Patents

Literature

47 results about "Matrix bound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

IGG separation medium

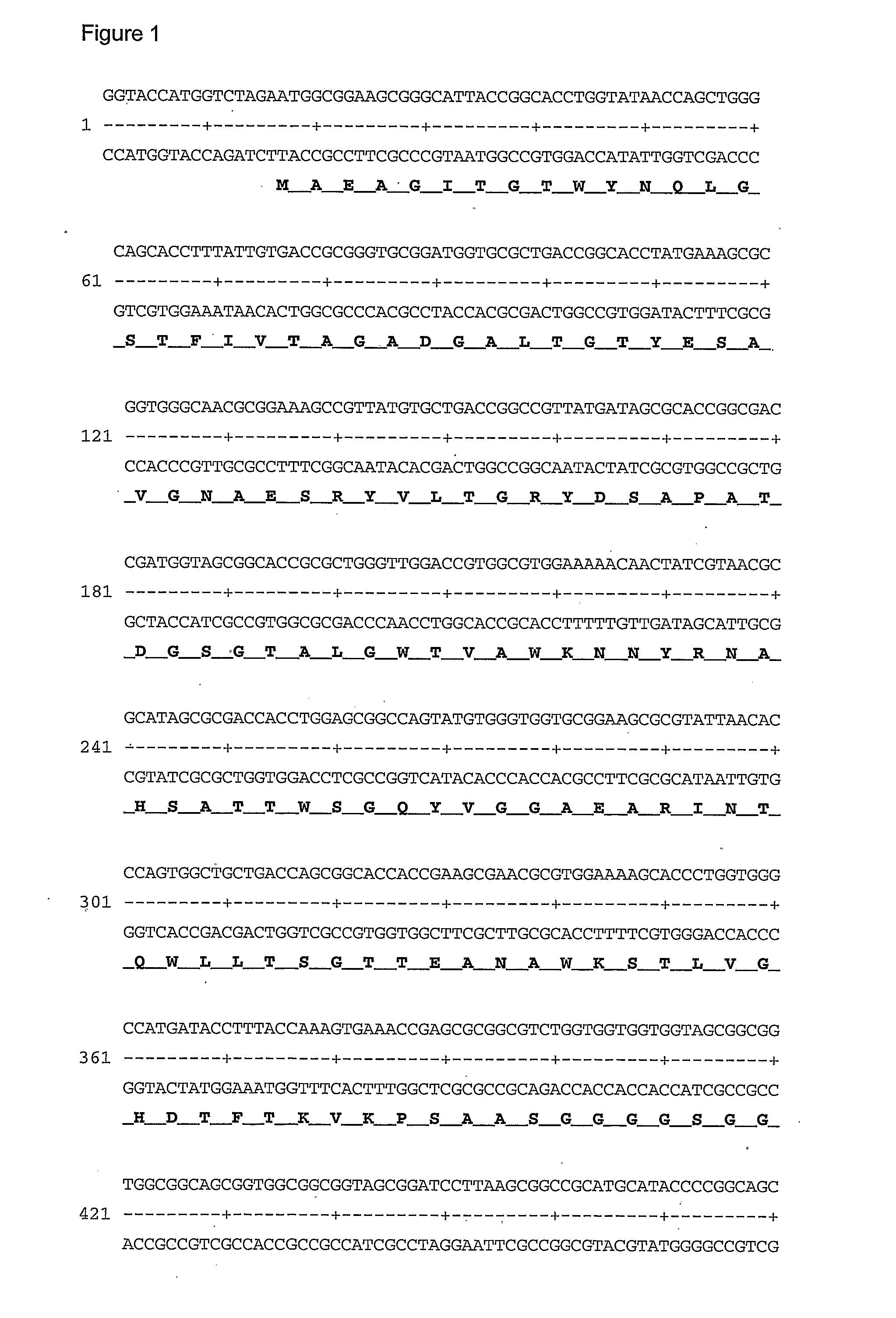

A separation medium having a base matrix and matrix-bound groups which exhibit recombinant Protein A containing a cysteine. The groups are of formula:where B is a bridge which binds to the base matrix and X includes a heteroatom N or S from rProtein A-cys. In a preferred embodiment X is a thioether sulphur and / or a secondary amine (-NH-). An alternative embodiment features a variant of Protein A in which the C-terminal residue is cysteine.

