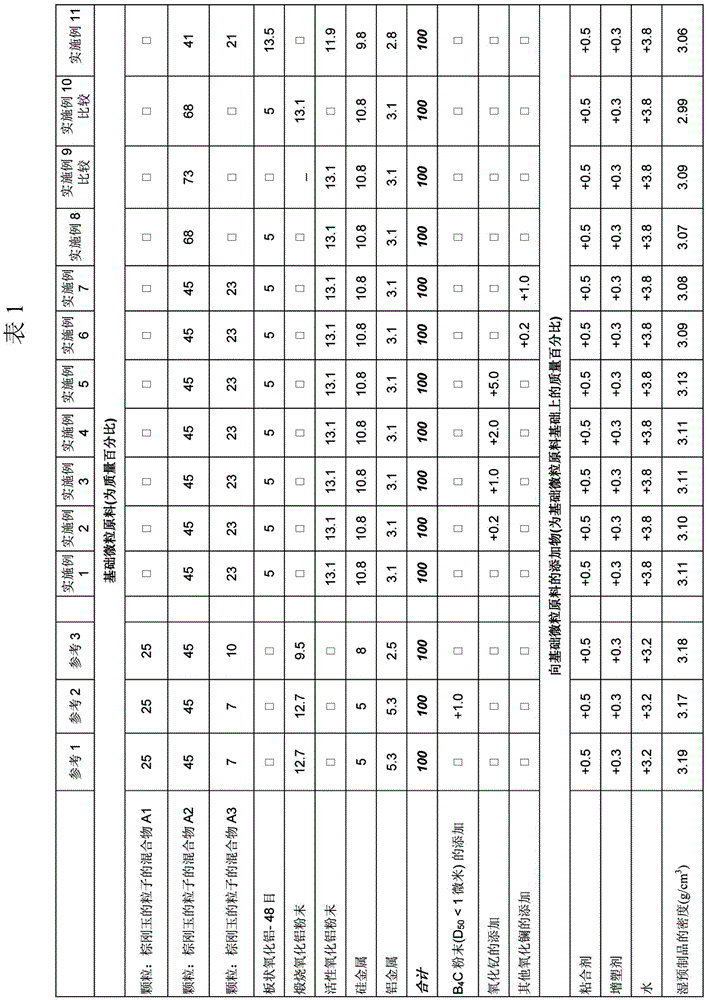

[0281] A comparison of Example 11 with respect to Example 1 shows that despite an acceptable combination of corrosion resistance in tests A+B+C, the oxidation resistance deteriorates when the amount of platy alumina in the mixture is increased too much .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