Owner:GE HEALTHCARE BIOPROCESS R&D

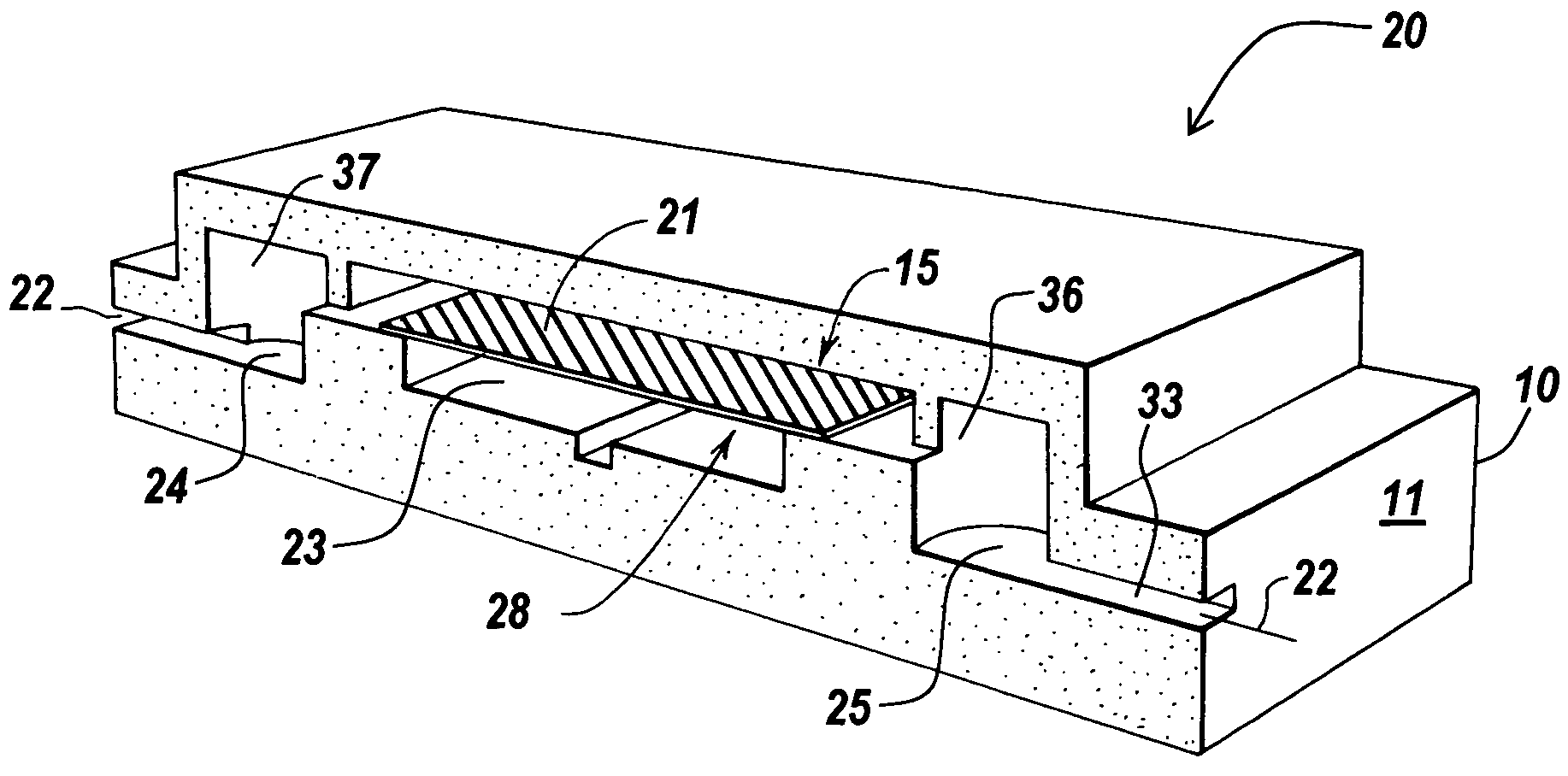

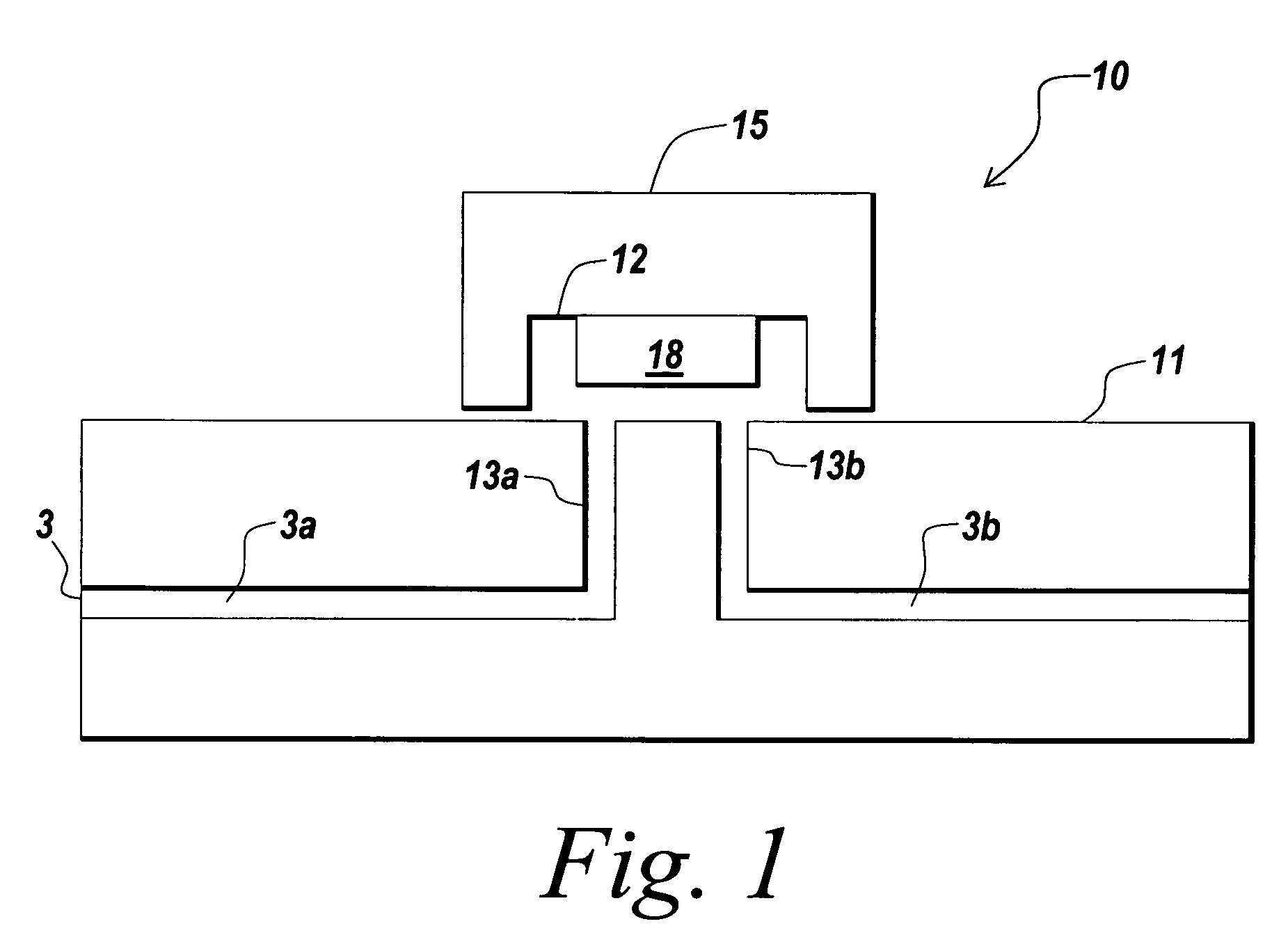

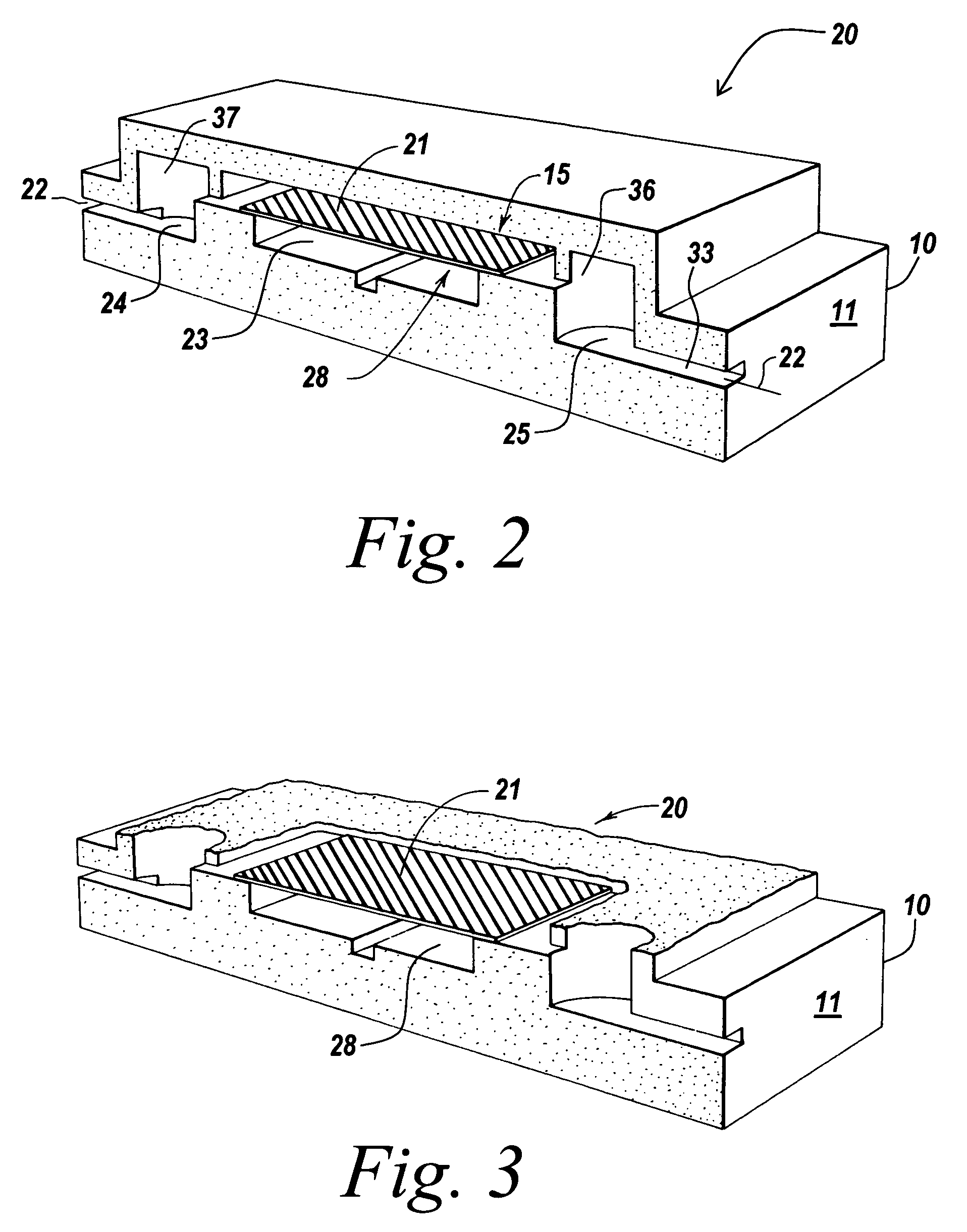

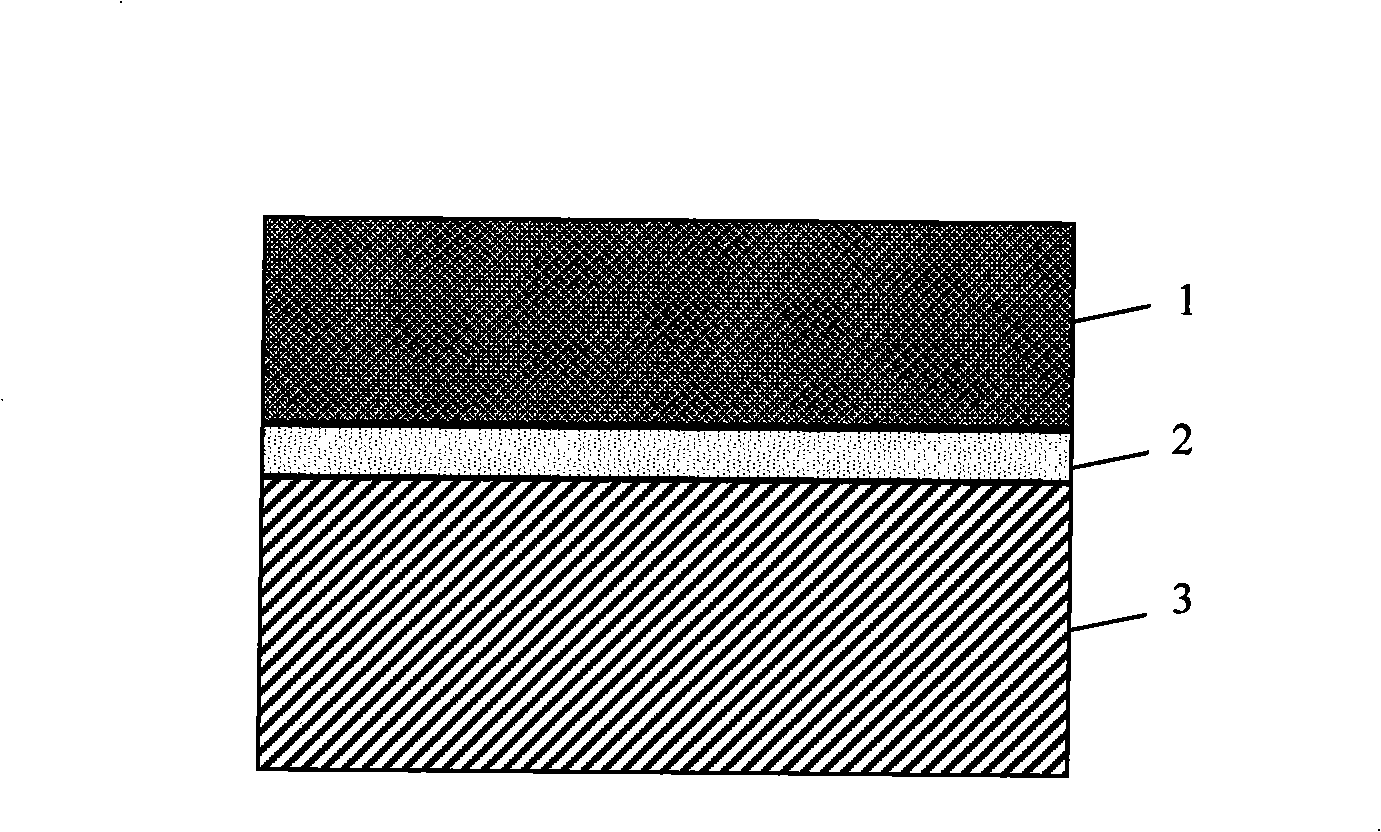

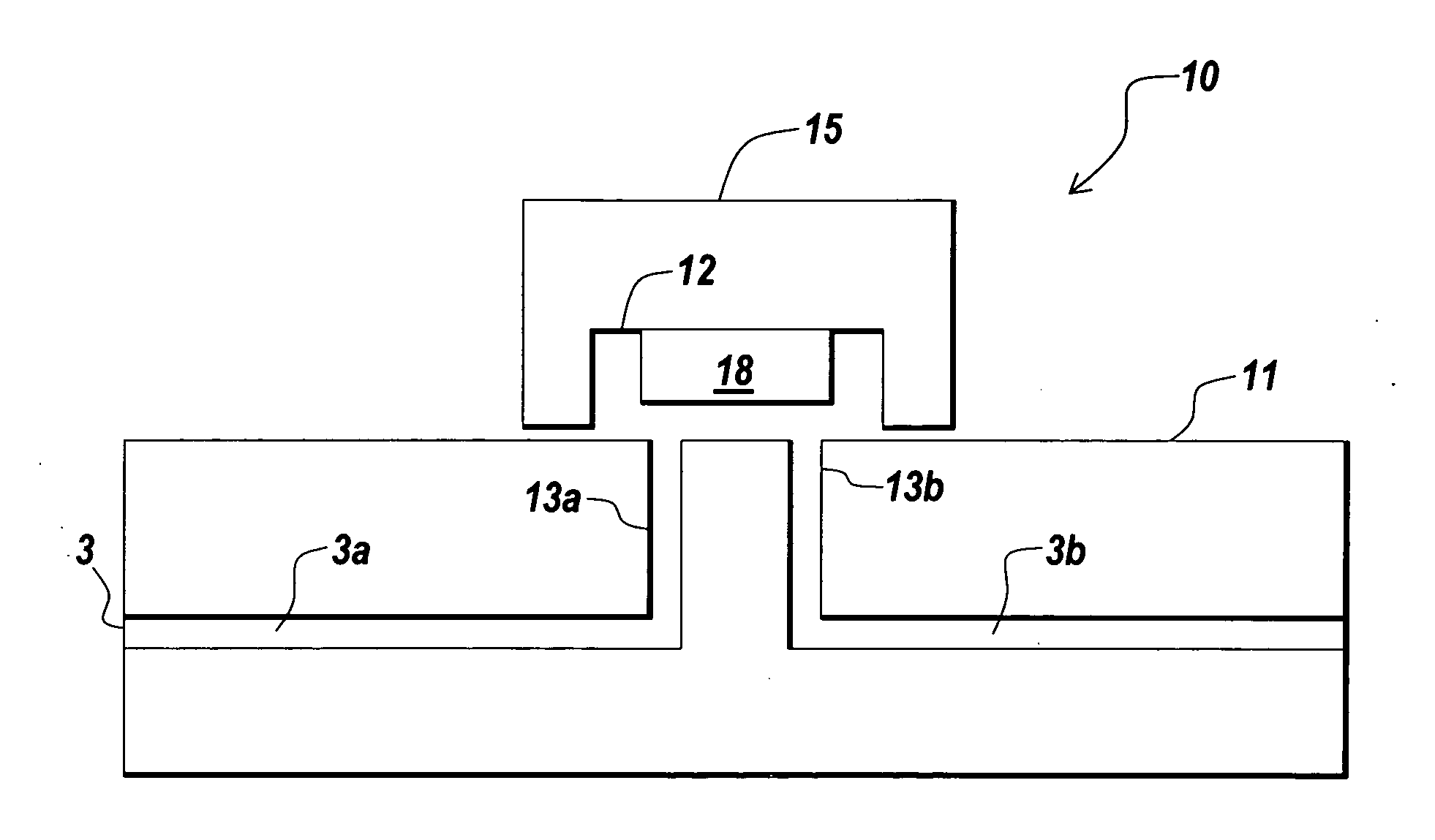

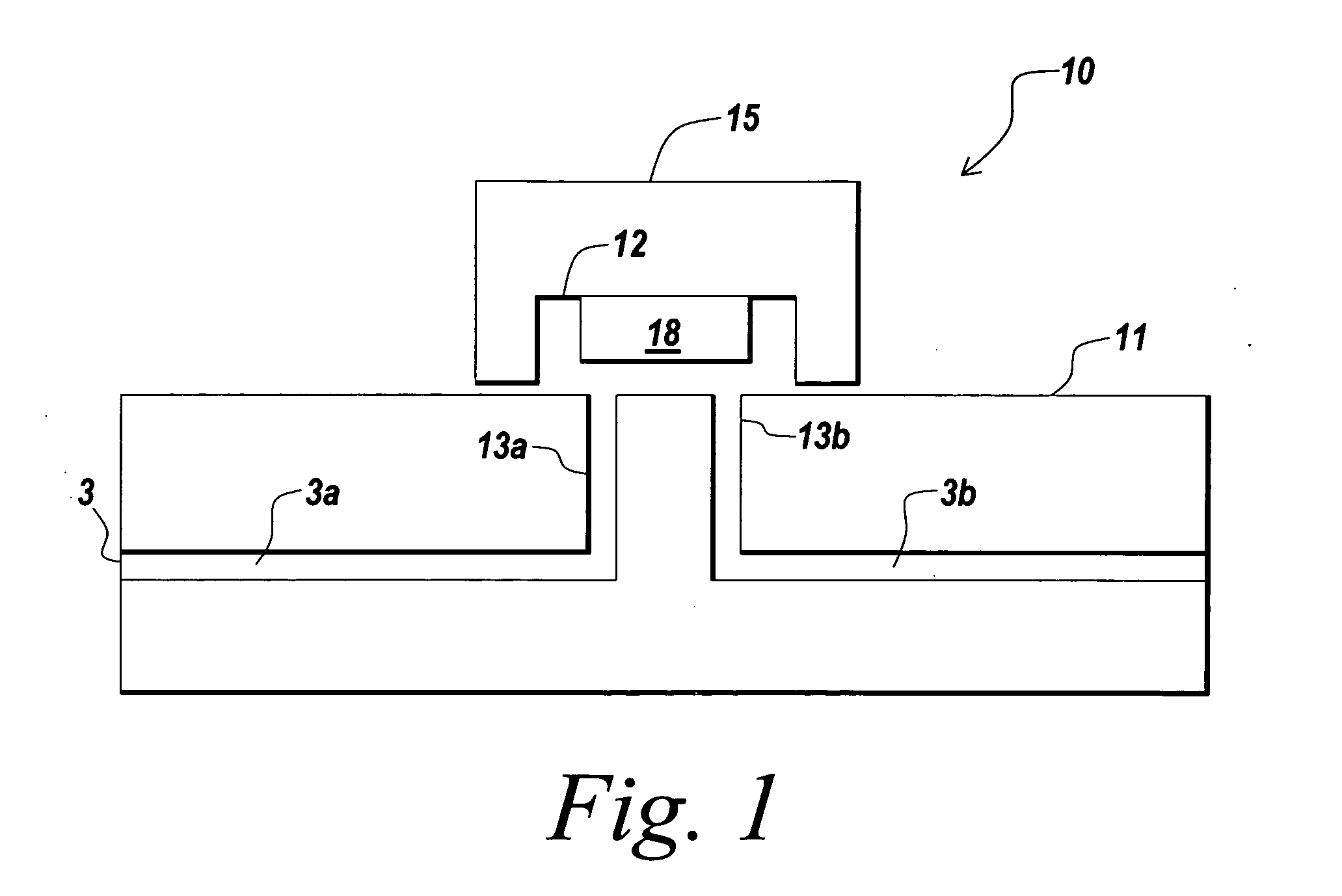

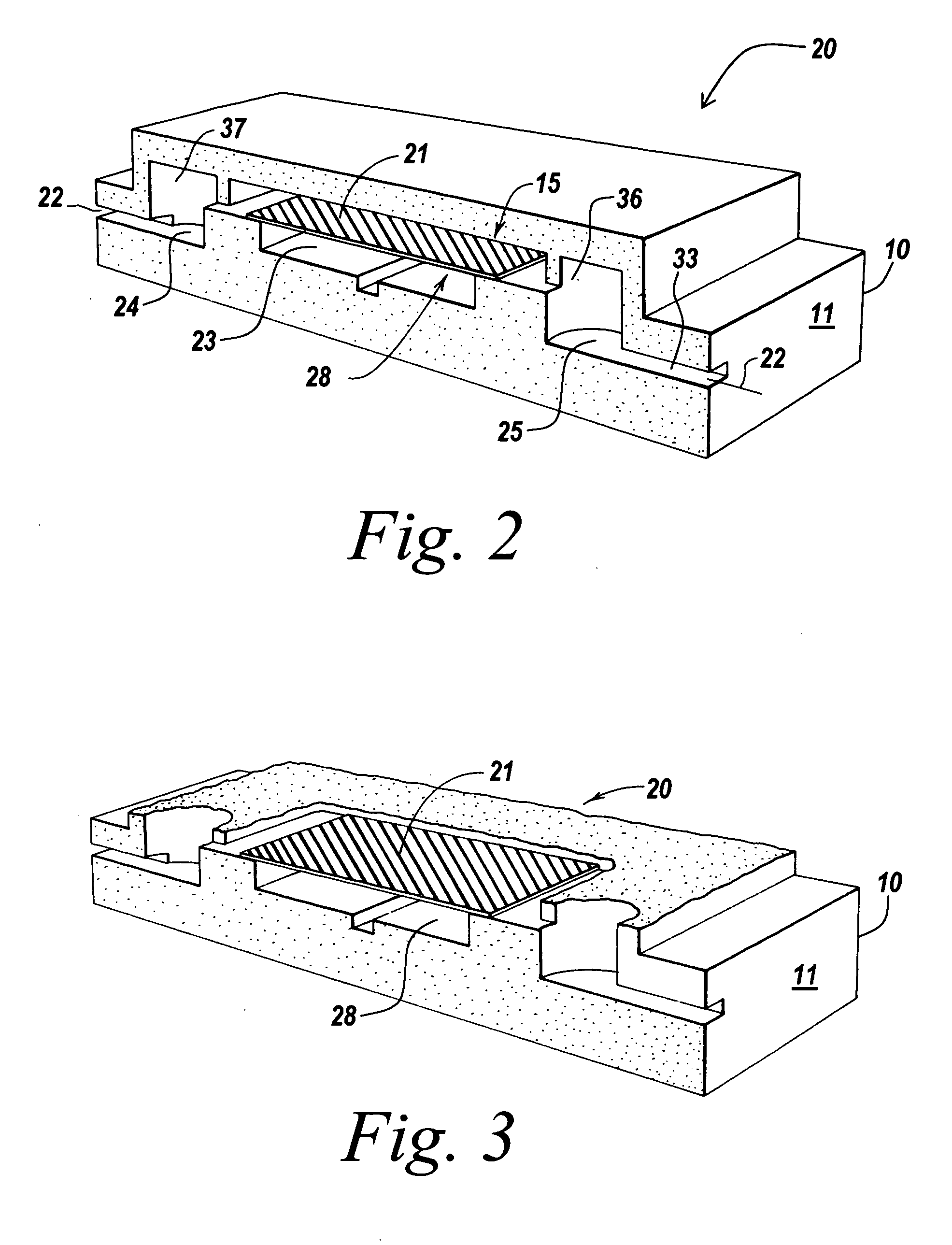

Implementation of microfluidic components, including molecular fractionation devices, in a microfluidic system

A system and method for integrating microfluidic components in a microfluidic system enables the microfluidic system to perform a selected microfluidic function. A capping module includes a microfluidic element for performing a microfluidic function. The capping module is stacked on a microfluidic substrate having microfluidic plumbing to incorporate the microfluidic function into the system. The microfluidic element may comprise a matrix having an affinity for selected molecules in a sample. The matrix binds, reacts with and / or retains the selected molecules without affecting other molecules in the sample.

Owner:CYTONOMEST

Cemented carbide cutting tool for multi-component coating

ActiveCN101407905AHigh coating hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingAlloyHigh intensity

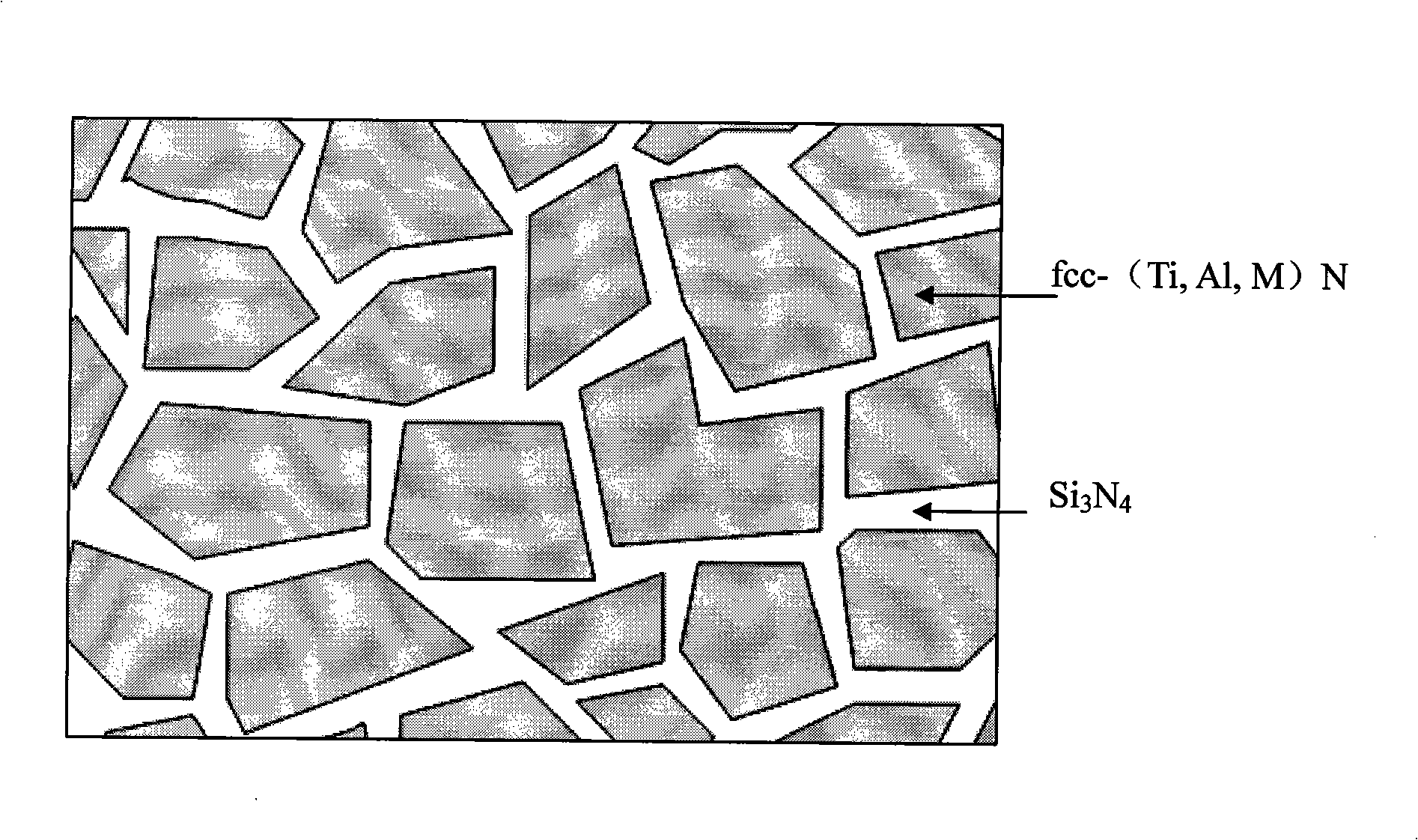

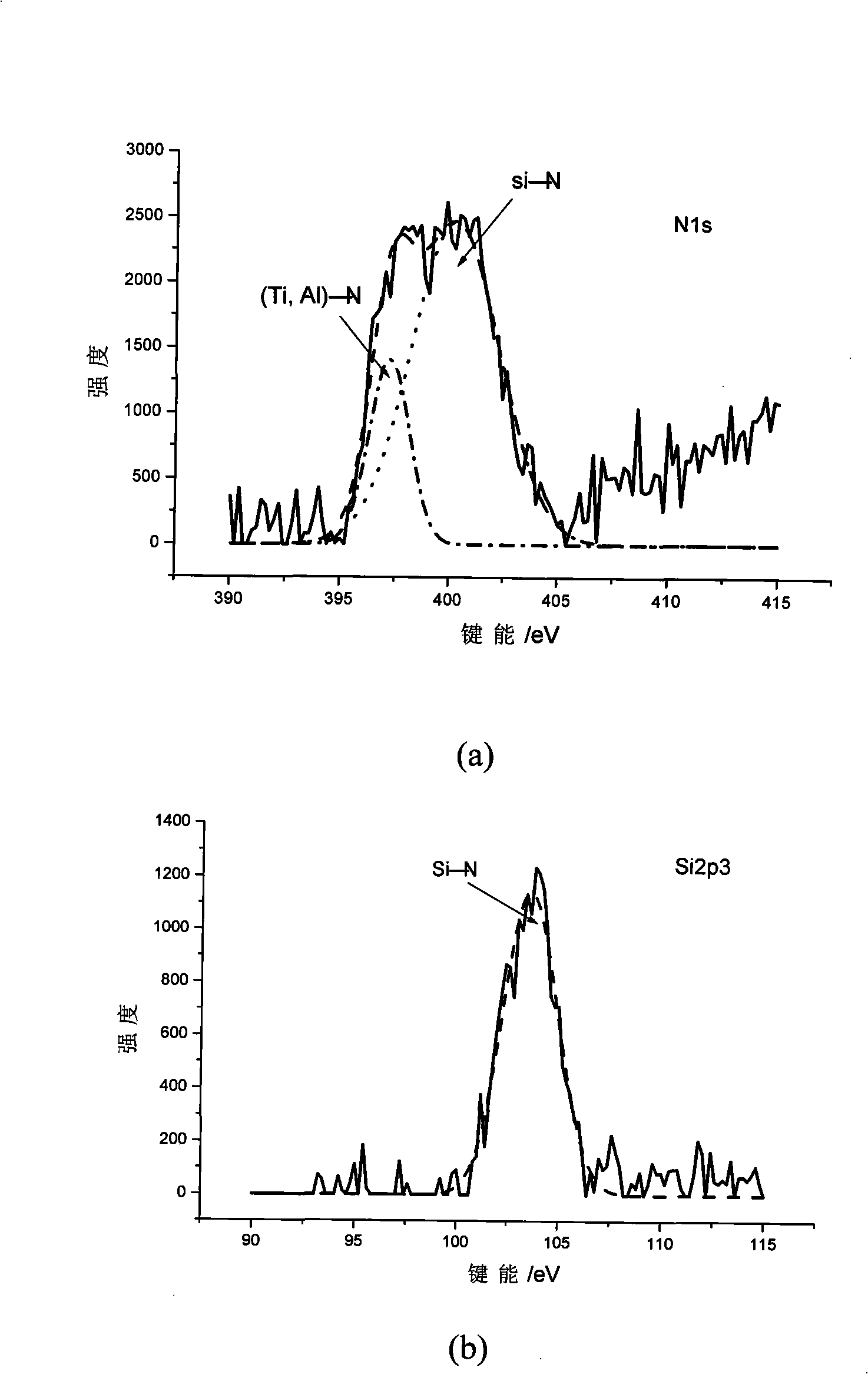

The invention discloses a cemented carbide cutting tool of a multi-component coating, which comprises a matrix and a coating coated on the matrix by a PVD method; wherein, the coating comprises a matrix binding layer coated on the matrix and a composite mixed crystal structural layer which is coated on the matrix binding layer and contains nano crystalline / amorphous composition; the matrix binding layer comprises at least a Ti-based metal layer which comprises at least one of metal elements of Al, Si and groups of IVB, VB and VIB; the composite mixed crystal structural layer comprises elements of Ti1-a-b-cAlaMbSicN, wherein M is one or a plurality of metal elements of Ta, Nb, Zr, Cr, Hf and W. The cemented carbide cutting tool has the advantages of high wearing resistance, high intensity, high temperature resistance, impact resistance, good binding of the coating and matrix, etc.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Vitreous bond compositions for abrasive articles

Bonded abrasive articles are described wherein a metal boride modified, lead-free vitreous matrix binds abrasive grains, such abrasive articles demonstrate improved performance over vitreous bonded abrasive articles with known vitreous matrices. Vitreous bond precursor materials are described including admixtures comprising lead-free vitreous precursor material and powder of metal boride(s), and admixtures comprising metal boride modified, lead-free vitreous particles. Methods are described for producing vitreous bonded abrasive articles having abrasive grains bound by metal boride modified, lead-free vitreous matrices.

Owner:VALENITE U S A INC +2

Catalyst for low-temperature catalytic combustion of volatile aromatic hydrocarbon organic matters and method for preparing catalyst

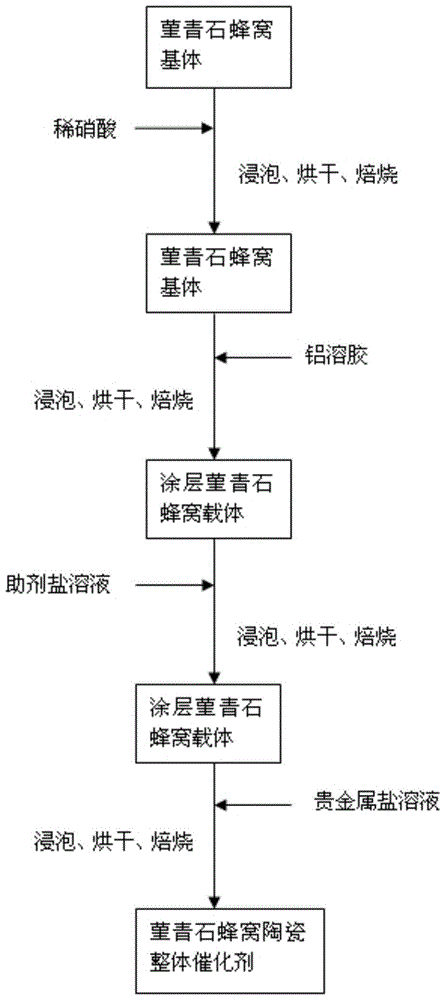

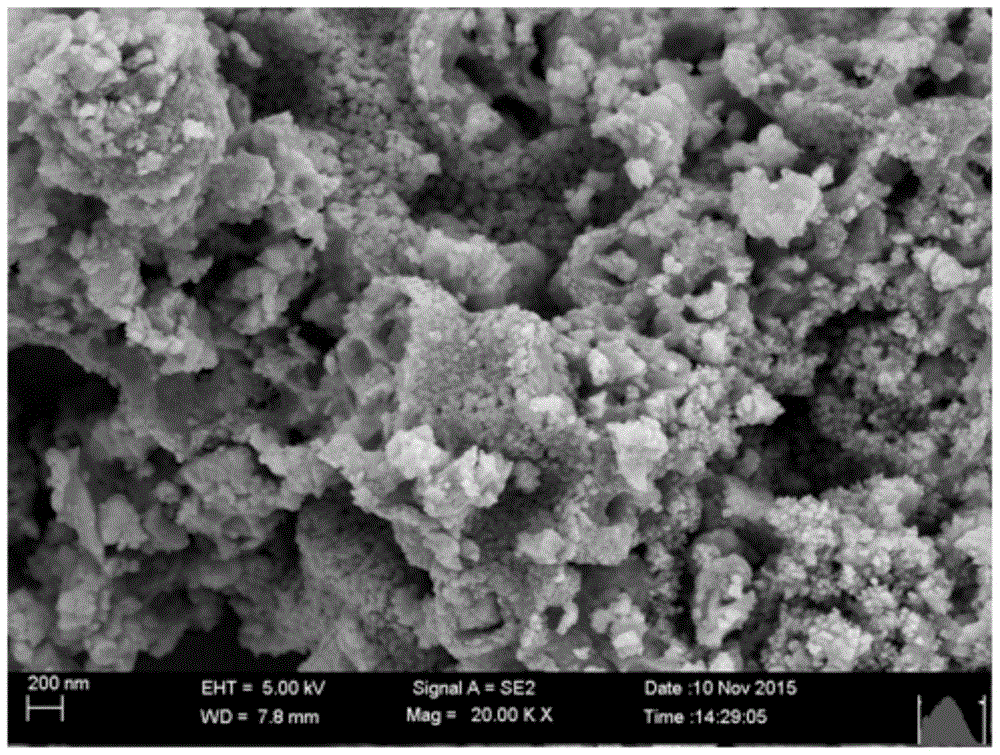

InactiveCN105709734AImprove bindingNot easy to fall offCatalyst activation/preparationIncinerator apparatusRare earthCordierite

The invention relates to a chemical catalyst preparation technology, and aims to provide a catalyst for low-temperature catalytic combustion of volatile aromatic hydrocarbons and a preparation method thereof. The catalyst is based on cordierite honeycomb ceramics, and the surface of the base body is sequentially provided with an aluminum coating, an additive coating and an active component layer from the inside to the outside; based on the total amount of the catalyst, the catalyst contains 85-90 wt% of the cordierite honeycomb ceramics, 8-12 wt% of the aluminum coating, 1-5 wt% of the auxiliary coating, and 0.05-0.5 wt% of the active component layer; wherein, the composition of the aluminum coating is alumina; the composition of the auxiliary coating is a rare earth metal oxide; The constituents of the active component layer are noble metals. The preparation process of the invention is simple, the preparation raw materials are easy to obtain, the specific surface area is large, the cost is low, and the catalytic combustion reaction of benzene series such as toluene has high catalytic activity; the active component has strong binding force with the matrix, and is not easy to fall off and crack It can still maintain high activity under high space velocity airflow and thermal shock.

Owner:ZHEJIANG UNIV

TiCN series nanometer gradient compound multi-layer coating and method for preparing same

InactiveCN101712215AHigh bonding strengthAvoid component mutationsLayered productsVacuum evaporation coatingEtchingAlloy

The invention discloses a TiCN series nanometer gradient compound multi-layer coating and a method for preparing the same. On hard-metal alloy, iron based tools with the Rockwell hardness of over HRC60 or a mould matrix, a TiN film, a gradient change Ti(CxN1-x) film and a TiCN film are coated in sequence to form the nanometer gradient compound multi-layer coating with a structure of TiN / Ti(CxN1-x) / Ti(CN), wherein the x is between 0 and 0.5. The method for preparing the coating comprises the steps of surface pre-treatment, pre-heating, surface washing and etching, preparation of a transition layer, preparation of a gradient layer, preparation of a surface layer and the like. The hardness HV of the coating prepared by the method reaches 28 to 32GPa, and the same matrix binding force of the coating is over 55N, the same matrix binding force and wear resistance of the TiCN series coating are improved, and the working efficiency and the service life of the tools and the mould are also improved.

Owner:SOUTH CHINA UNIV OF TECH

Implementation of microfluidic components, including molecular fractionation devices, in a microfluidic system

Owner:CYTONOMEST

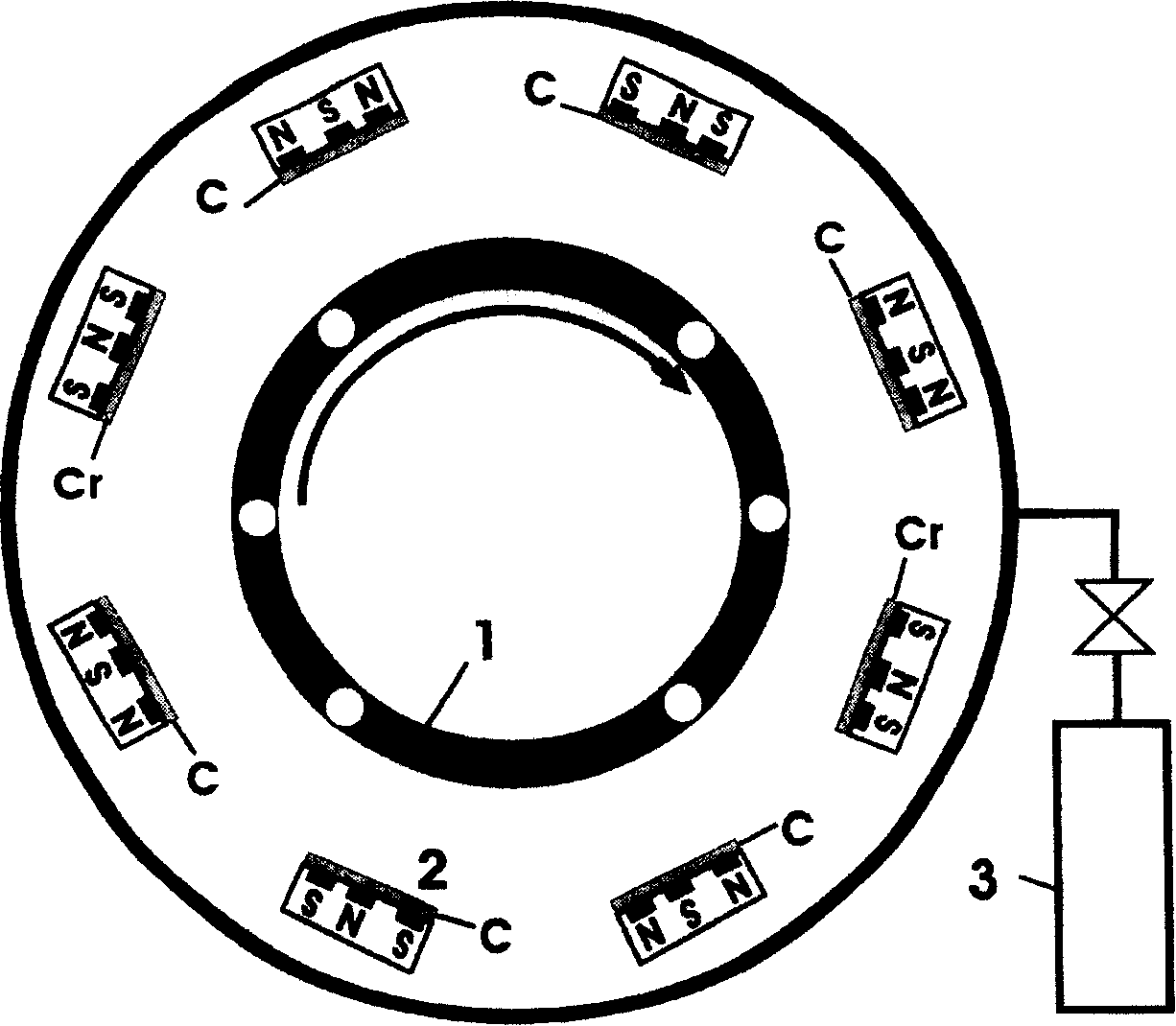

Diamond film containing chronium and its preparing method

InactiveCN1743503AImprove bindingEliminate internal stressVacuum evaporation coatingSputtering coatingIntermediate frequencyPulsed DC

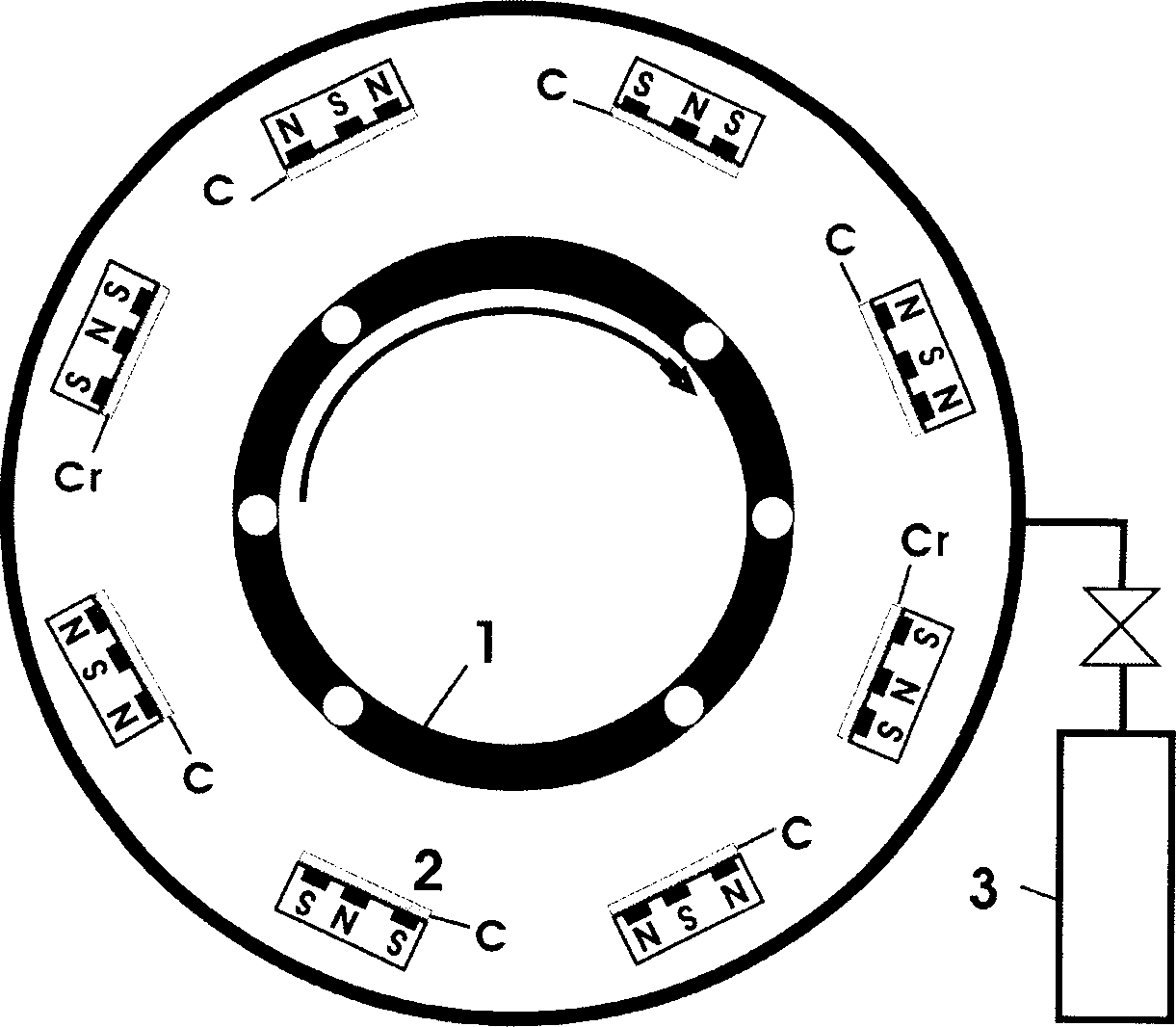

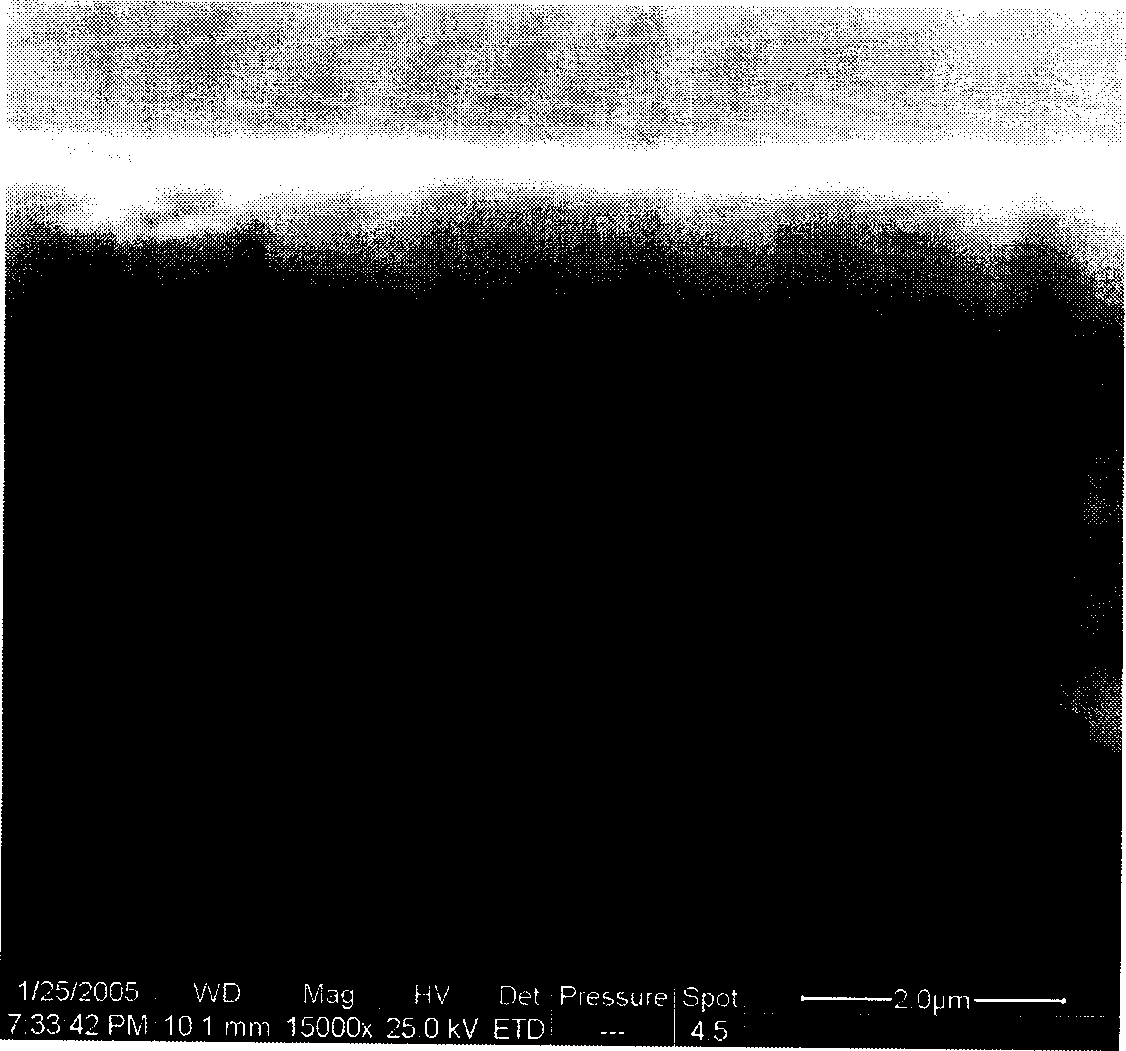

This invention discloses a diamond film containing Cr and its preparation method. Said film is a H-free film containing Cr deposited in gas phase on a matrix surface having the alternative condensed multi-layer gradient structure of Cr, CrNx, CryCz, Cr, CrNx, CryCz layers orderly from inside to outside along the vertical direction of the matrix surface, the film thickness is not less than 2 mum, which has a fine film / matrix binding force and good wearability. The preparation method includes utilizing the magnet control sputtering system to coat, the magnet control targets are a pair of unbalanced magnet controlled Cr targets and 1-4 pairs of un-balanced magnet controlled C targets, the supply of which is 20-250KHz IF AC supply, a pulse matrix negative bias voltage is applied on the armed coating matrix by single-level pulse DC supply, the sputtering gas is Ar.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Electrically conductive freestanding microporous polymer sheet

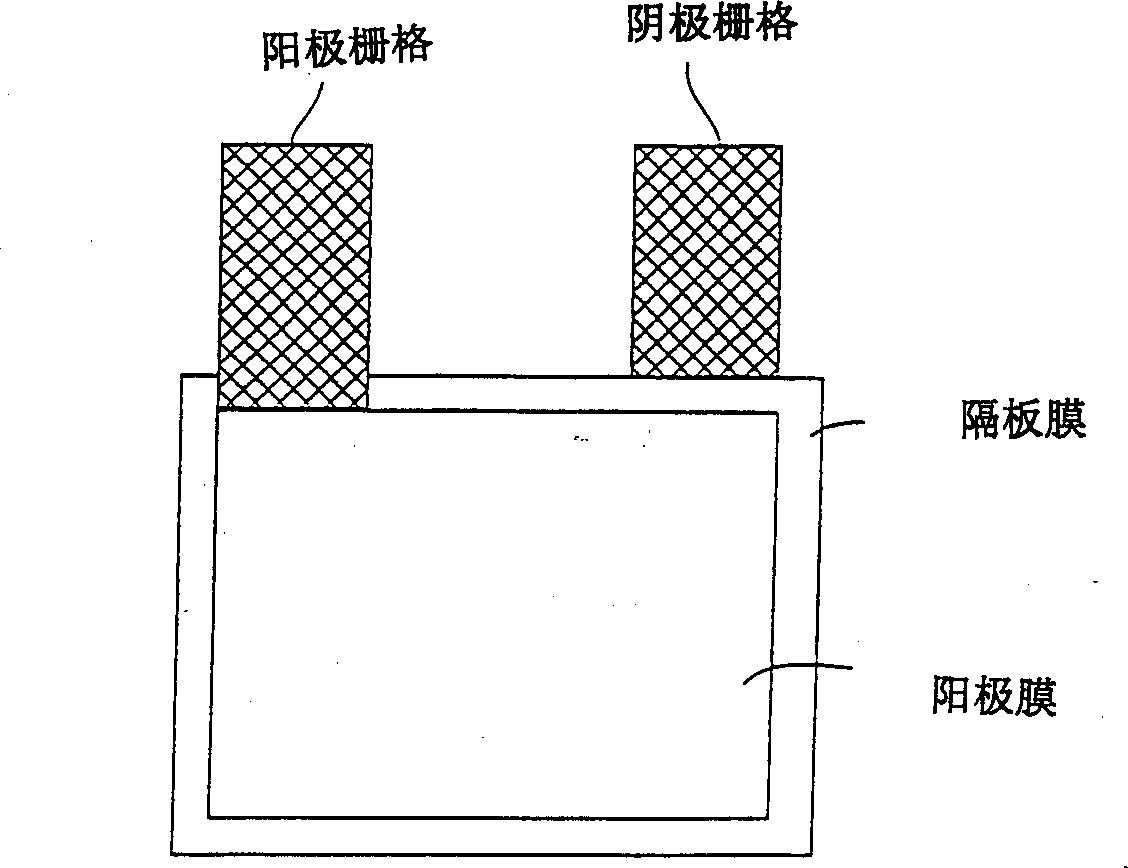

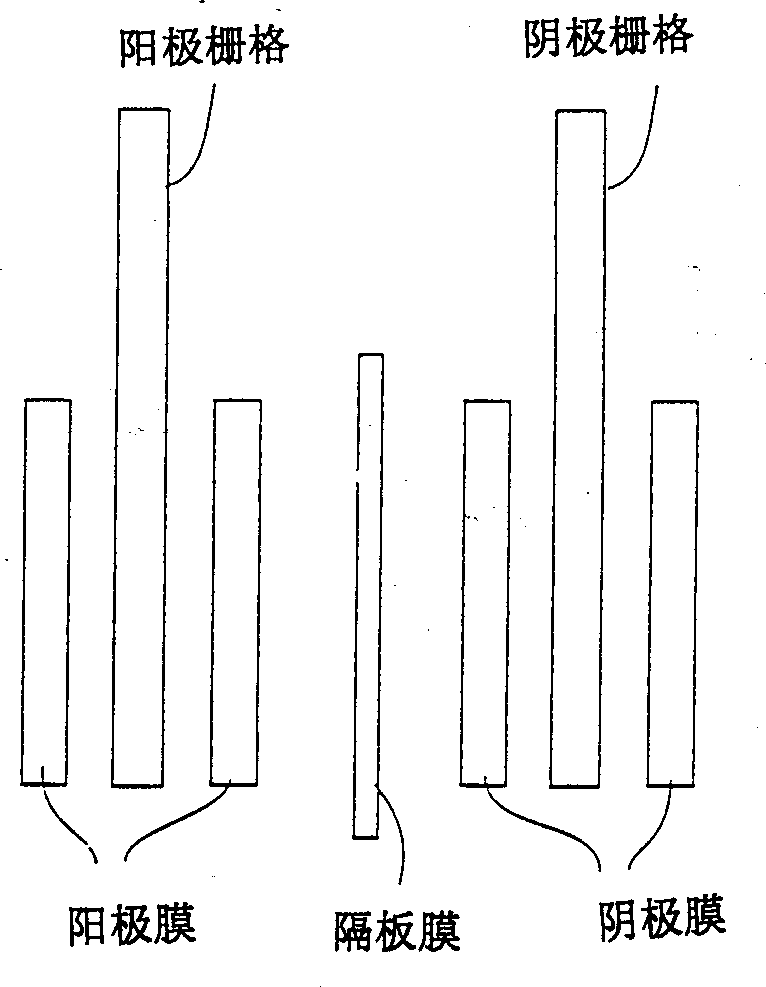

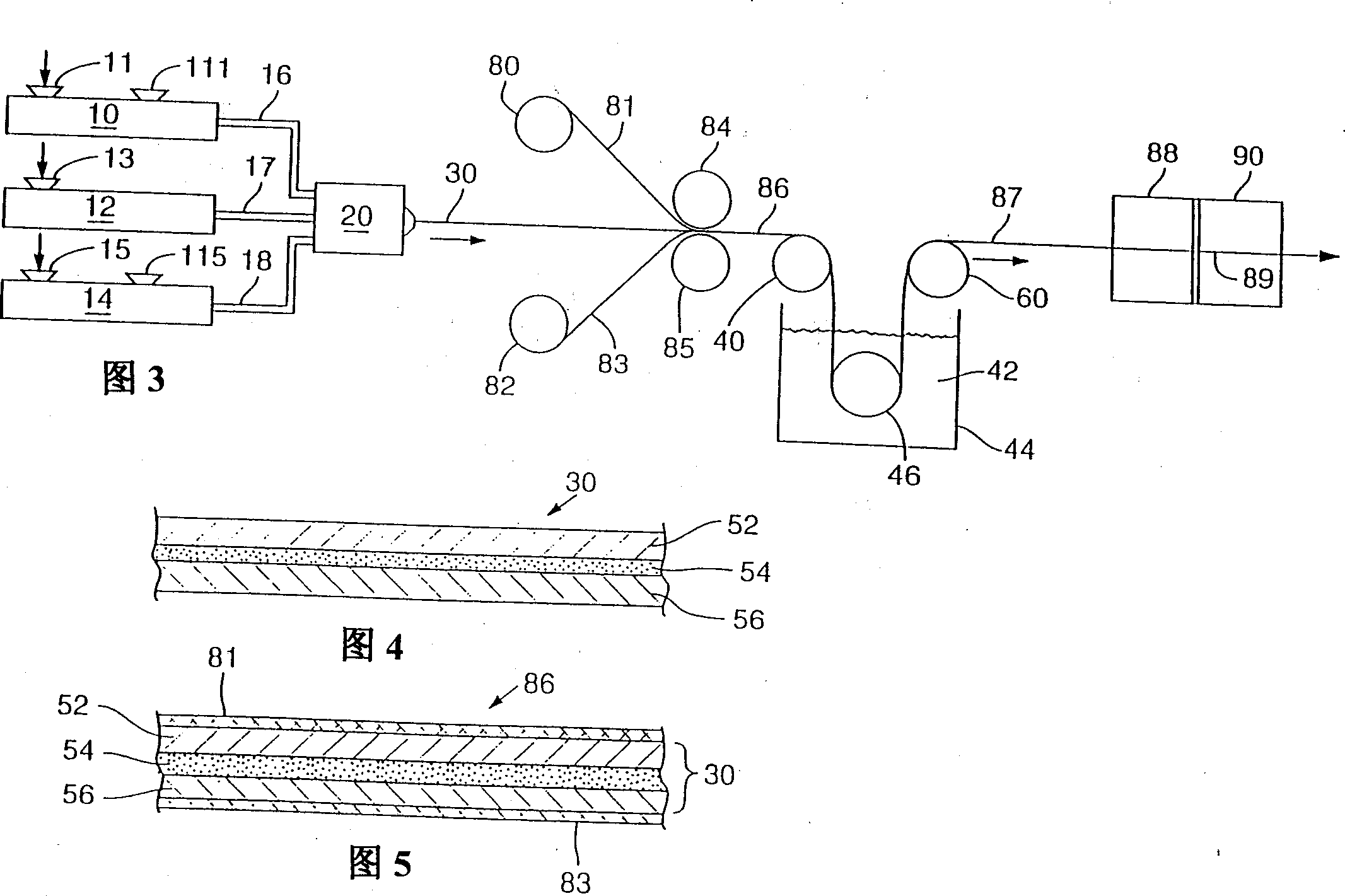

A freestanding, microporous polymer sheet (52, 56) is composed of a polymer matrix binding an electrically conductive matrix. The polymer matrix preferably includes UHMWPE, and the electrically conductive matrix is preferably in powder form. The UHMWPE is of a molecular weight that provides sufficient molecular chain entanglement to form a sheet with freestanding characteristics. Multiple microporous sheets (30) can be wound or stacked in a package filled with an electrolyte to function as electrodes in an energy storage device (86), such as a battery. Metallic layers (81, 83) can be applied to the microporous sheets to function as current collectors in such devices.

Owner:AMTEK RES INT

High porosity silica-containing microporous sheets

ActiveUS20150207121A1High porosityImprove mechanical propertiesLead-acid accumulatorsCell component detailsPorosityPolymer science