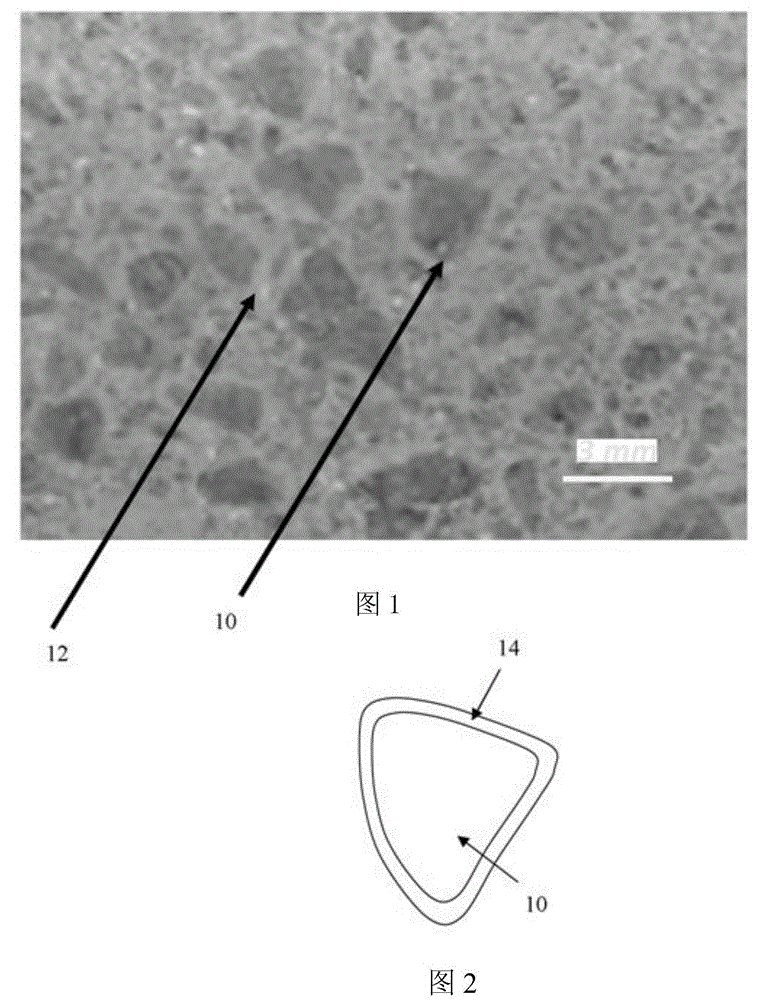

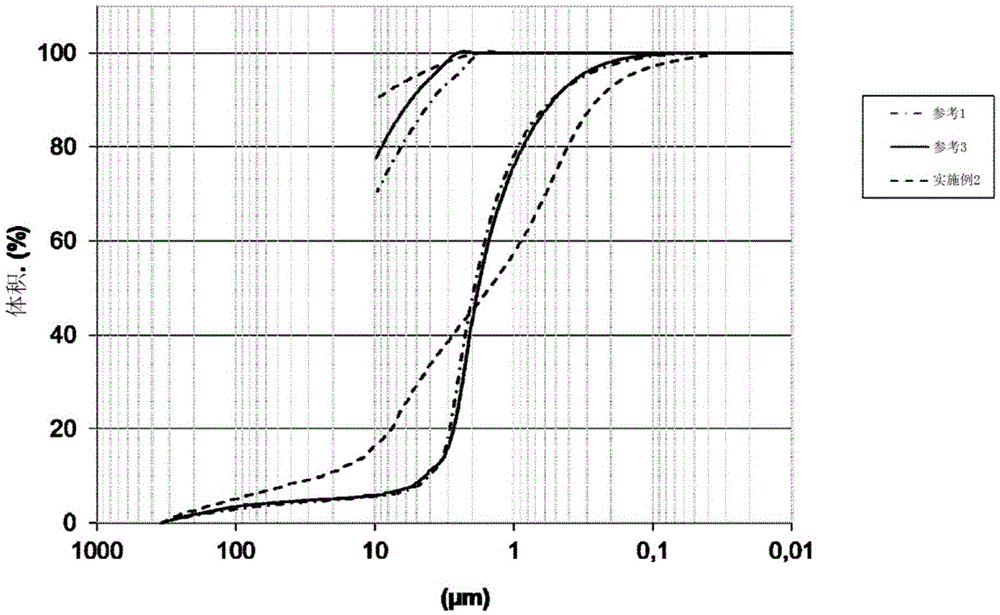

A sintered refractory product consisting of: a granulate consisting of all the particles having a size larger than 100 [mu]m, or "grains", the granulate representing between 55% and 85% by mass of the product, the maximum size of the grains being smaller than 3.5 mm, and a matrix binding said grains and consisting of the particles having a size smaller than or equal to 100 [mu]m, or "fine particles", said matrix comprising at least one crystallised SiAlON phase of formula SixAlyOuNv, in which x is greater than or equal to 0, greater than 0.05, greater than 0.1 or greater than 0.2, and less than or equal to 1, less than or equal to 0.8 or less than or equal to 0.4; y is greater than 0, or greater than 0.1, greater than 0.3 or greater than 0.5, and less than or equal to 1; u is greater than or equal to 0, greater than 0.1 or greater than 0.2, and less than or equal to 1 or less than or equal to 0.7; v is greater than 0, greater than 0.1, greater than 0.2 or greater than 0.5, or greater than 0.7, and less than or equal to 1; at least one of stoichiometric indices x, y, u and v being equal to 1, the volume of the fraction of the pores having a size of between 10 and 100 microns being greater than 4% of the total volume of pores.

Description

technical field [0001] The present invention relates to a refractory sintered product, in particular in block form, and to a method for its manufacture. The invention also relates to the use of this product or block for the manufacture of metallurgical furnace coatings, in particular for the coating of crucibles or slots or tuyeres of blast furnaces, or even other furnace refractory coatings, heat exchangers Refractory coatings or cooking supports, more particularly ceramic or metal powder cooking supports. Background technique [0002] Composite refractory products are known which comprise refractory particles linked by a binder matrix of the SiAlON type. Such products are known in particular from US4,533,646, US3,991,166, US4,243,621 or EP0153000. These products are resistant to steam oxidation and alkaline attack, but have poor corrosion resistance. [0003] EP0482984 discloses a refractory product comprising 6-z al z o z N 8-z Refractory particles connected by a m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/597C04B35/581C04B35/584C04B35/101C04B35/103C04B35/66

CPCC04B35/101C04B35/1015C04B35/103C04B35/66C04B2235/3222C04B2235/3225C04B2235/3227C04B2235/3821C04B2235/383C04B2235/3865C04B2235/3869C04B2235/402C04B2235/428C04B2235/5427C04B2235/5445C04B2235/5472C04B2235/604C04B2235/608C04B2235/6567C04B2235/658C04B2235/72C04B2235/728C04B2235/764C04B2235/77C04B2235/80C04B2235/9669C04B35/597C04B35/622F27D1/1684C04B2235/3873C04B2235/42F27D2001/1689

Inventor 纳吉·布马迪弗雷德里克·鲁莱

Owner 圣戈班研究中心与欧洲研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com