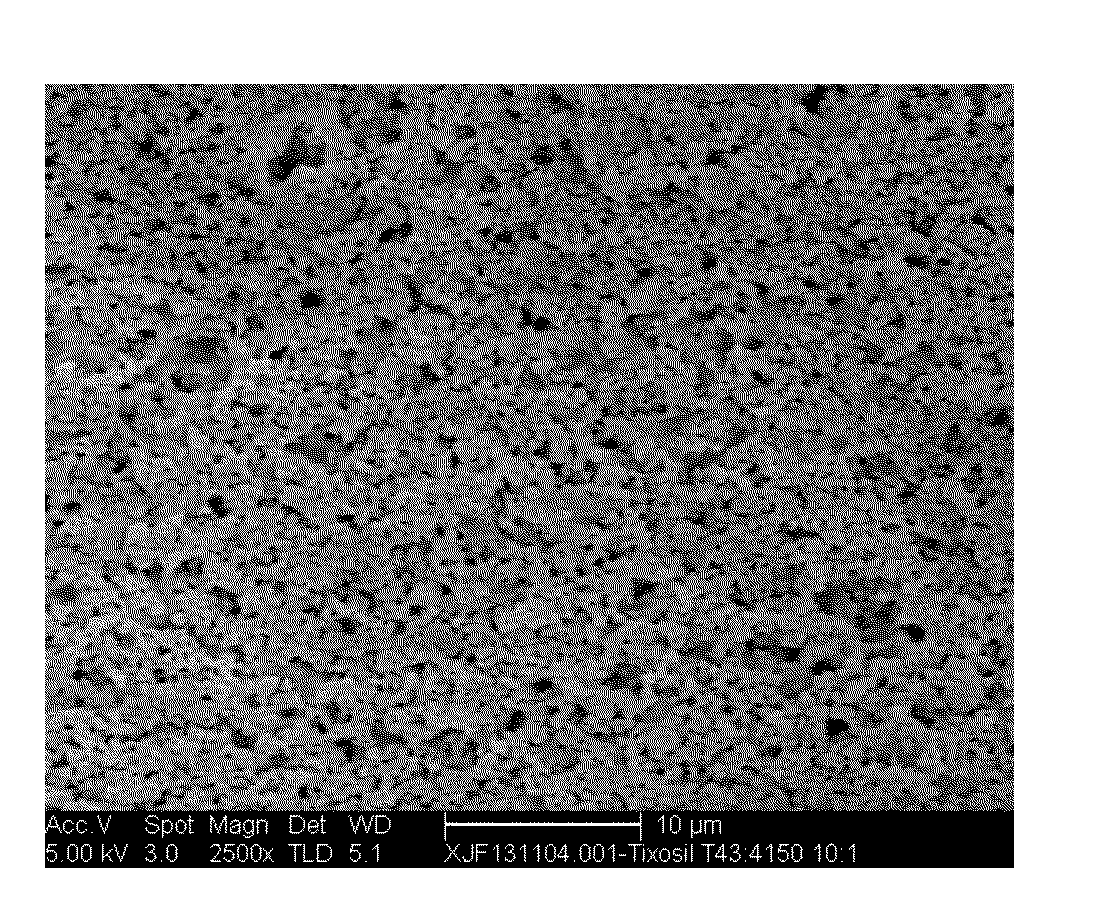

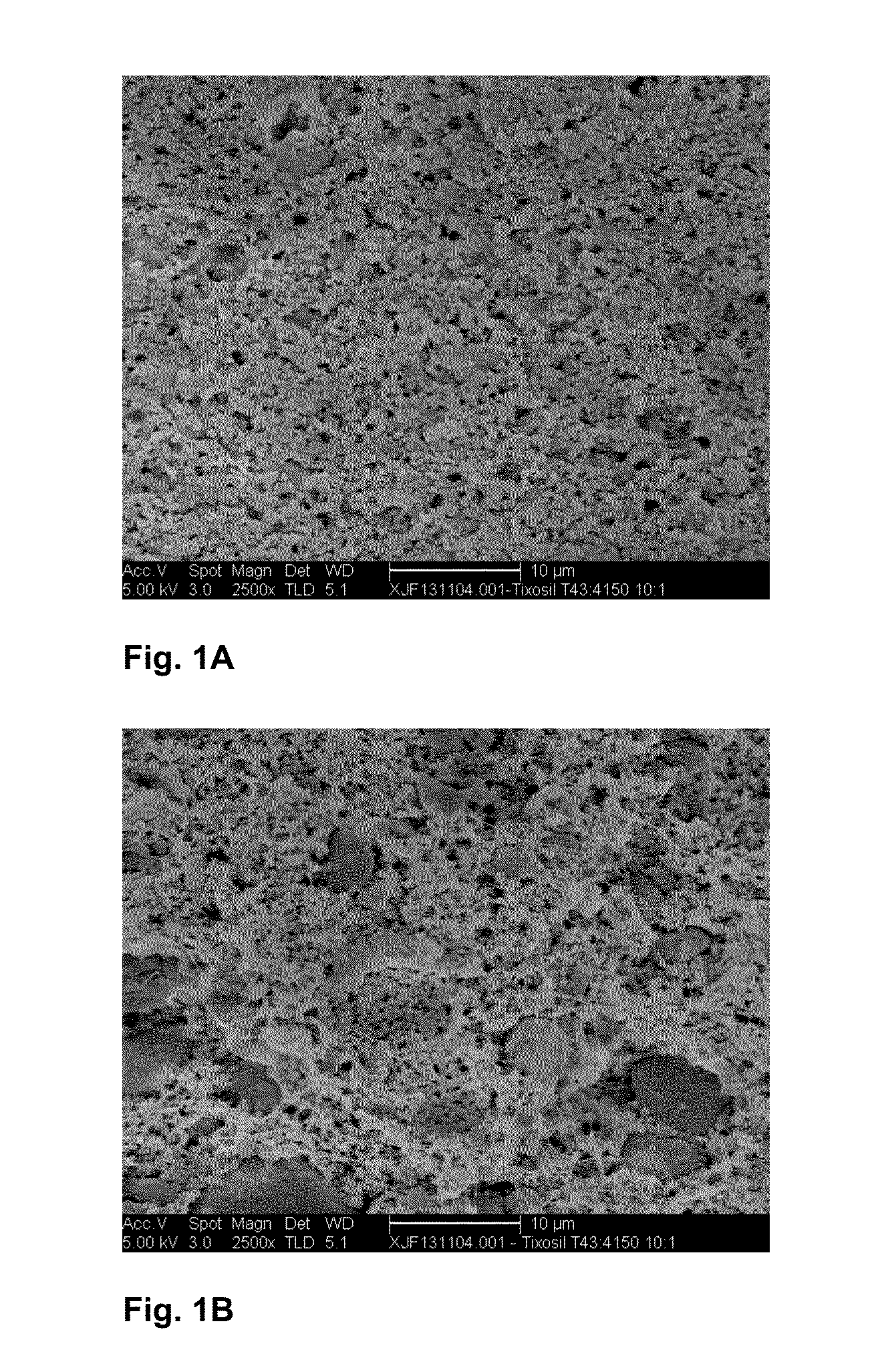

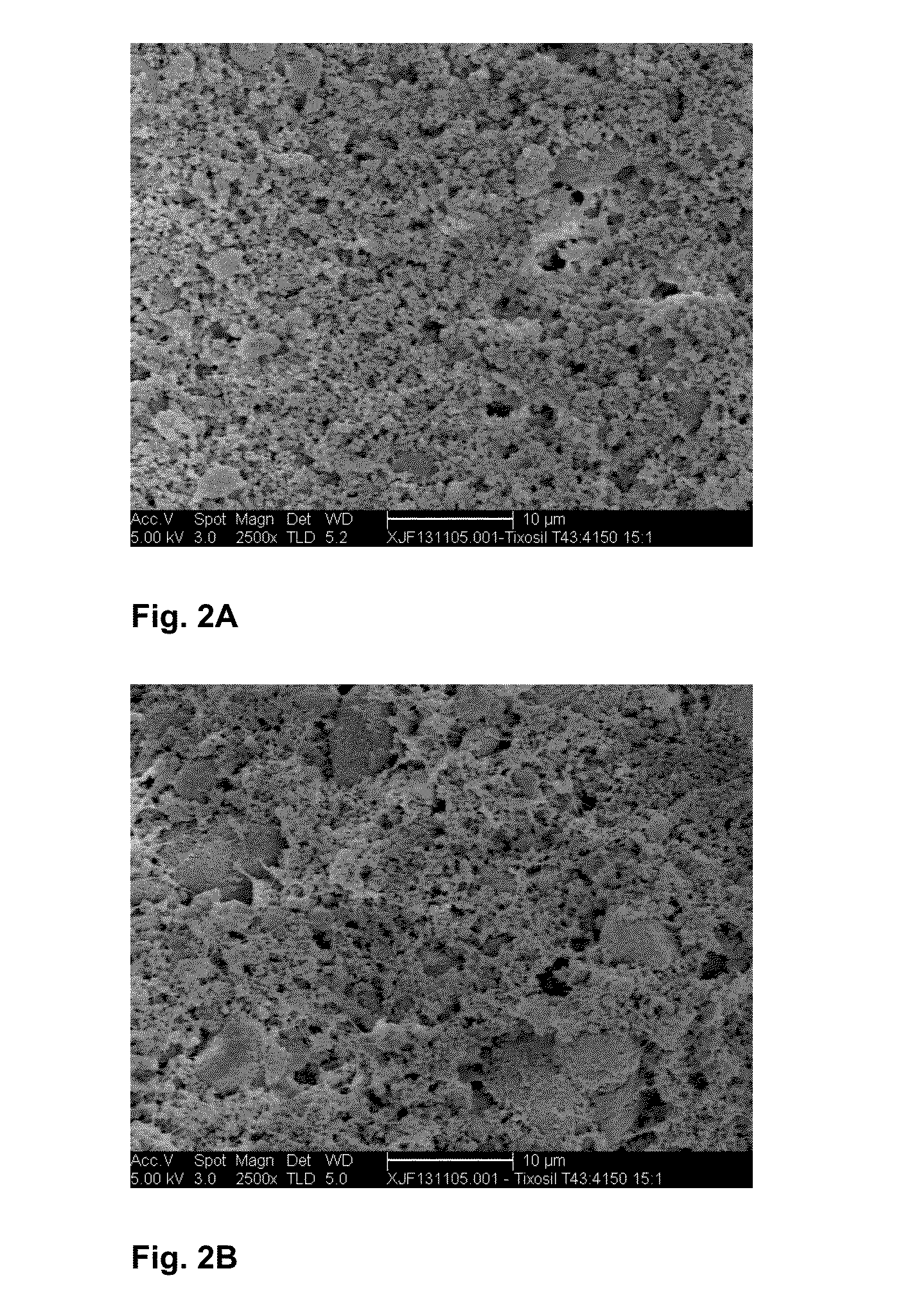

A flexible microporous polymer sheet having first and second opposite major surfaces comprises a polymer matrix binding a filler component that exhibits high oil absorption capacity in its initial state before the start of material processing. The polymer matrix includes a polyolefin component and has three-dimensional interconnecting and interpenetrating pore and polymer networks through which the bound filler component is distributed from the first major surface to the second major surface. The polyolefin and filler components are included in amounts that result in a microporous polymer sheet having between about 75% and about 90% porosity and containing less than about 10 wt. % polyolefin component. Preferred polyolefin and filler components include ultrahigh molecular weight polyethylene and high oil absorption precipitated silica, respectively.

Owner:AMTEK RES INT

Preparation method of metal doped hydrogen-free diamond-like carbon film

InactiveCN102965618AHigh film hardnessImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingDiamond-like carbonIon beam-assisted deposition

The invention discloses a preparation method of a metal doped hydrogen-free diamond-like carbon film which. The method is characterized in that an ion beam assisted deposition technology is utilized to prepare a metal doped hydrogen-free diamond-like film on a workpiece and a metal target and a graphite target are used for carrying out double-target sputtering. The preparation method comprises the following specific steps of: cleaning and activating ions on the surface of the workpiece and depositing to prepare the metal doped hydrogen-free diamond-like film. The prepared metal doped hydrogen-free diamond-like film has relatively higher film hardness, film-matrix binding force, elastic modulus, abrasion resistance, thermal stability and other performances. The preparation method is strong in technological operability and good in repeatability and can be applied to the surface treatment of silicon and various metal workpieces.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

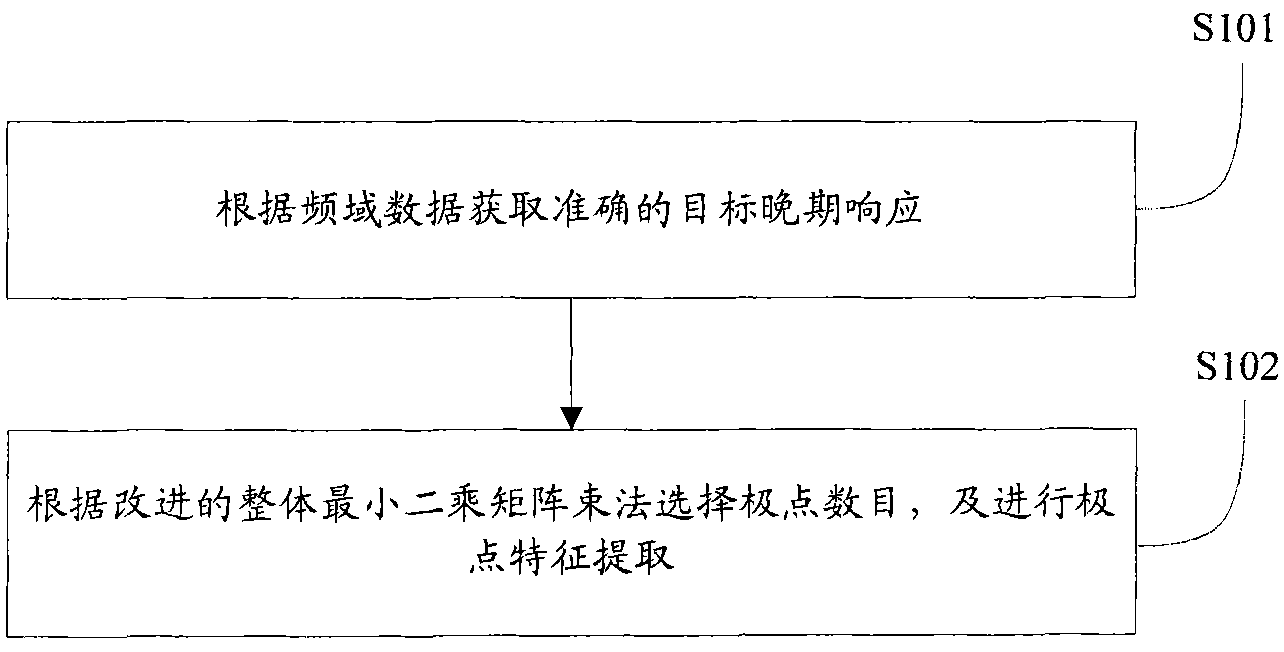

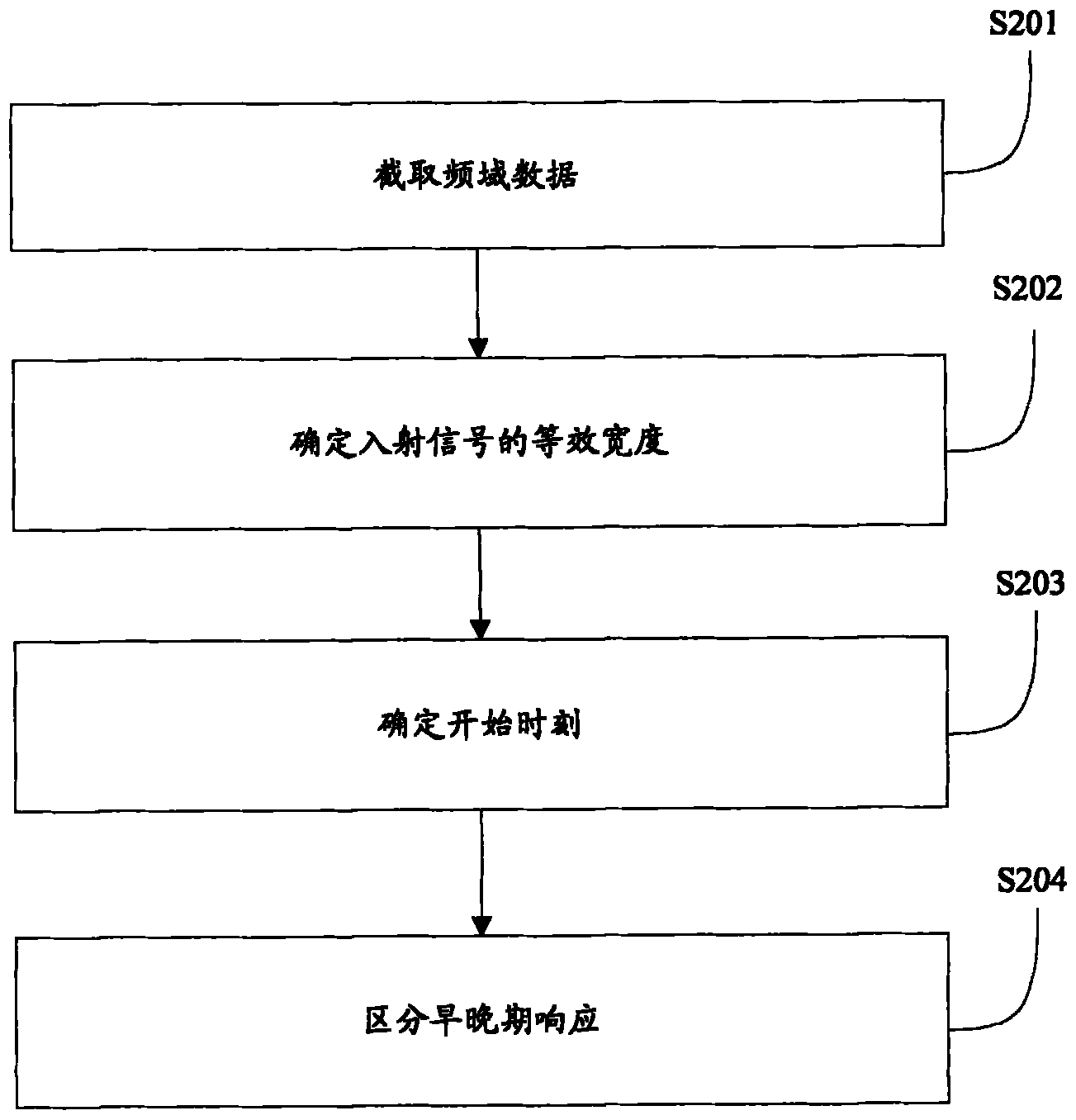

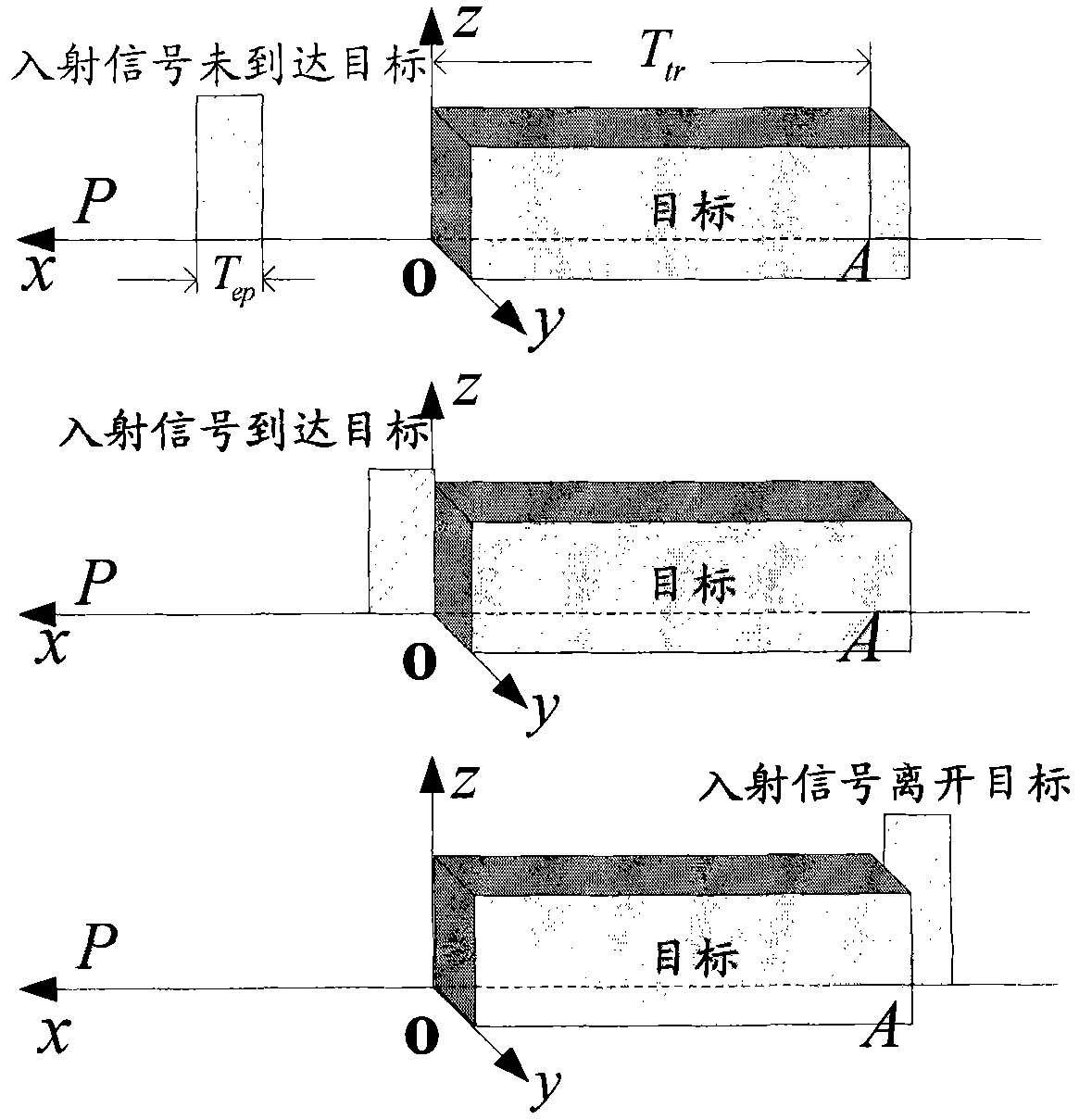

Method and device for extracting pole characteristic of complicated target

ActiveCN101776748AEasy accessSave test costWave based measurement systemsComputer scienceLeast squares

The invention provides a method for extracting pole characteristics of a complicated target, which comprises the following steps of: obtaining accurate target later period response according to frequency domain data; confirming the pole number according to the obtained target later period response and an improved integral least square matrix binding method and carrying out pole characteristic extraction. The invention adopts the frequency domain data which is can be acquired more easily by a calculation approach, thereby replacing a darkroom shrinking ratio test and saving a great amount of test cost. The invention can realize the pole characteristic extraction on the complicated target, such as various airplane and warship targets. The invention also provides a device for extracting the pole characteristic of the complicated target.

Owner:哈尔滨工大雷信科技有限公司

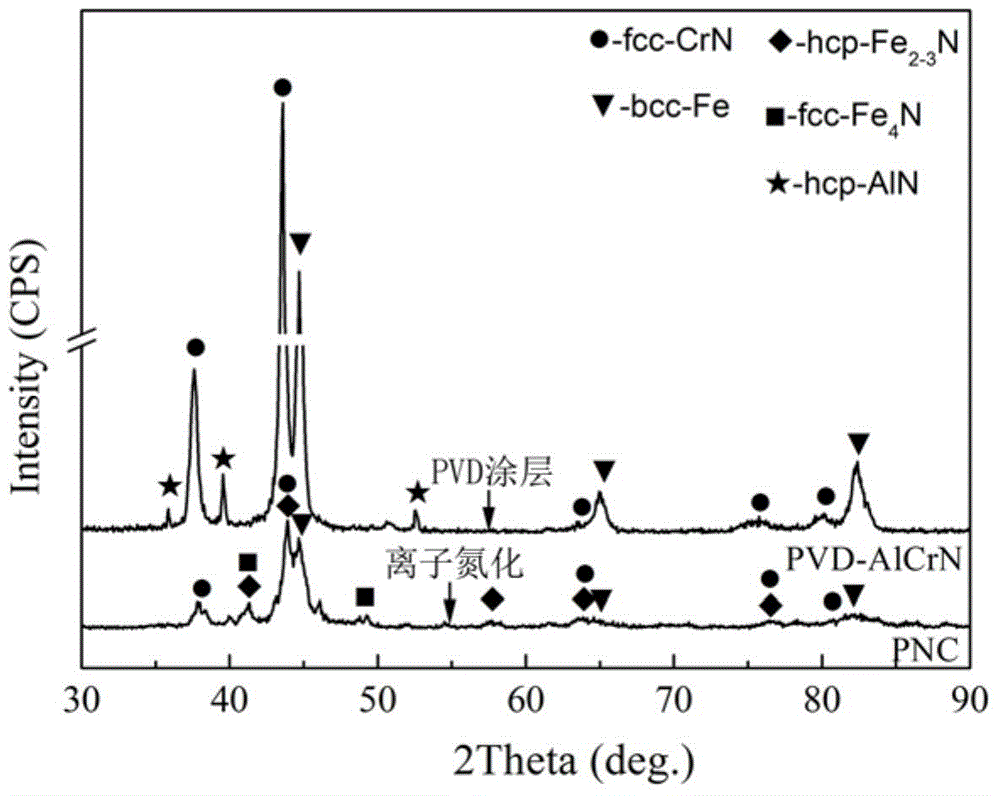

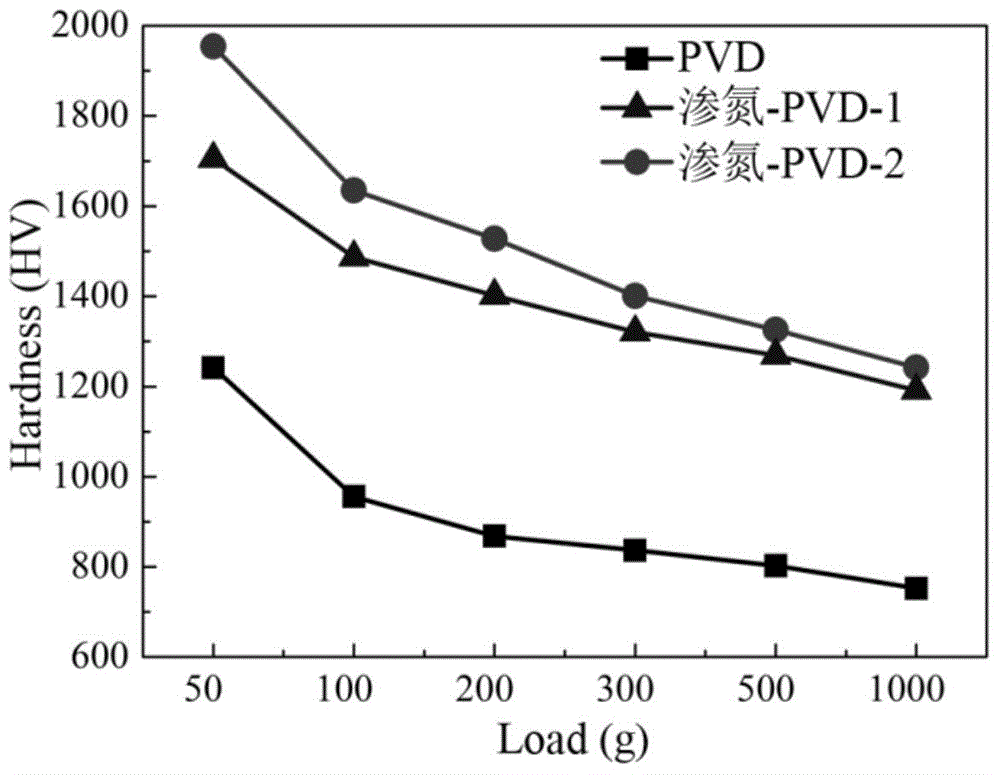

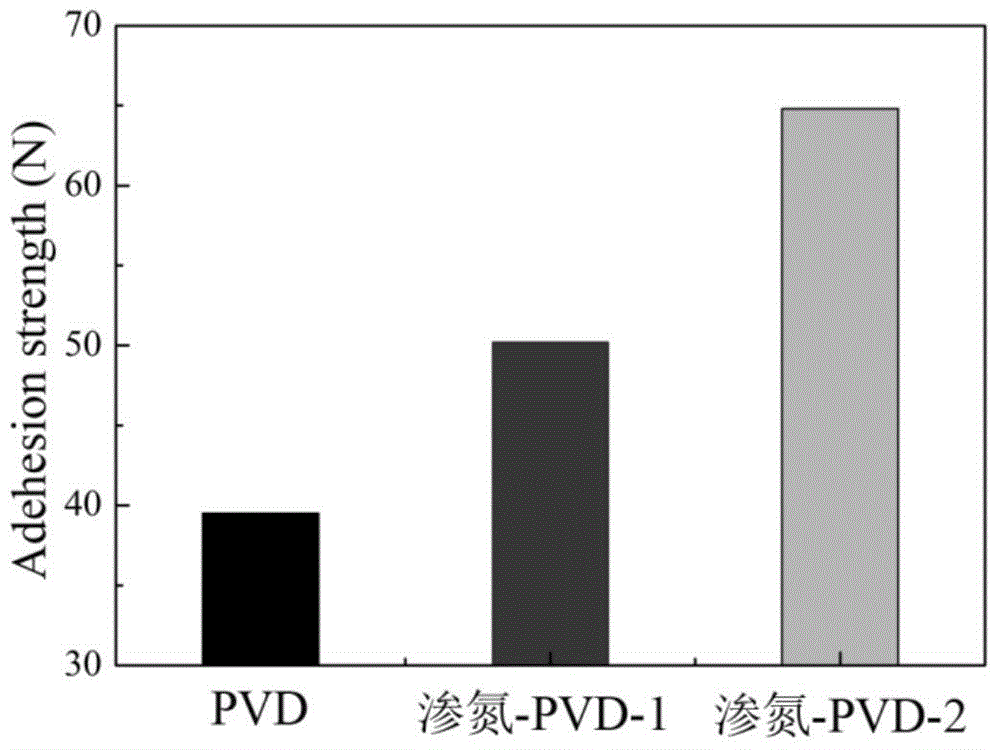

Nitriding PVD composite coating and preparation method thereof

The invention discloses a nitriding PVD (Physical Vapor Decomposition) composite coating and a preparation method thereof. The internal structure of a diffusion layer comprises a nitrogen-containing oversaturated martensitic structure, a metal nitrogen compound, a metal carbon compound and Fe4N phase; the internal structure of a compound layer comprises Fe4N phase of a face-centered cubic structure, CrN phase of the face-centered cubic structure, and Fe2-3N phase of a close-packed hexagonal structure; the internal structure of a PVD hard film layer mainly comprises fcc-(Cr, Al)N phase of the face-centered cubic structure and further comprises a small number of hcp-AlN phase of the close-packed hexagonal structure, and fcc-(Ti, Al)N phase of the face-centered cubic structure. With the adoption of the reasonable technologic optimization and adjustment and control of the structure, the decomposition of the compound layer can be inhibited; the Fe4N phase and the CrN phase in the compound layer become nucleation particles for phase epitaxial growth of the PVD hard film, so as to obviously increase the film-matrix binding force; the compound layer provides powerful support for the PVD hard film; moreover, the compound layer enables the stress on the film-matrix interface to be continuously changed, so as to improve the interfacial stress concentration situation, and improve the bearing capacity, the surface hardness and other mechanical properties of the composite coating.

Owner:安徽工业大学科技园有限公司

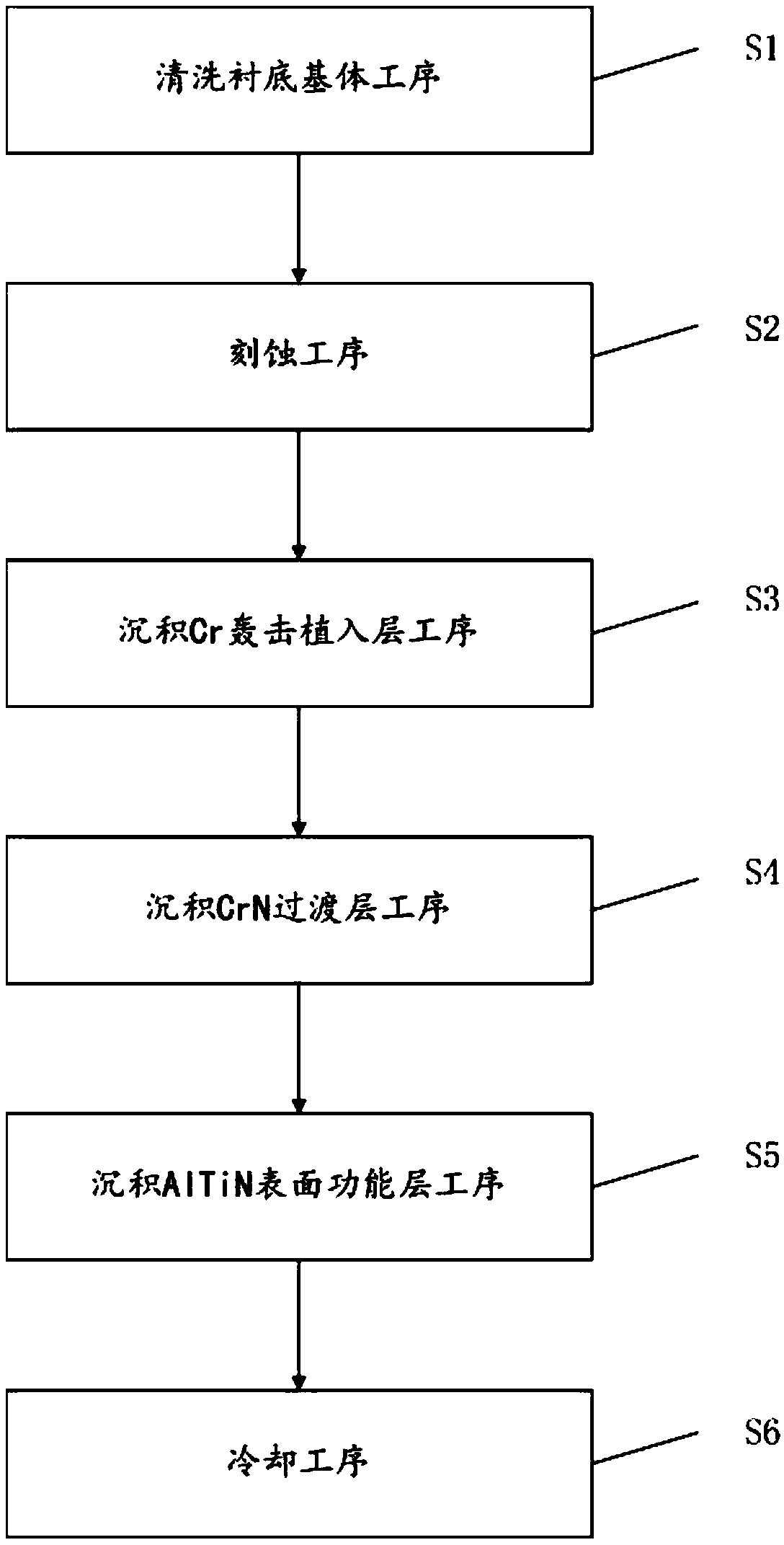

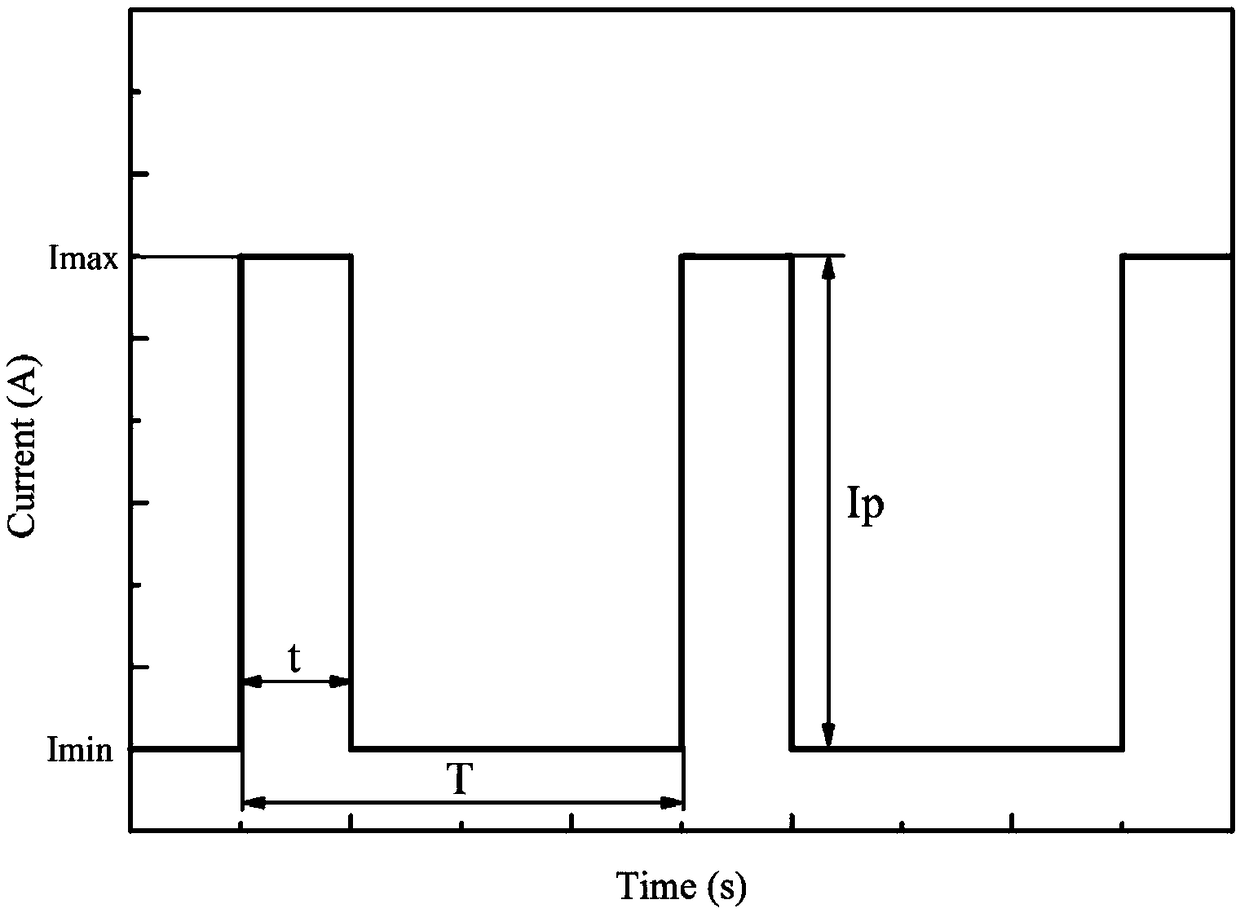

AlTiN coating and preparation method thereof

InactiveCN108796432AImprove bindingReduce the binding forceVacuum evaporation coatingSputtering coatingPulse dischargeBinding force

The invention discloses an AlTiN coating and a preparation method thereof. The AlTiN coating is composed of a Cr bombardment implanting layer, a CrN transition layer and an AlTiN surface function layer. The binding force of the AlTiN coating and a matrix is strong enough, the peeling-off phenomenon is not prone to being generated, and the friction coefficient is small under high temperature. The preparation method comprises a matrix cleaning procedure, an etching procedure, a Cr bombardment implanting layer deposition procedure, a CrN transition layer deposition procedure, an AlTiN surface function layer deposition procedure and a cooling procedure. In the three specific deposition procedures, the cathode pulsed arc technology is applied, and higher-density plasma can be generated during pulse discharging by adjusting the maximum value, the minimum value, the duty ratio and frequency of currents output by a pulsed arc power source; and compared with an AlTiN coating prepared by a traditional arc ion plating technology, the AlTiN coating prepared through the method has the advantages that the surface roughness of the coating is obviously reduced, the number of large particles on thesurface is obviously reduced, the film layer compactness is higher, the film-matrix binding force is higher, and the friction coefficient under the high temperature is lower.

Owner:GUANGDONG UNIV OF TECH

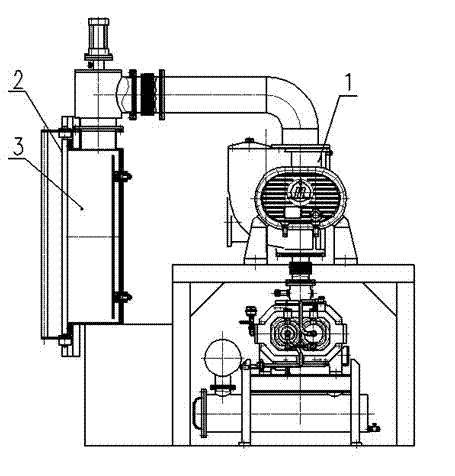

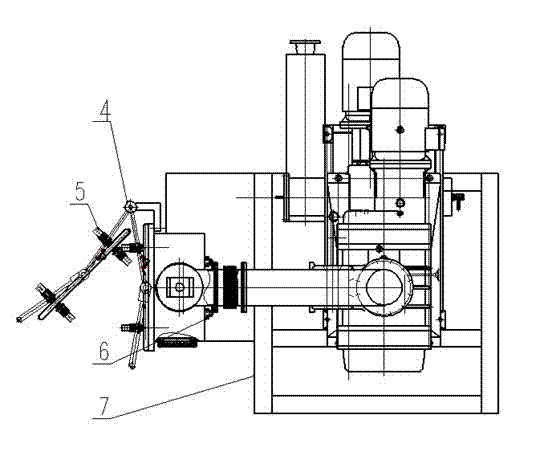

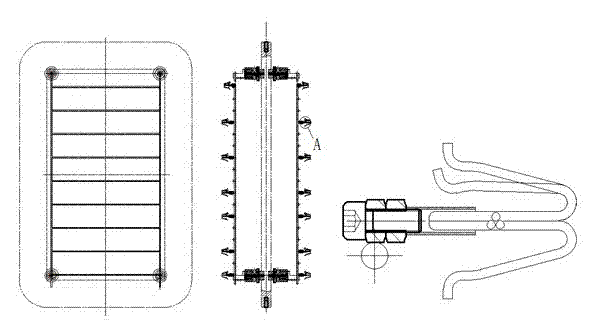

Plasma cleaning equipment in two-sided turnover door structure

InactiveCN102858077AImprove surface activityImprove adhesionVacuum evaporation coatingSputtering coatingMeasurement pointHigh pressure

The invention discloses plasma cleaning equipment in a two-sided turnover door structure. The plasma cleaning equipment comprises a vacuum system, a door, a vacuum chamber body, a hinge, a rack component, a high-pressure lead-in component, a support, a polar plate, a hinge fixing plate, a hinge shaft, a hinge plate, a positioning device, a rotary shaft, a handle and a computer control system, wherein the vacuum system has the main characteristics that the plasma cleaning equipment consists of a roots pump (main pump), a screw pump (backing pump) and a roughing valve; the door has the main characteristics that the door consists of a flat plate, and a lamp rack component is arranged on the flat plate; the vacuum chamber body has the main characteristics that the vacuum chamber body consists of a shell; a sealing ring, an air suction opening, an observation window, an atmosphere point measurement point, an air charging system, a gauge tube port and an air entraining device; and the air entraining device comprises a precise gas mass flowmeter. The plasma cleaning equipment has the advantages that compared with a lamp processed by the traditional equipment, the film-matrix binding force and the reflective rate after the lamp processed by the plasma cleaning equipment is subjected to vacuum coating can be improved greatly. Compared with the traditional equipment, the plasma cleaning equipment is simple in structure, smaller in occupied area, shorter in production cycle and higher in efficiency.

Owner:常州大成绿色镀膜科技有限公司 +2

Combined strengthening treatment method for plasma immersion ion implantation and deposition on surfaces of spallation target balls

ActiveCN108977759AImprove wear resistanceHigh hardnessVacuum evaporation coatingSputtering coatingBinding forceMaterials science

The invention relates to the technical field of powder metallurgy, and more specifically, discloses a combined strengthening treatment method for metal plasma immersion ion implantation and depositionon the surfaces of spallation target balls. The strengthening treatment method comprises the steps of carrying out pre-treatment of the spallation target balls, carrying out TiSiN, TiAlN, TiAlSiN, TiAlSiN / h-BN ion implantation and deposition, and the like. The method has the advantages that the problems that the wear rate of the spallation target tungsten-iron-nickel target balls in a non-intermetallic compound form prepared through a powder metallurgy technology is high, the residual stress between a thin film and a matrix is large, the film-matrix binding force is poor, and the bearing capacity of a single film layer is poor can be solved, the surface of the thin film is effectively prevented from being peeled off, and a functionally gradient composite material which is high in film-matrix binding force, high in hardness, low in friction coefficient and high in wear resistance can be prepared.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

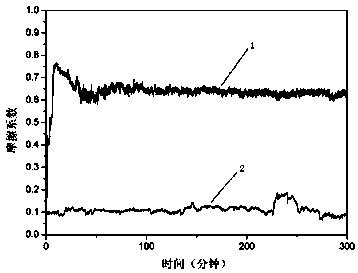

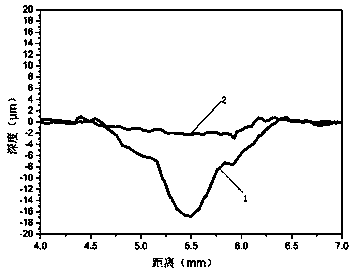

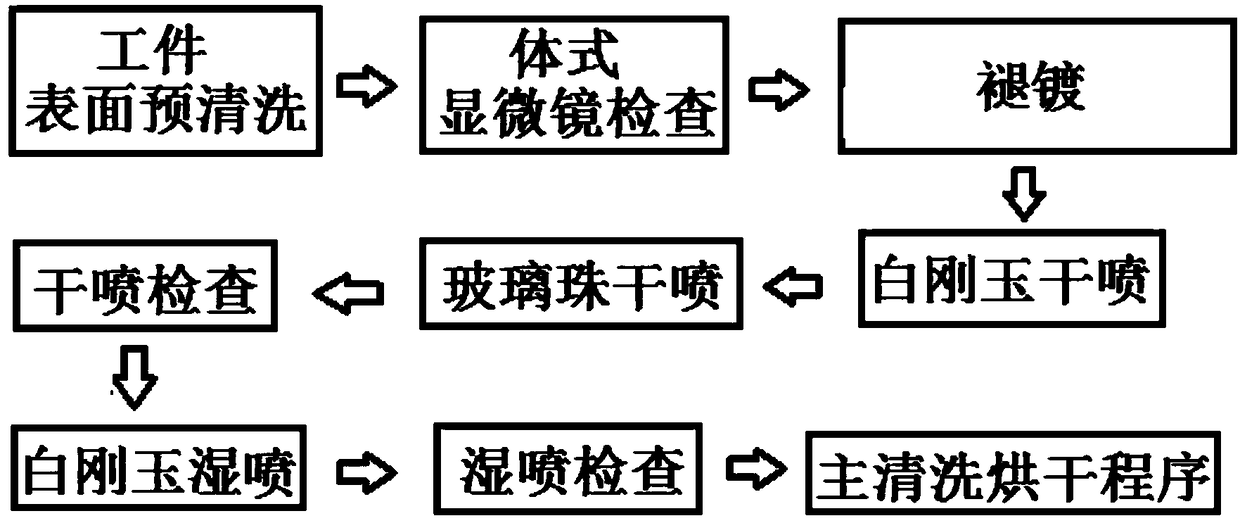

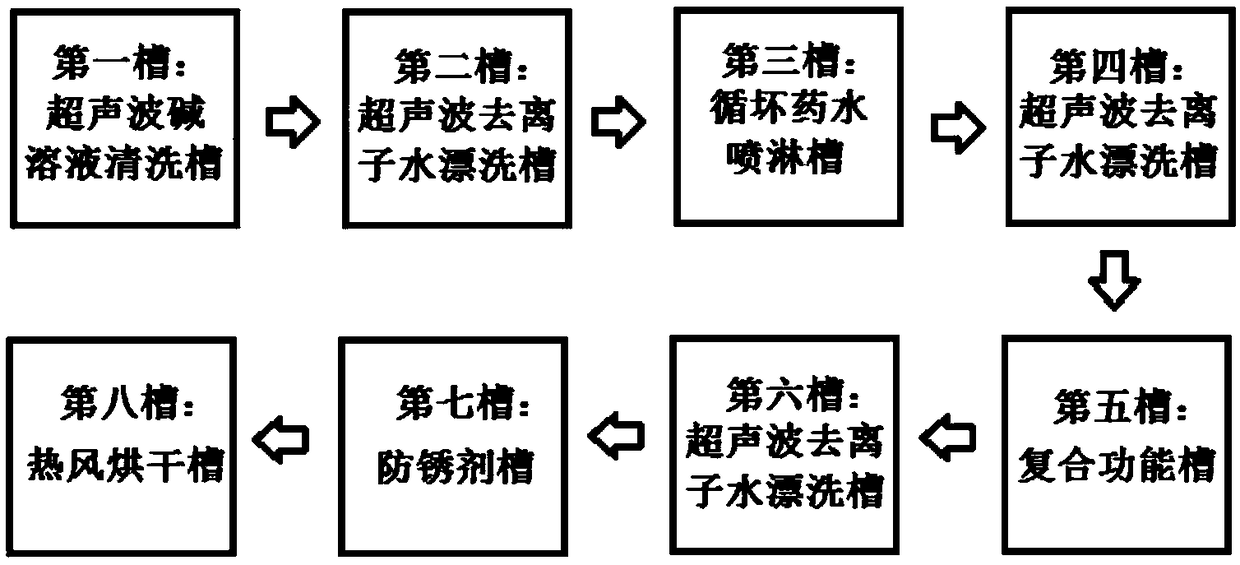

Cutter surface plasma vacuum coating pretreatment process

ActiveCN109182963AEfficient removalExtended service lifeVacuum evaporation coatingSputtering coatingSand blastingBinding force

The invention discloses a cutter surface plasma vacuum coating pretreatment process which comprises the following steps: white corundum dry spraying; glass bead dry spraying; white corundum wet spraying; main cleaning; and drying. According to the cutter surface plasma vacuum coating pretreatment process disclosed by the invention, a sand blasting method which integrates the white corundum dry spraying operation, the glass bead dry spraying operation and the white corundum wet spraying operation is selected, so that residues on the surface of a cutter can be thoroughly removed; after the removal of burrs, the cutting edge of the cutter is rounded to a certain extent, so that the service life of the cutter can be effectively prolonged under the premise that the binding force is guaranteed;and for slotting cutters, the cutter surfaces can be effectively treated under the circumstance that cutting edges are protected, and the film layer and matrix binding force can be improved.

Owner:合肥永信信息产业股份有限公司

Method for preparing artificial stone grinding sheet

ActiveCN108544384AImprove yield rateHigh chemical activityNon-macromolecular adhesive additivesAbrasion apparatusMelamine formaldehyde resinArtificial stone

The invention discloses a method for preparing an artificial stone grinding sheet. The method comprises the steps that (1) melamino-formaldehyde resin and filler are dosed according to the weight ratio of (40%-60%):(25%-40%); (2) carborundum and white corundum are added according to the weight ratio of (0-15%):(0-5%), mixing is carried out, and a matrix binding agent is prepared; (3) then diamondparticles are added into the matrix binding agent according to the weight ratio of 5%-15%, full stirring is carried out for more than 10 hours, and evenly mixed powder is prepared; and (4) the evenlymixed powder is put in a steel mold, leveling is carried out, nylon hook cloth is put in the steel mold, finally a pressing head is put in, the steel mold and the pressing head are put on an oil pressto be heated, sinter molding is carried out. The use sharpness of the grinding sheet special for artificial stone polishing is greatly improved, the service life of the grinding sheet is greatly prolonged, and the sharpness and the service life are more than two times those of a traditional grinding sheet, and the traditional grinding sheet can be replaced well; and the beneficial effects that dyeing and burning are avoided, the polishing effect is good, the yield is high, and the machining efficiency is remarkably improved are achieved.

Owner:QUANZHOU ZHONGZHI NEW MATERIAL TECH

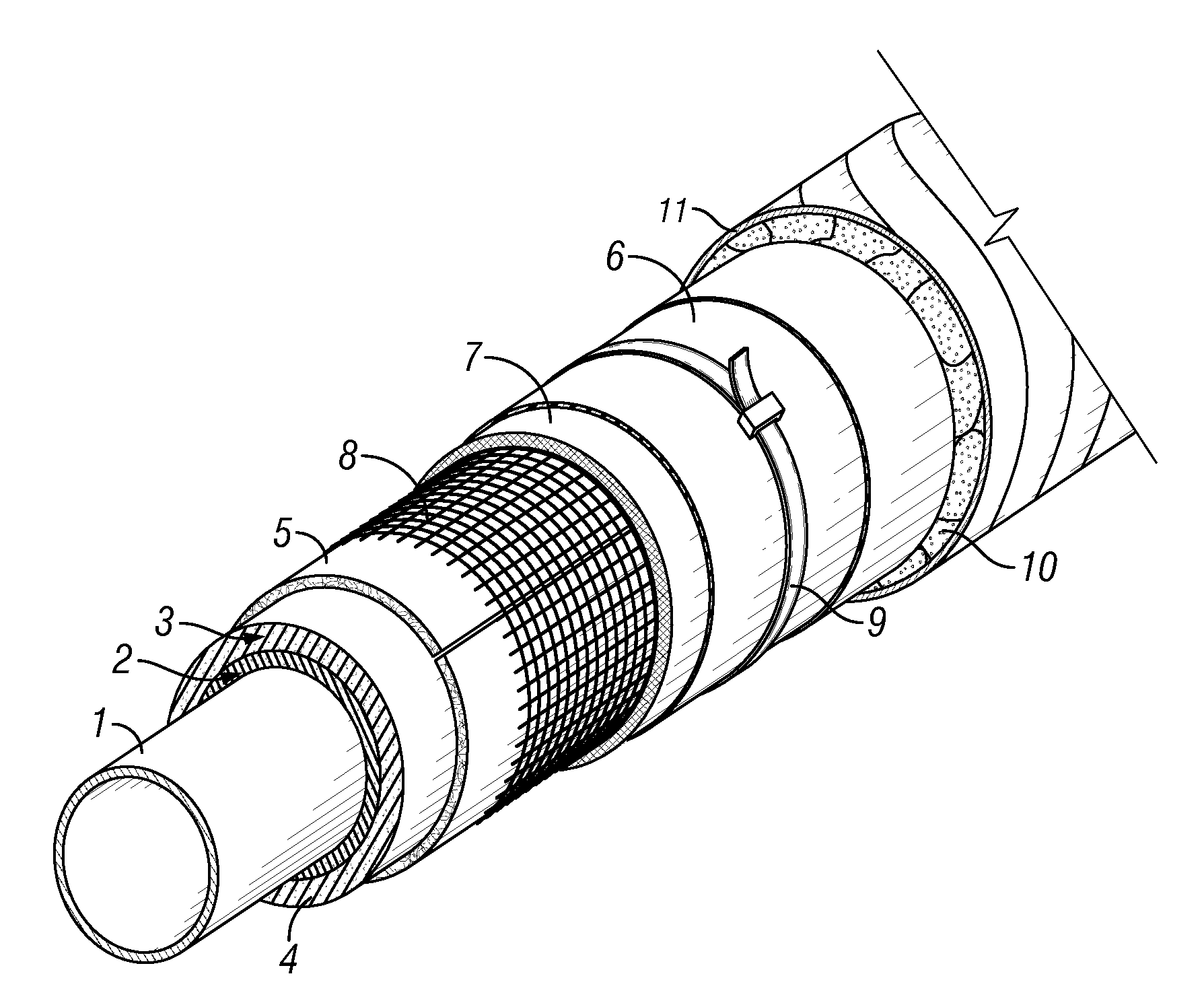

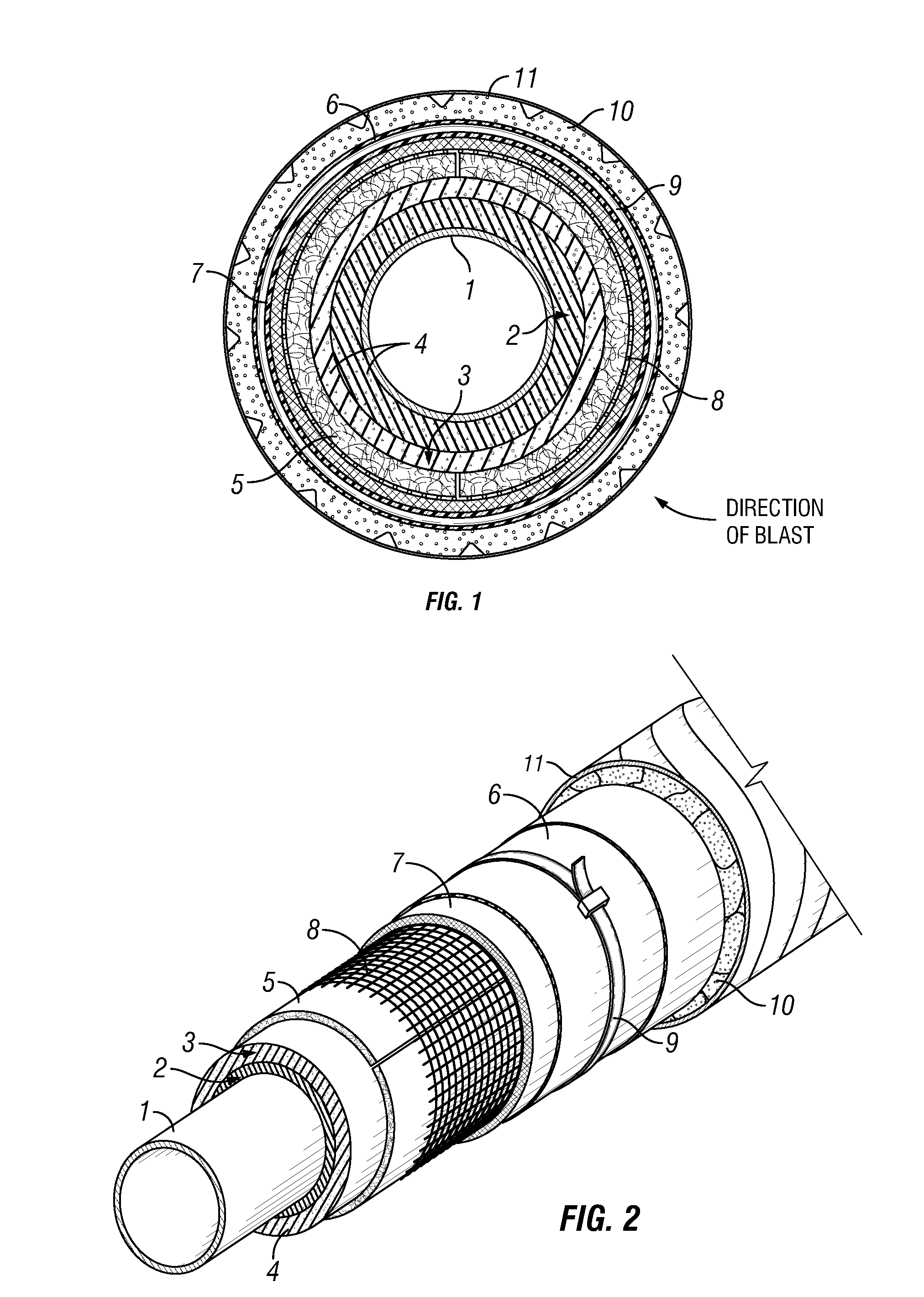

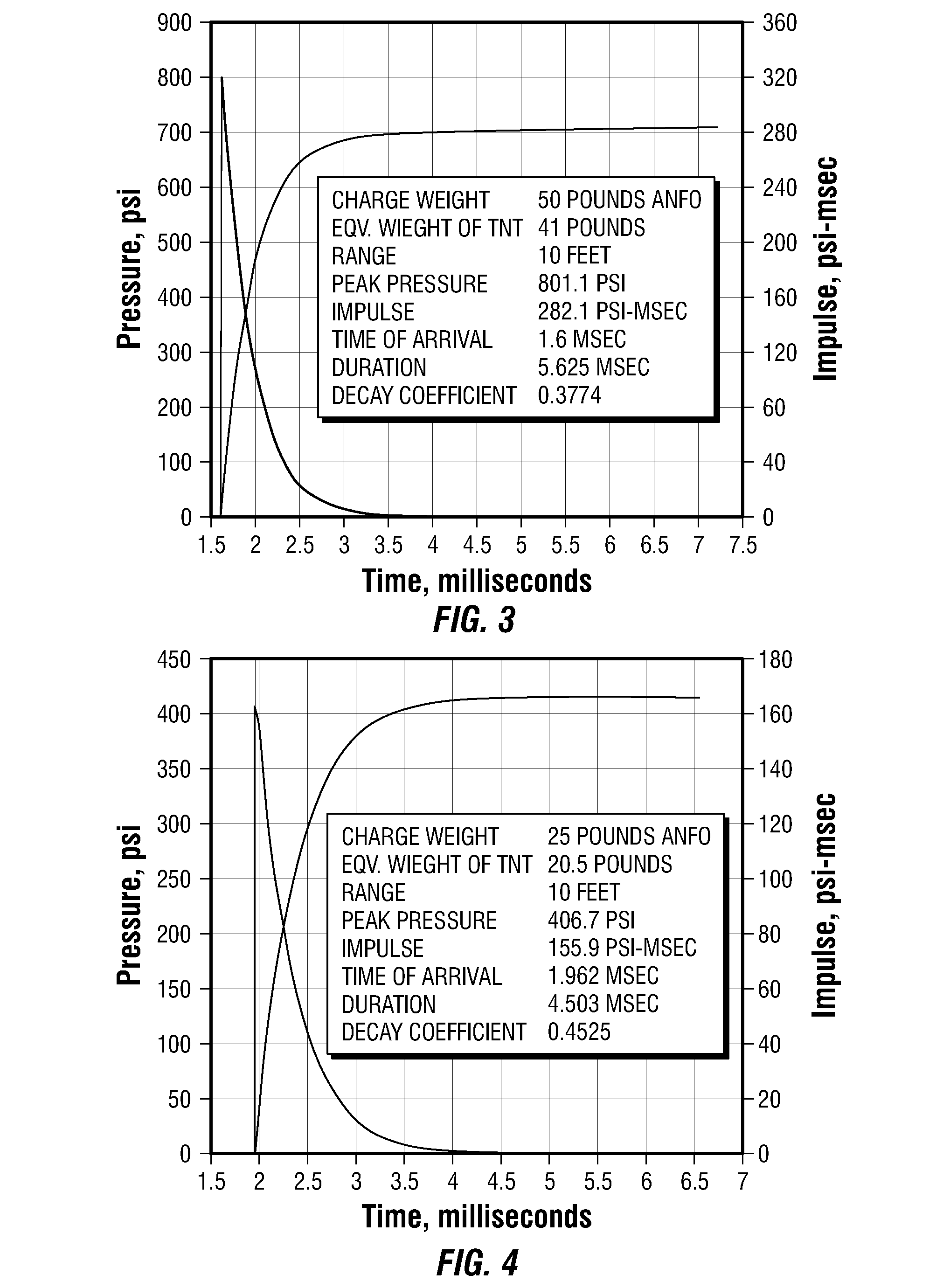

Blast resistant pipe protection system and method

The present invention is directed to generally to protection of structures from explosives, and specifically to a blast resistant pipe protection system and method for using same. The present invention is directed to a system and method for protecting a pipe. In some embodiments, the present invention is directed to a system for protecting a pipe, comprising an energy absorbing inner matrix bound to the pipe; an outer wrap comprising fire resistant foil; and a blast resistant material disposed between the inner matrix and the outer wrap, wherein the blast resistant material comprises Purlite. In some embodiments, the present invention is directed to a method for protecting a pipe comprises binding an energy absorbing inner matrix to the pipe; disposing Purlite around the inner matrix; and wrapping the Purlite with fire resistant foil.

Owner:ROK INVESTMENT GROUP

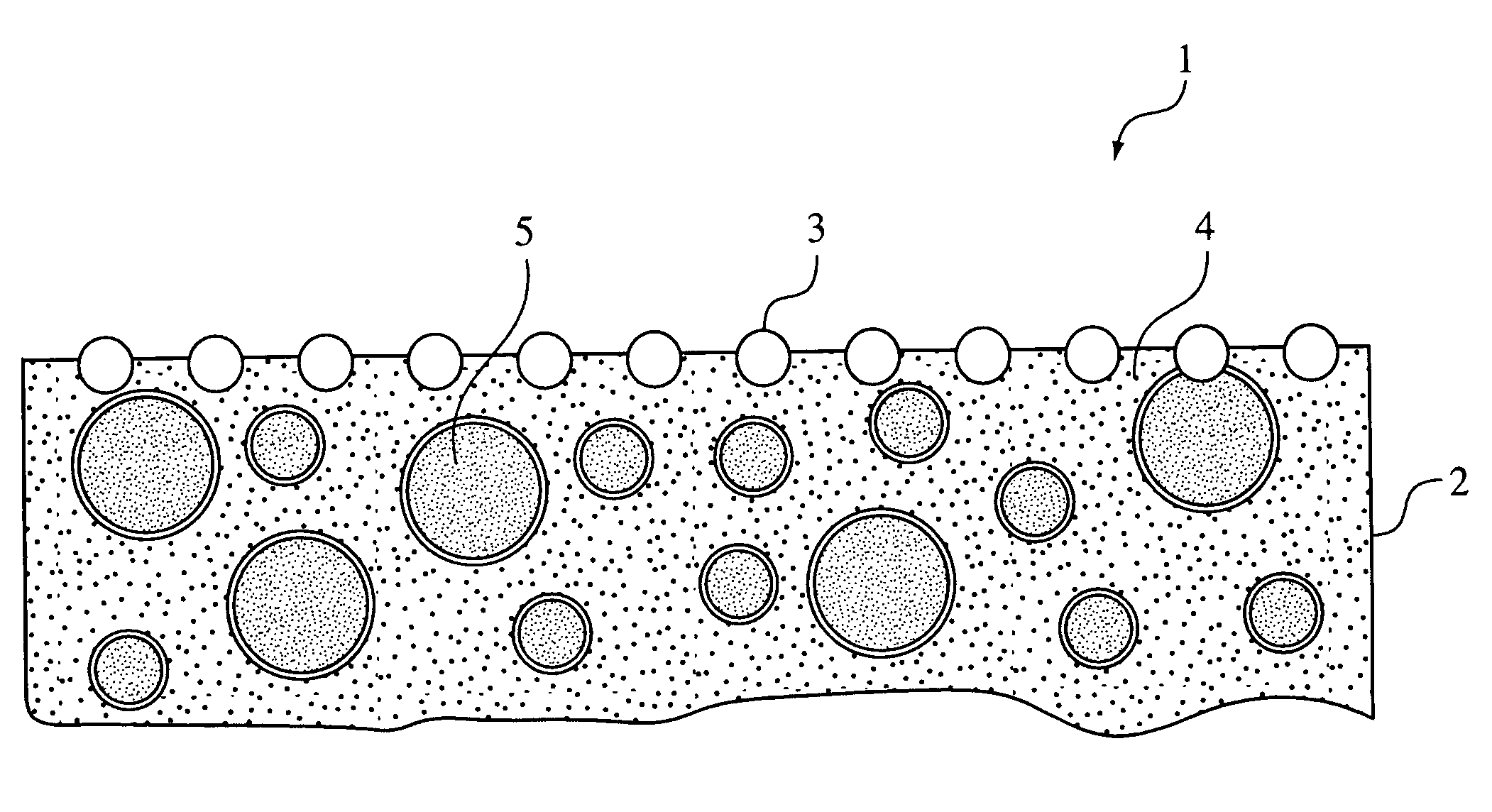

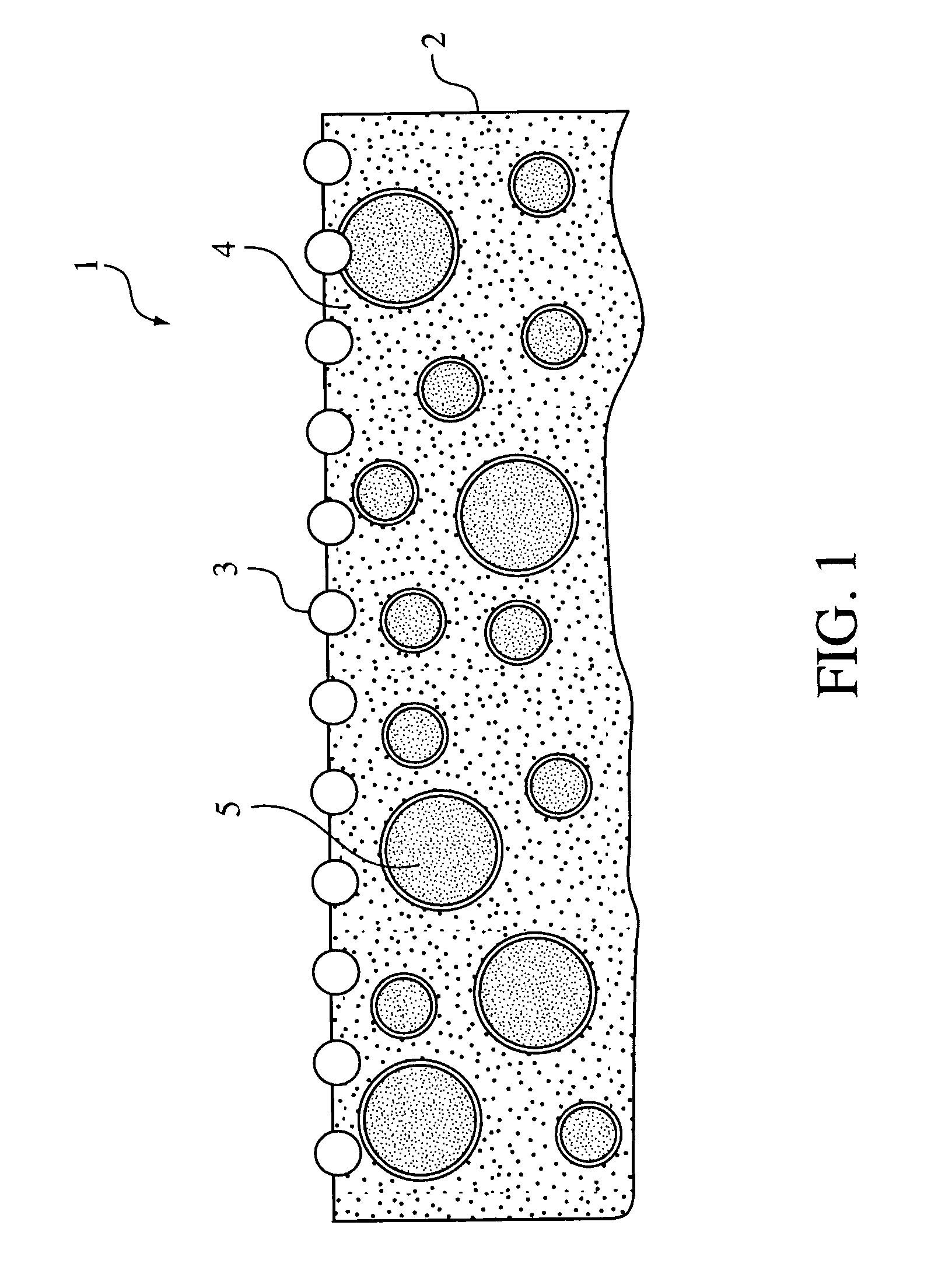

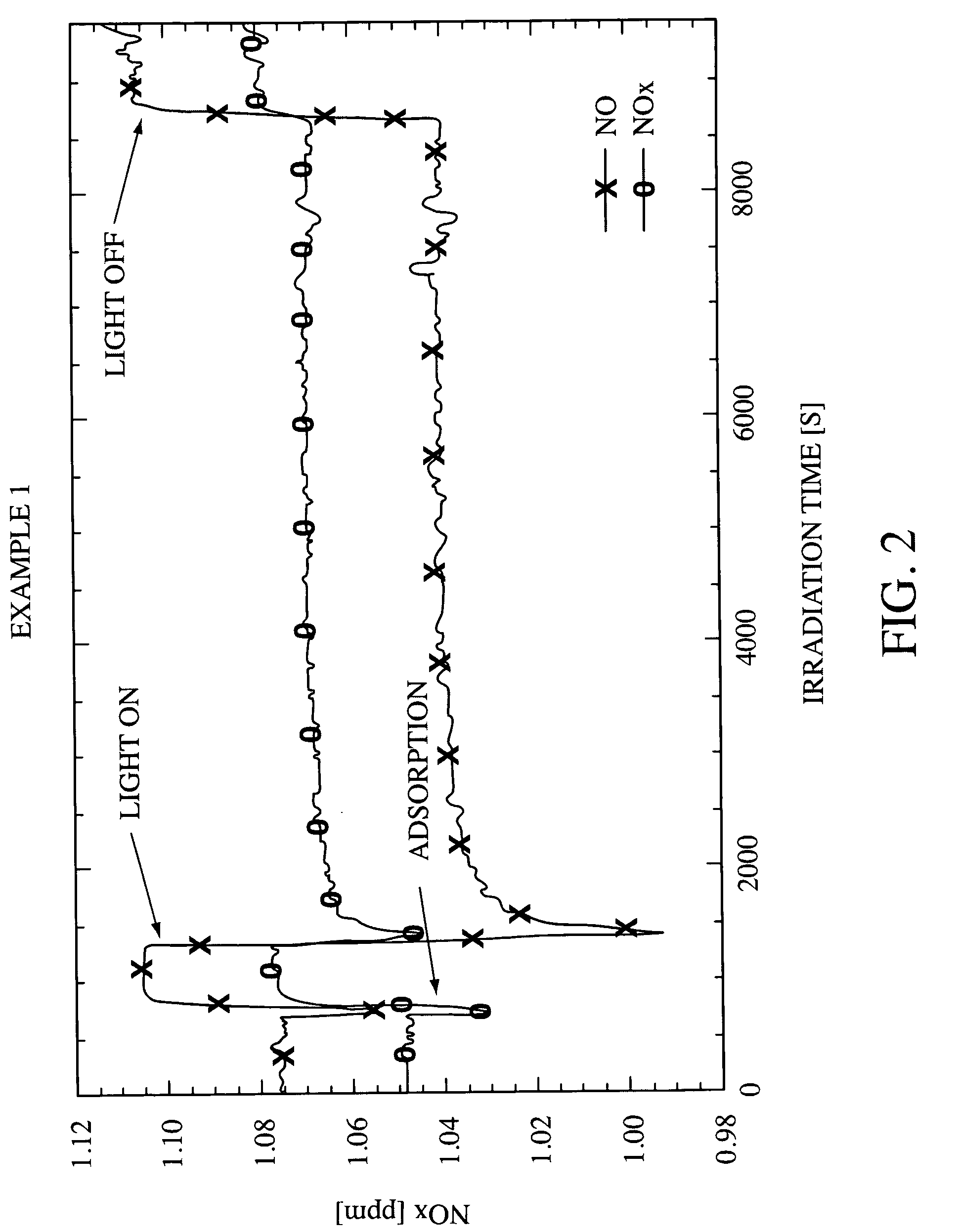

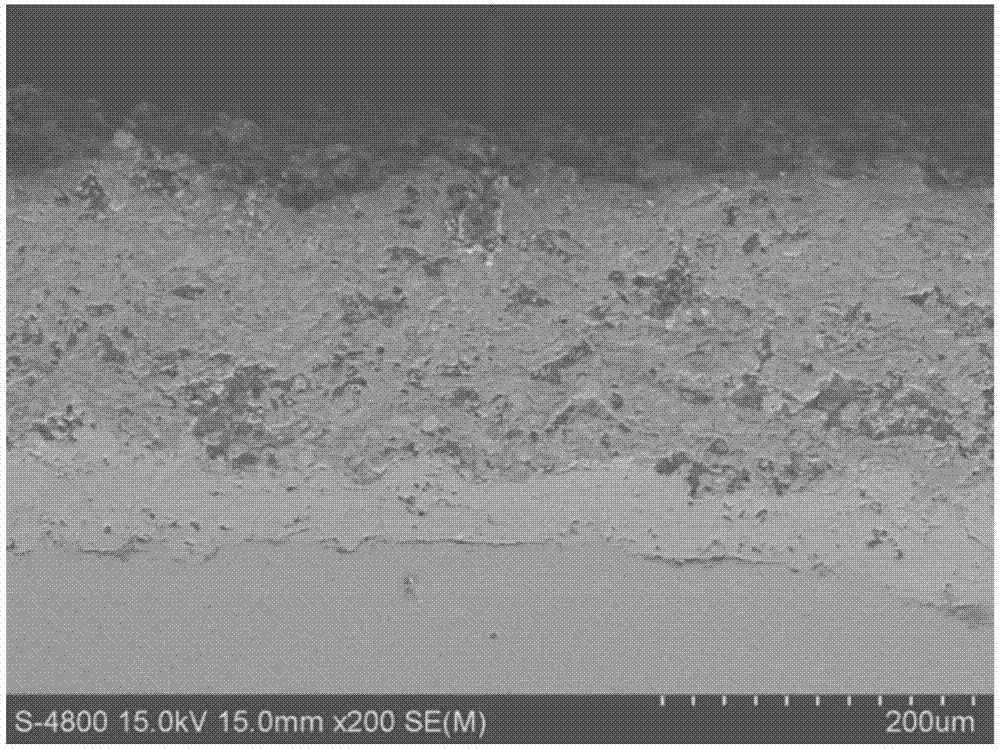

Photocatalytically activated structural components composed of a matrix bound with a mineral binder, as well as method for production of the structural components

InactiveUS20100242806A1Reduce intensityLoss in strengthGas treatmentMouldsActive particlesMatrix bound

A structural component on the basis of a mineral, crystalline binder matrix composed of hardened cement and / or construction lime and / or gypsum, wherein the matrix can have aggregates and / or additives and / or admixtures, forms a surface that receives light, in its usability or use, on which surface photocatalytically active particles are situated. The particles are situated and fixed in place only on the surface of the structural component. The remainder of the structural component body does not have the particles. A method for production of the structural components is also provided.

Owner:DYCKERHOFF

Preparation method of tantalum boride composite coating

InactiveCN107287547AHighlight substantive featuresHigh densityMolten spray coatingThermal sprayingBoron carbide

The invention discloses a preparation method of a tantalum boride composite coating, and relates to coating of boride to metal materials. The tantalum boride composite coating is obtained through the thermal spraying in-situ reaction in a synthesis manner. The preparation method comprises the steps of preparing tantalum oxide / boron carbide / aluminum composite powder for thermal spraying, carrying out pretreatment on the surface of a matrix material needing the coating and preparing the tantalum boride composite coating. According to the preparation method, the defects that a tantalum boride composite coating prepared in the prior art is complex in preparation process, high in cost, large in pollution, low in deposition efficiency, small in coating thickness, small in coating density, poor in uniformity, low in toughness, poor in coating and matrix binding force, prone to cracking and not suitable for being applied to large-scale industrial production are overcome.

Owner:HEBEI UNIV OF TECH

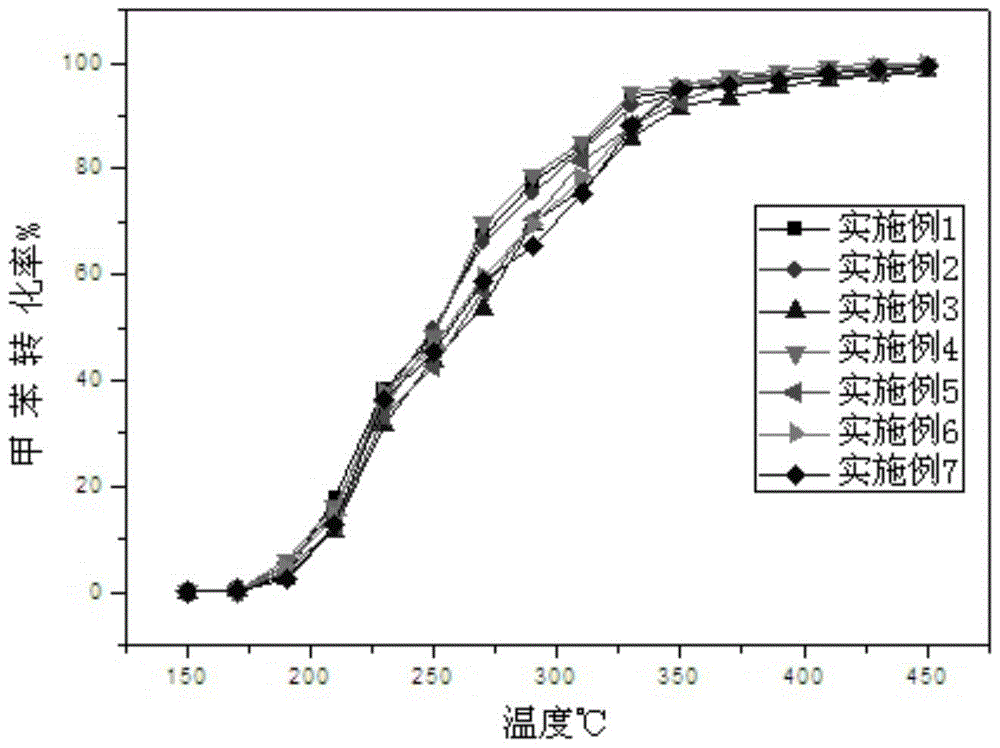

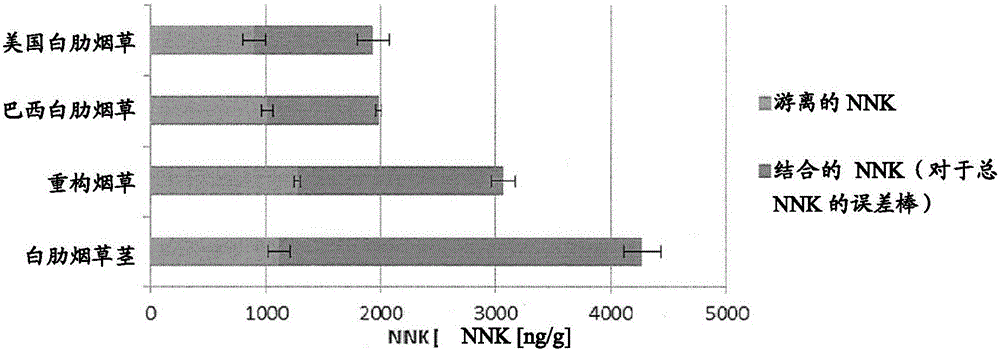

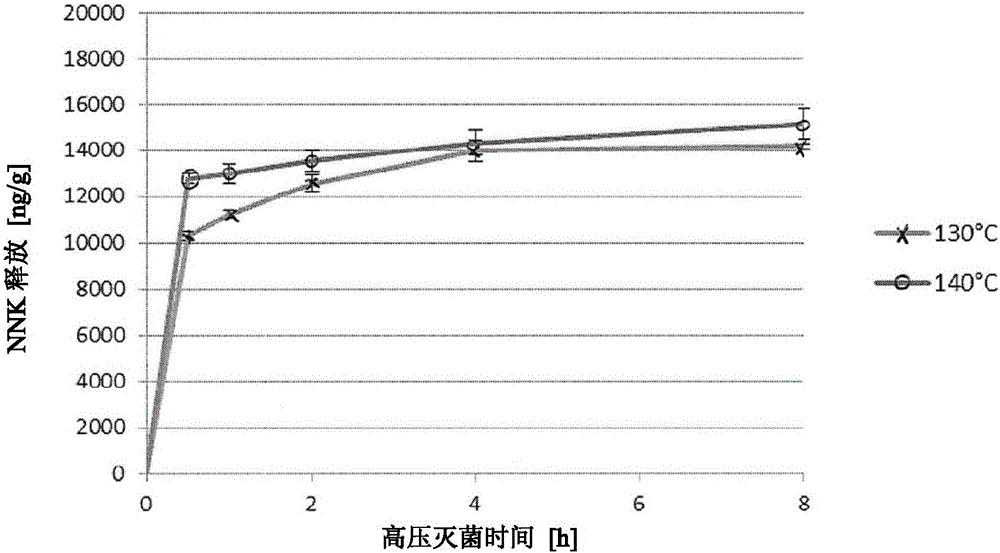

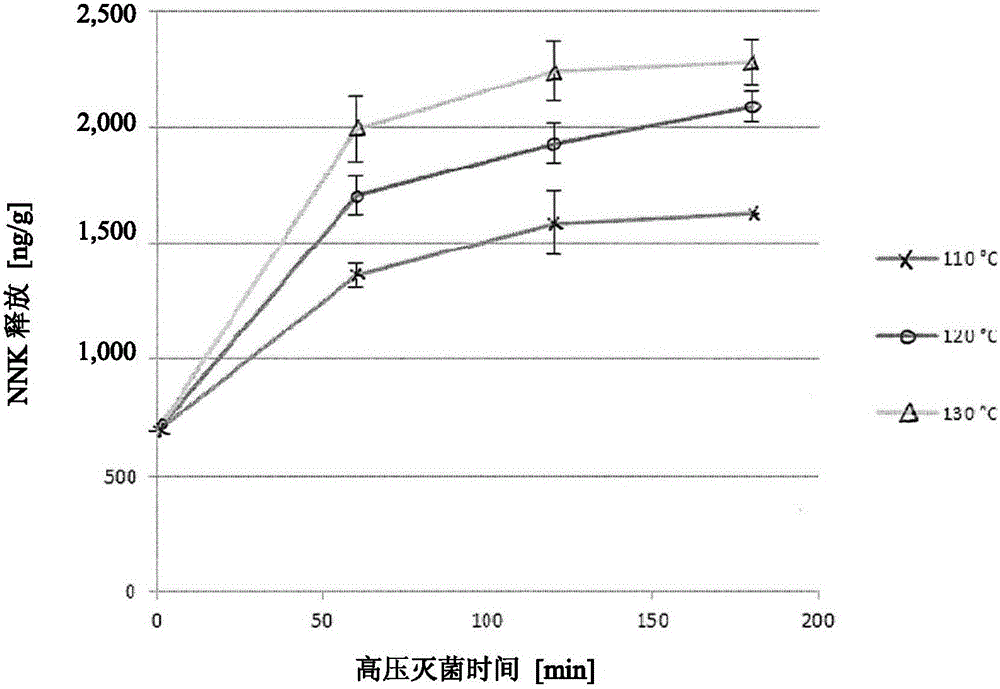

Methods for reducing one or more tobacco specific nitrosamines in tobacco material

ActiveCN105142429ALess quantityTobacco treatmentMaterial analysisTobacco-specific nitrosaminesCelsius Degree

Owner:PHILIP MORRIS PROD SA

Affinity separation methods and systems

InactiveUS20100129889A1Peptide/protein ingredientsSolid sorbent liquid separationAffinity matrixMatrix bound

An affinity matrix comprising a base matrix containing biotin; and a fusion protein attached to the base matrix, wherein the fusion protein contains a matrix binding element capable of binding to the base matrix via biotin and a target binding element capable of binding, or being bound by, at least one target component.

Owner:INNOVATIVE PURIFICATION TECH

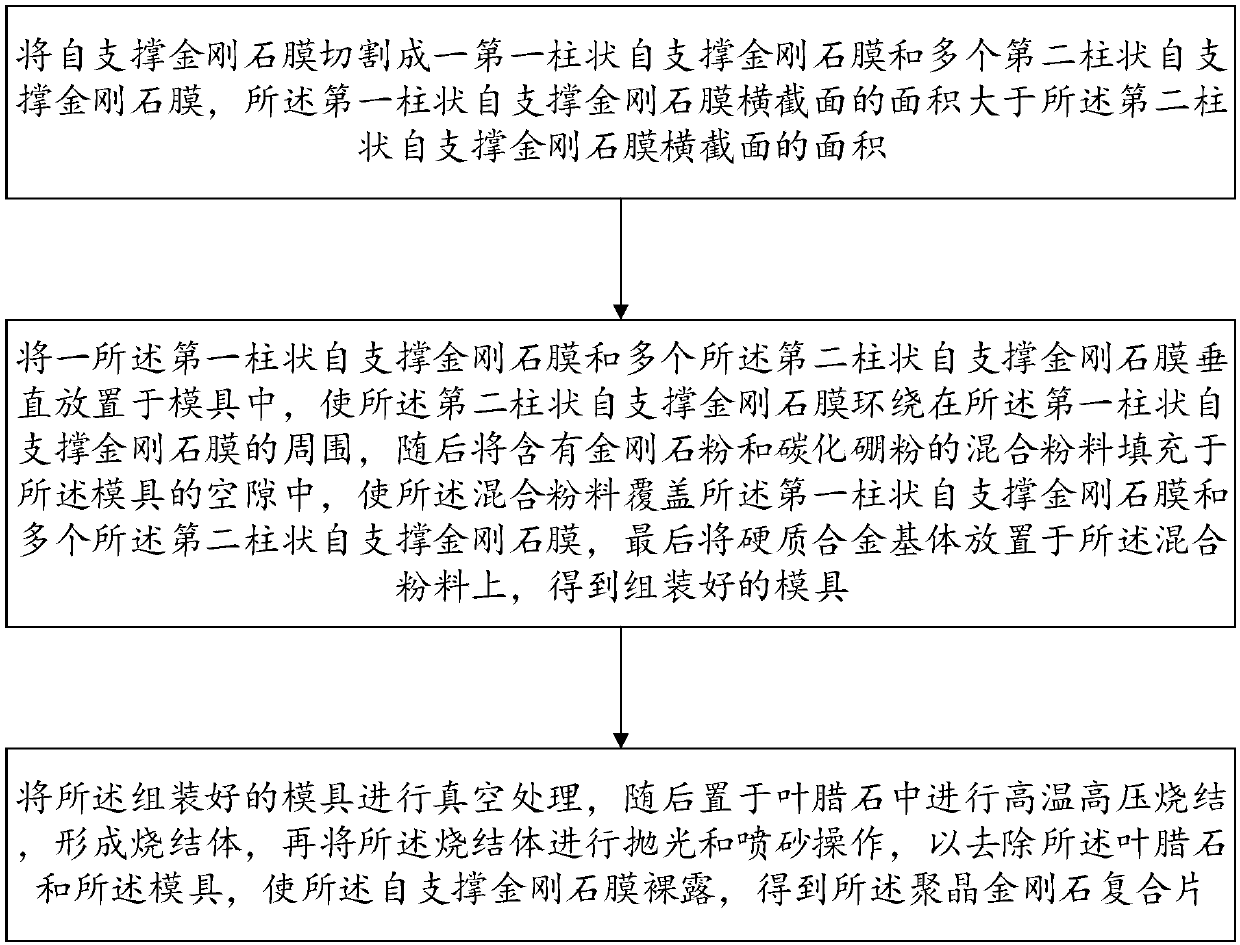

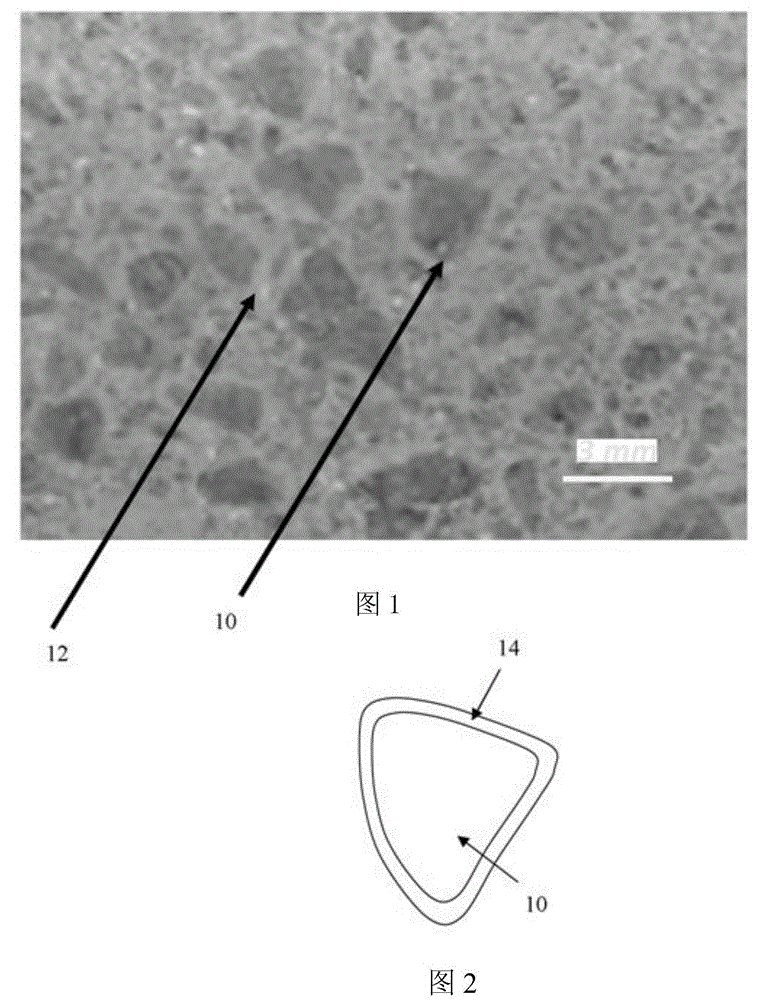

Polycrystalline diamond clad sheet and preparation method thereof

PendingCN107867016AImprove impact resistanceImprove heat resistanceMetal layered productsBoron carbidePolycrystalline diamond

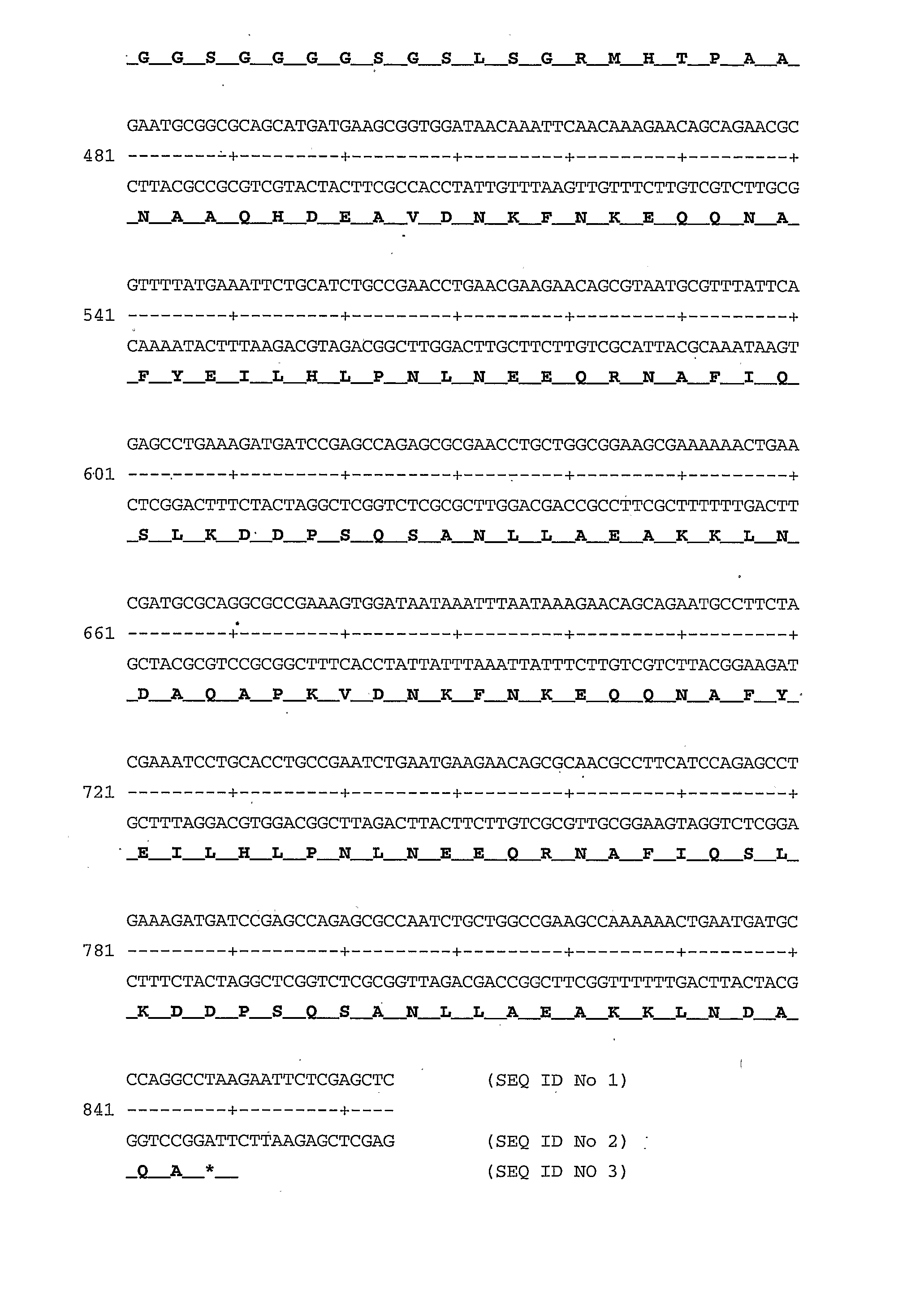

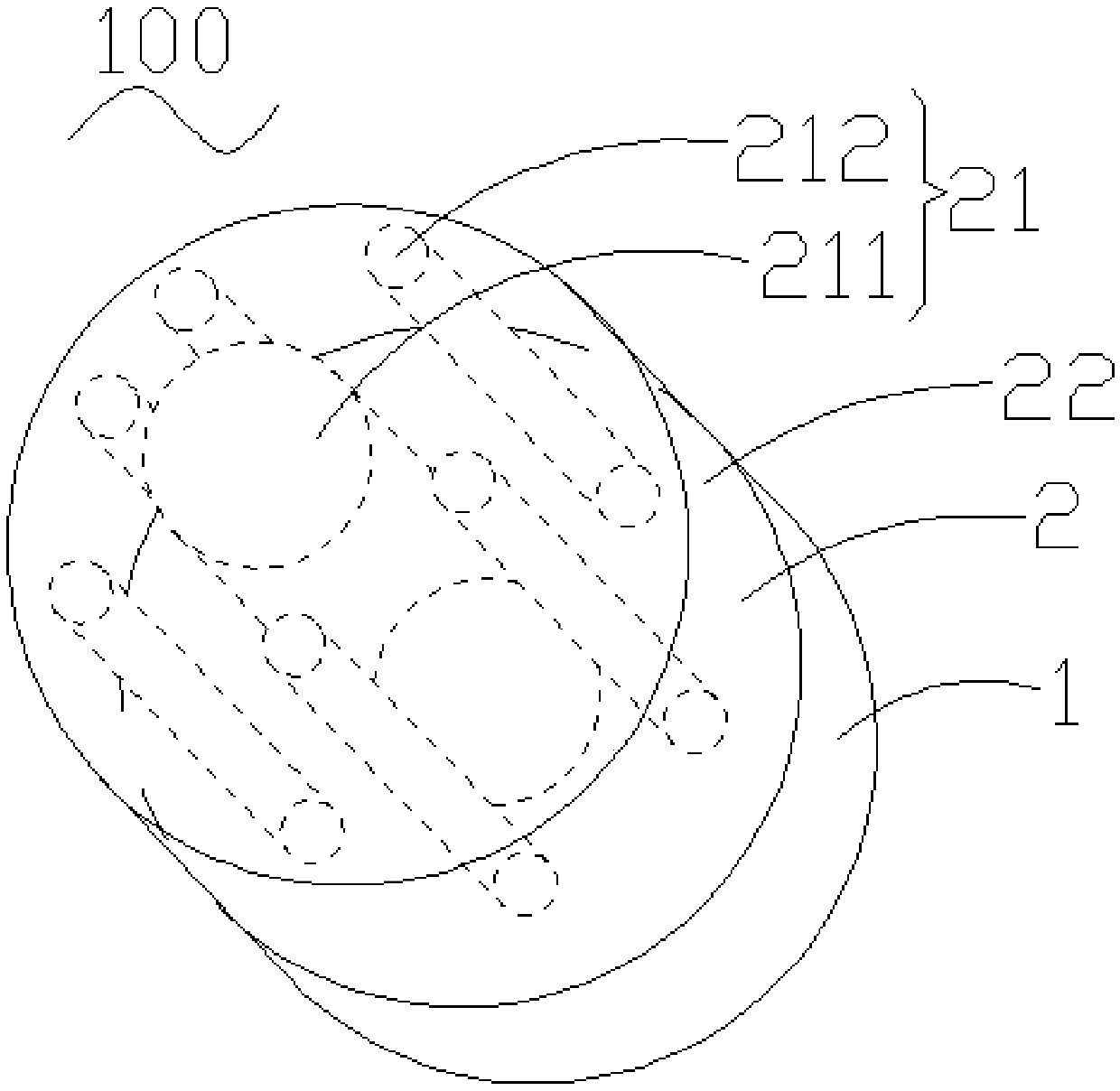

The invention provides a polycrystalline diamond clad sheet which comprises a hard alloy matrix and a polycrystalline diamond layer arranged on the hard alloy matrix, wherein the polycrystalline diamond layer comprises a self-supporting diamond film and mixed powder; the self-supporting diamond film comprises a first columnar self-supporting diamond film and multiple second columnar self-supporting diamond films distributed around the first columnar self-supporting diamond film; the first columnar self-supporting diamond film and the second columnar self-supporting diamond films are perpendicularly arranged on the surface of the hard alloy matrix; the area of the cross section of the first columnar self-supporting diamond film is larger than that of the cross section of each second columnar self-supporting diamond film; the mixed powder is uniformly dispersed around the first columnar self-supporting diamond film and the second columnar self-supporting diamond films; and the mixed powder comprises diamond powder and boron carbide powder. The polycrystalline diamond clad sheet provided by the invention is excellent in heat conductivity, impact resistance, film matrix binding force and wear resistance.

Owner:SHENZHEN INST OF ADVANCED TECH

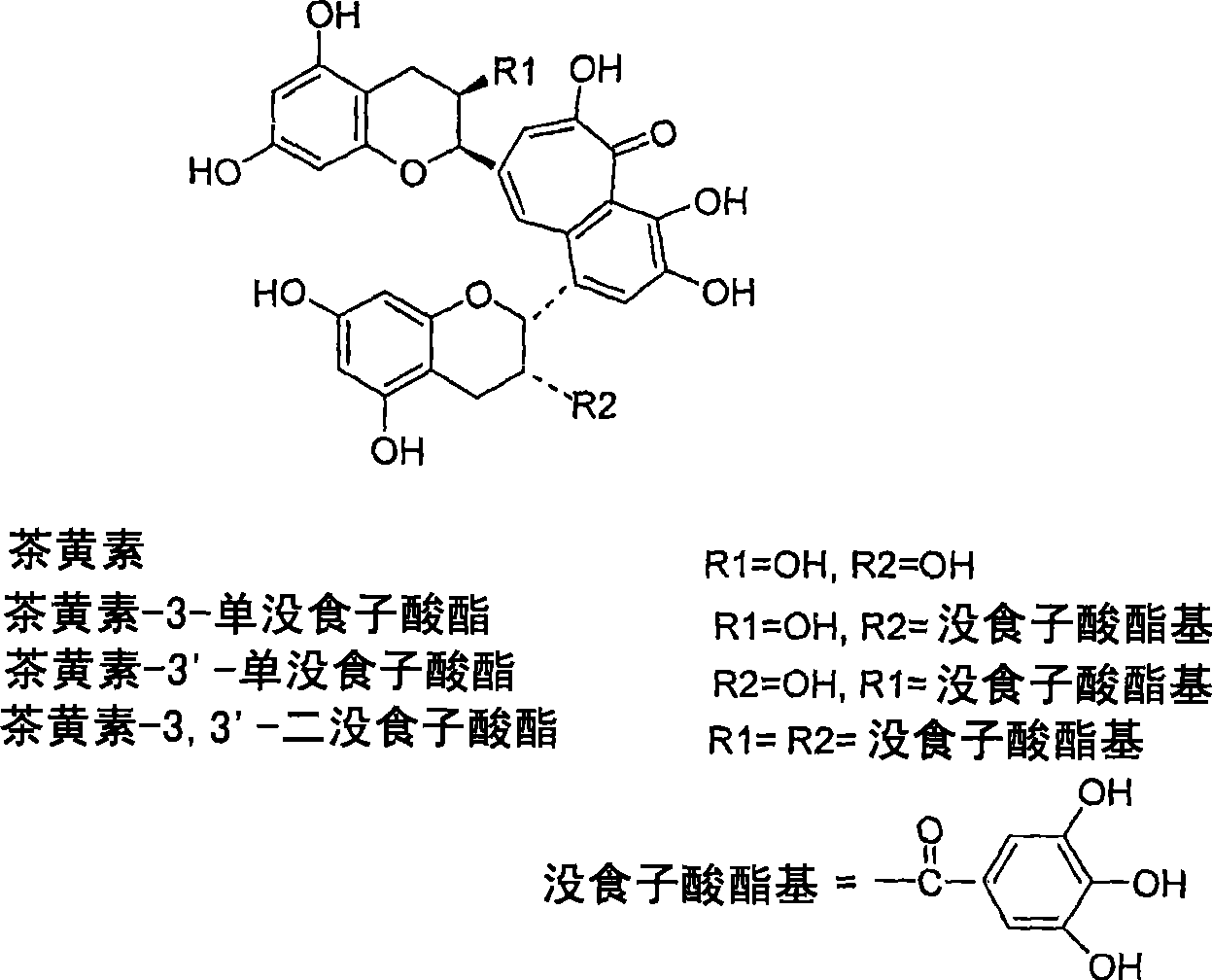

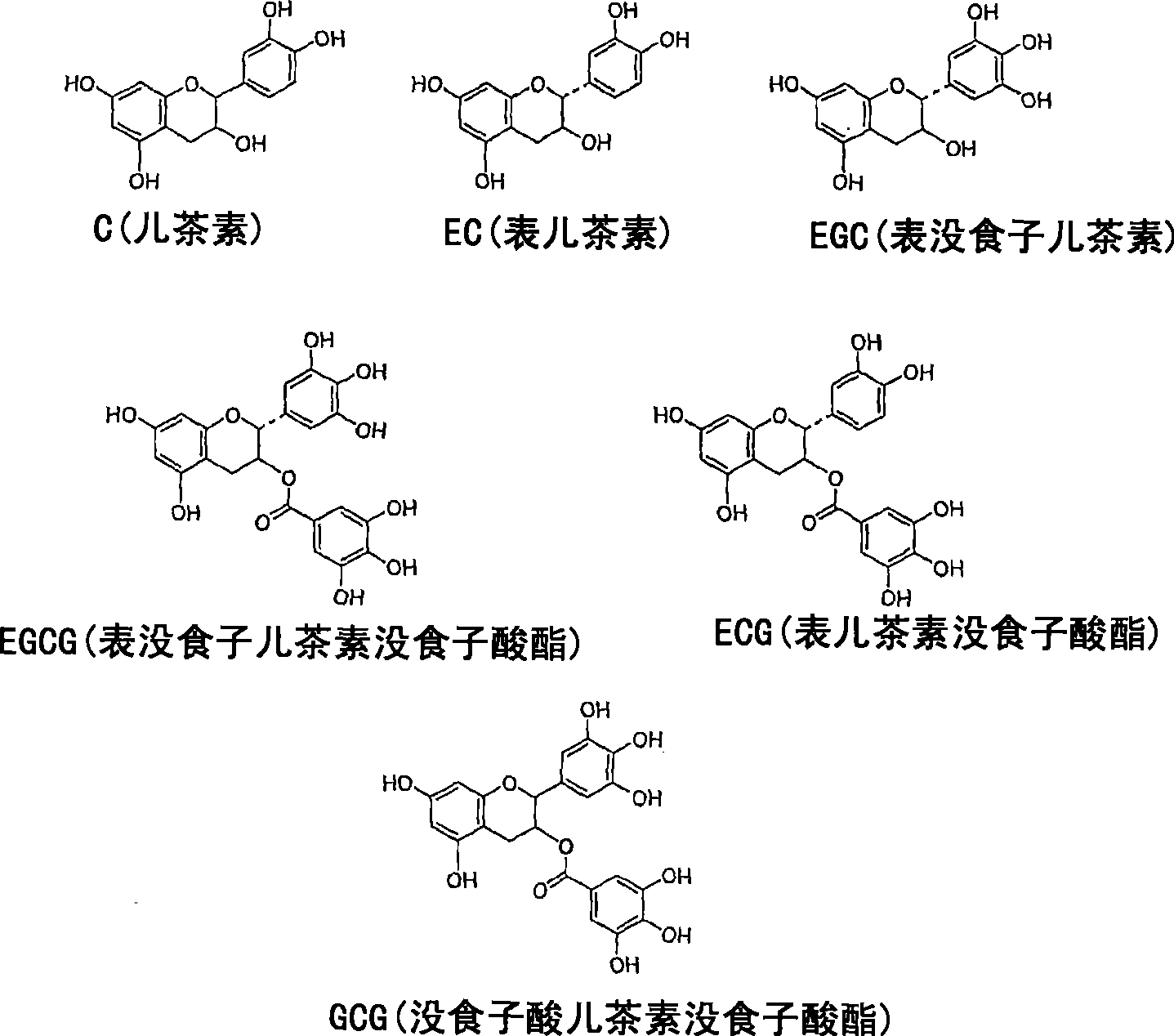

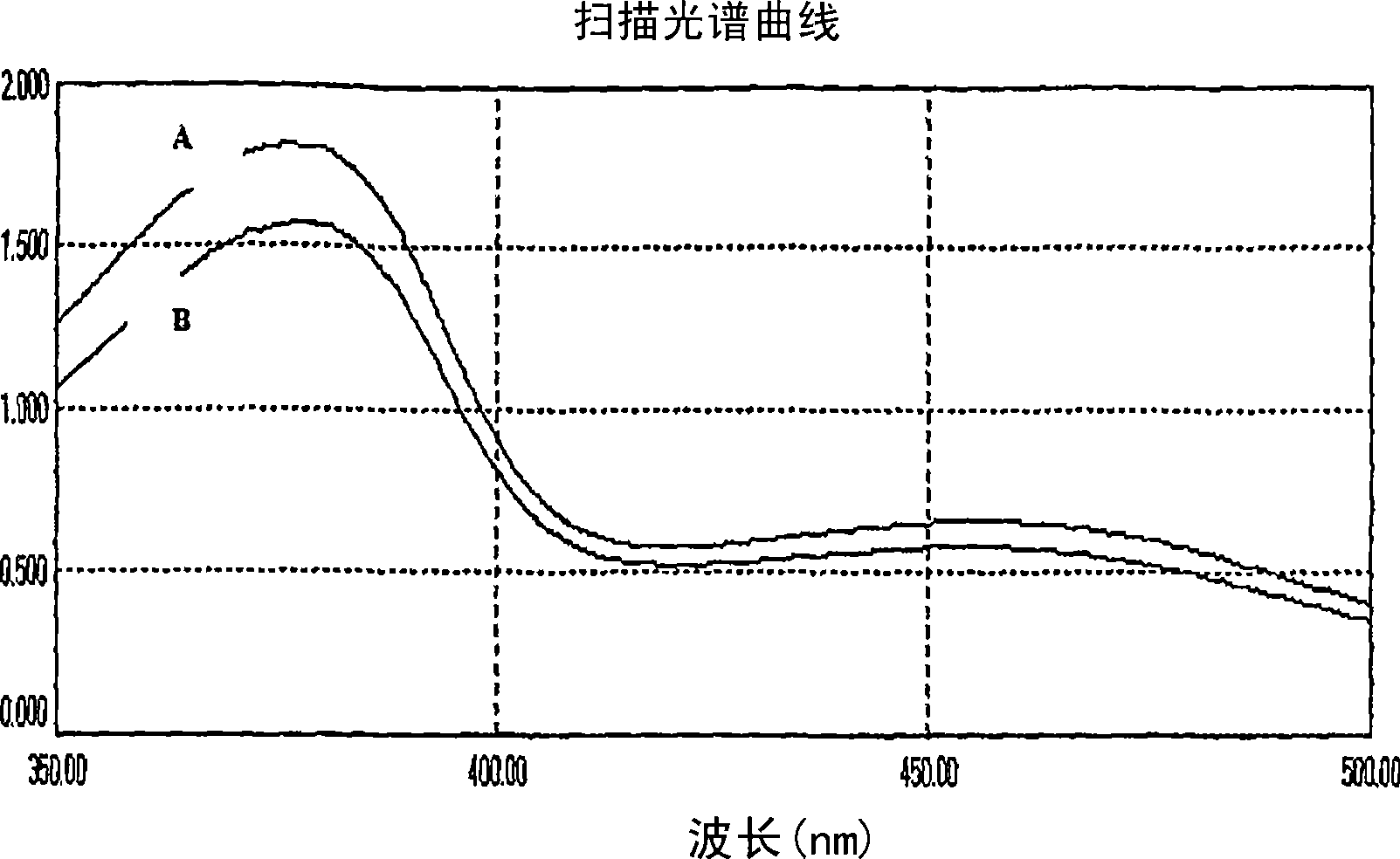

A solid state matrix, process of preparation thereof, and process of preparation of theaflavins

The present invention relates to a process for the development of a highly efficient solid state matrix by the activation of acrylate based polymer resin having specialized functional groups with 1,1-Carbonyl diimidazole for immobilizing biologically active macromolecules such as oxidases, in particular plant oxidases and the most preferred being tea polyphenol oxidase through indirect covalent bonding / cross linking on such activated polymer resin support, are thermally stable, gives very high number of turnovers in vitro ('n' times); with tea substrate forming exclusive product Theaflavins without any loss of biological activity and leaving the product remaining in vitro without adherence to matrix rendering the matrix safe towards product poisoning and subsequent partial or complete loss of biological activity of the matrix bound enzyme system and thus well adapted to and well suited bioreactors based on such systems. It is unique with respect to its recyclability of otherwise uneconomical tea substrates such as seed and flower substrates into theaflavins both with respect to crude substrate or purified ones.

Owner:COUNCIL OF SCI & IND RES

Preparation method of Cr-doped DLC coating

InactiveCN110306153AImprove uniformityHigh densityVacuum evaporation coatingSputtering coatingDlc coatingBinding force

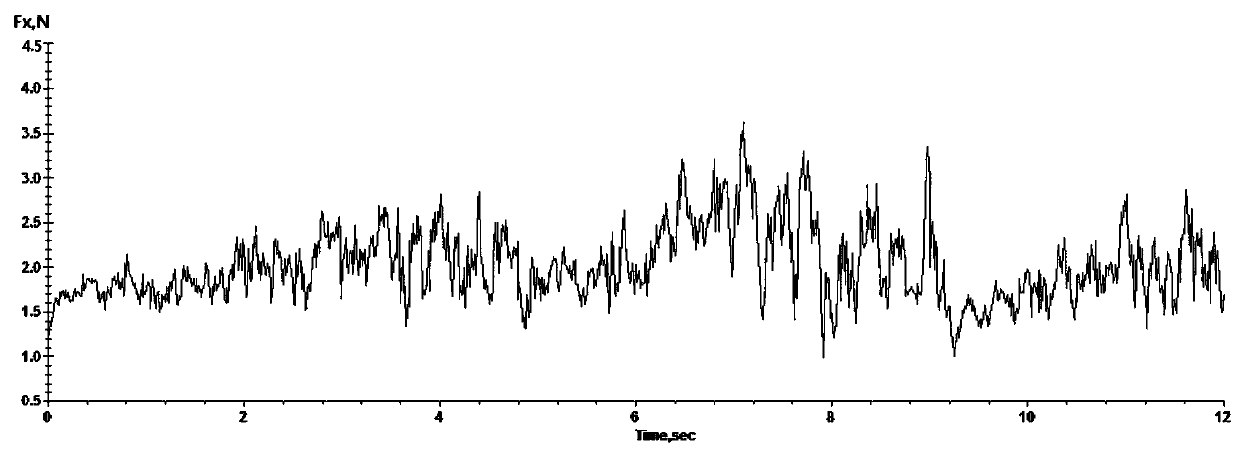

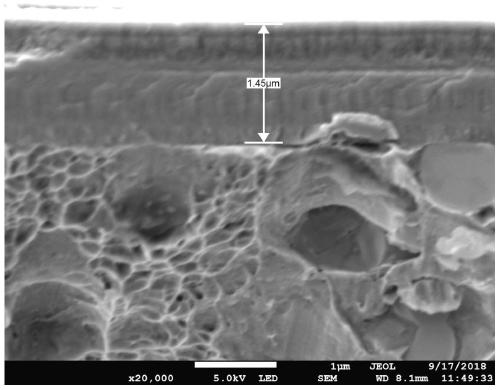

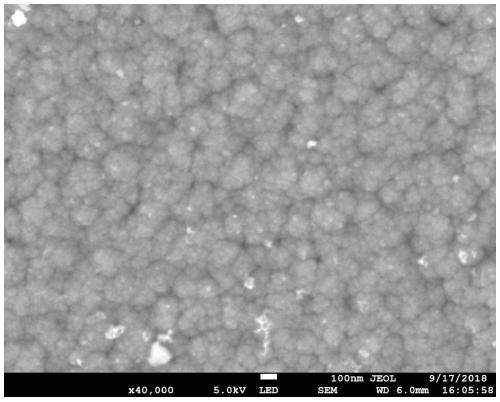

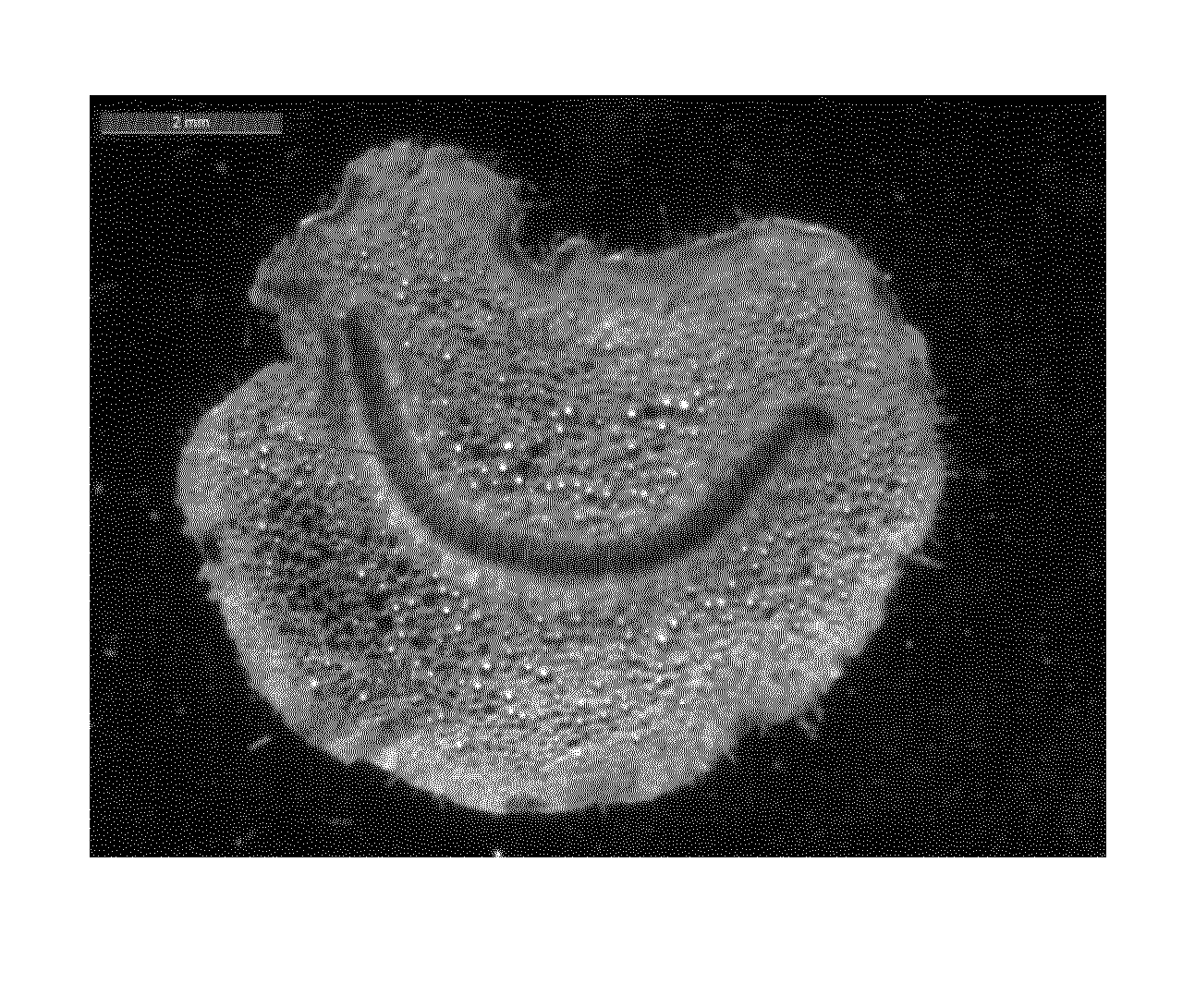

The invention discloses a preparation method of a Cr-doped DLC coating. The advantages that the smoothness, uniformity and density of a high-power pulse magnetron sputtering film layer are high are sufficiently utilized, and a bottom layer and transition layer design method is adopted in order to overcome the defects that the binding force of the DLC coating and the toughness of the film layer arepoor. By means of the unique film system design and mixing process, it is guaranteed that the binding force of the coating is improved, and it is also guaranteed that the coating deposition rate, thecoating density and the wear resisting and friction reducing performance are improved. The appearance of the Cr-doped DLC coating prepared through the method is ash black, the surface is smooth and dense, the hardness of the coating is 32 GPa, the film-matrix binding force reaches 72 N, and the coating thickness is 1.45 micrometers. The dry friction coefficient of the coating is 0.2. It is shownthat the Cr-doped DLC coating has good wear resisting and friction reducing performance.

Owner:HENAN UNIV OF SCI & TECH

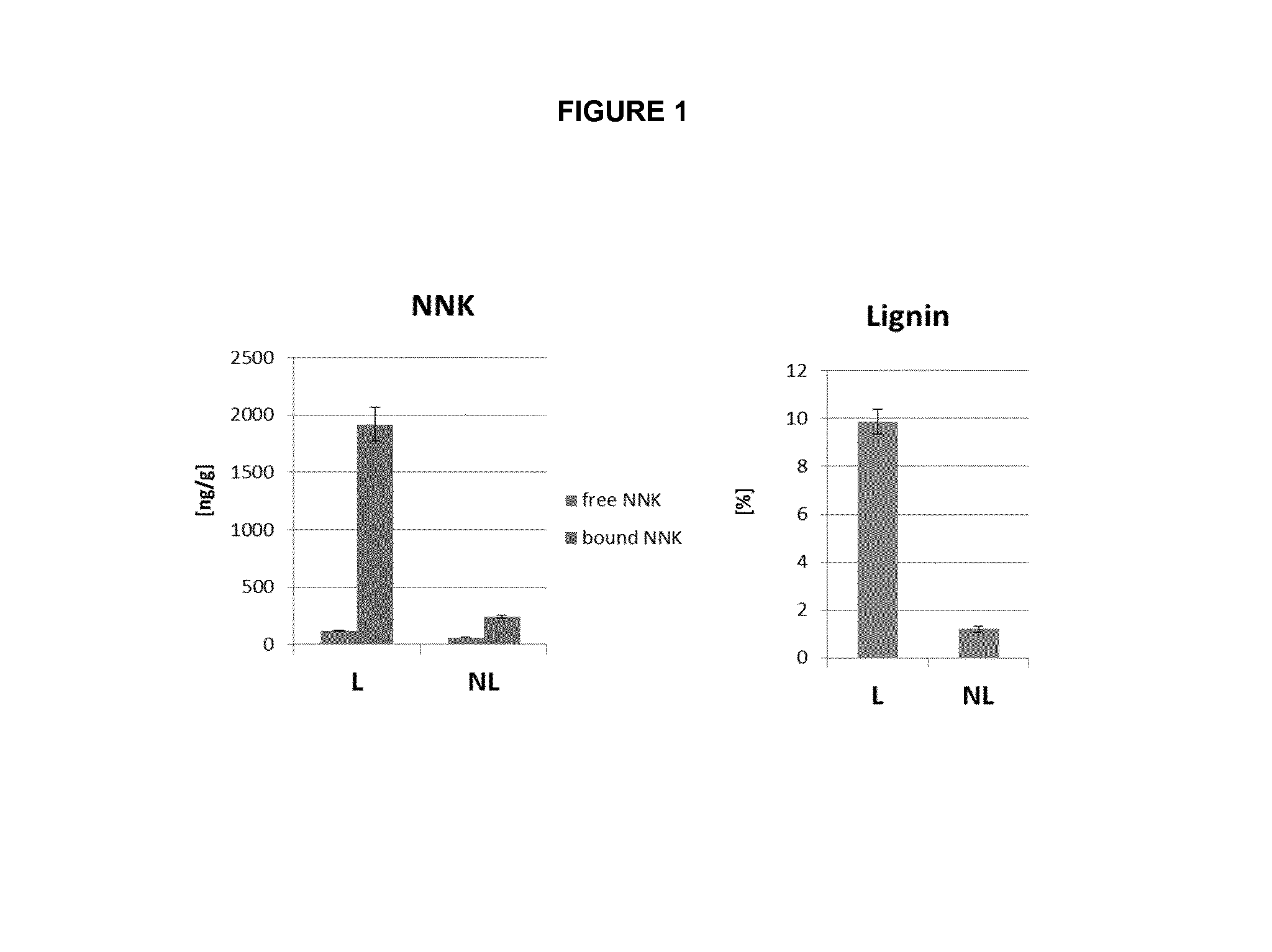

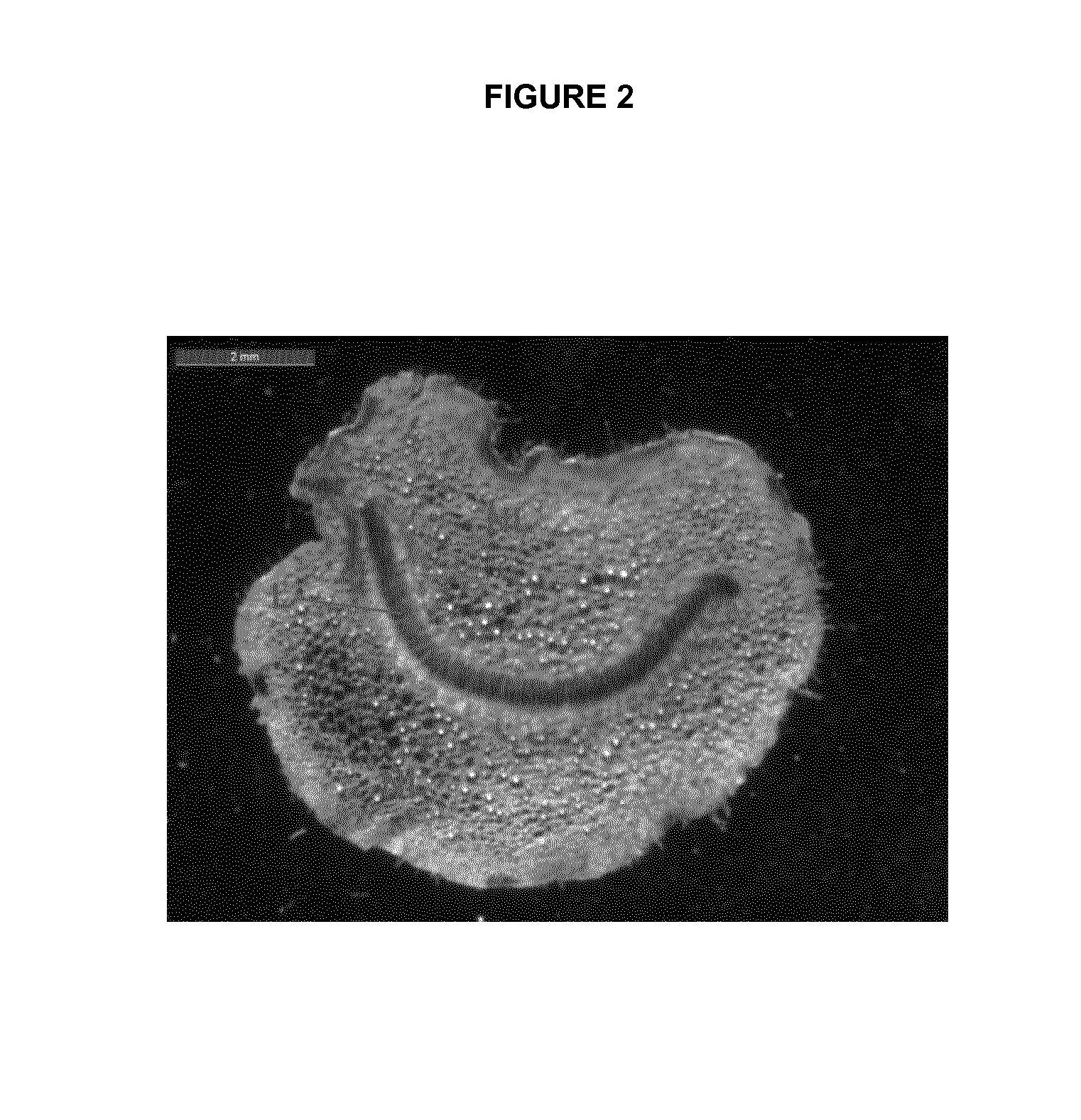

Methods for reducing matrix-bound nicotine-derived nitrosamine ketone in tobacco plant material

InactiveUS20160295907A1Reduce formationReduce the amount requiredTobacco preparationTobacco treatmentEngineeringTobacco processor

A method of reducing the amount of matrix-bound NNK in cured tobacco plant material is provided comprising reducing the amount of lignin in the cured tobacco plant material. A further method of reducing the formation of matrix-bound NNK during the curing of tobacco plant material is described comprising reducing the amount of lignin therein prior to curing.

Owner:PHILIP MORRIS PROD SA

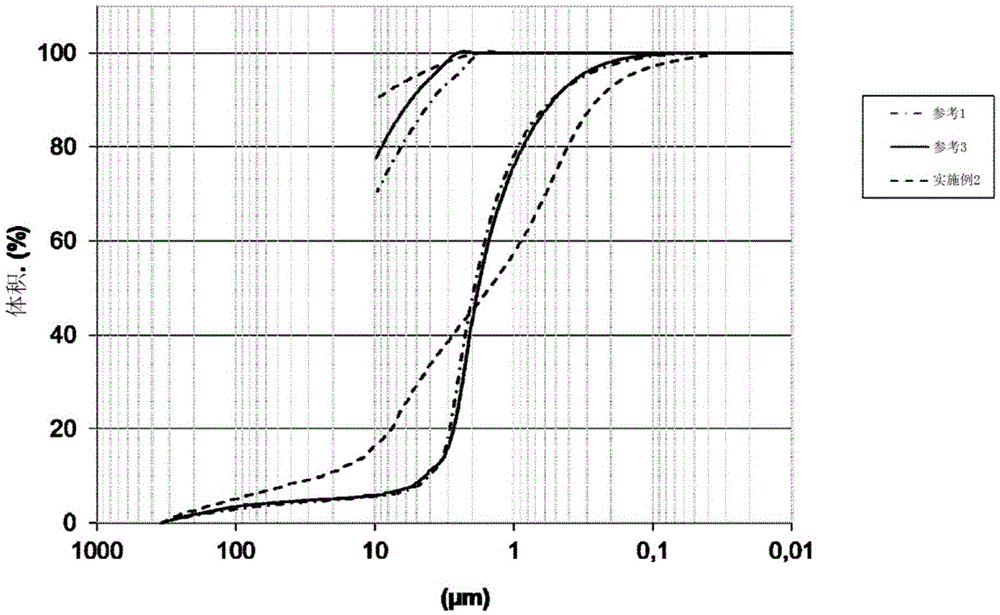

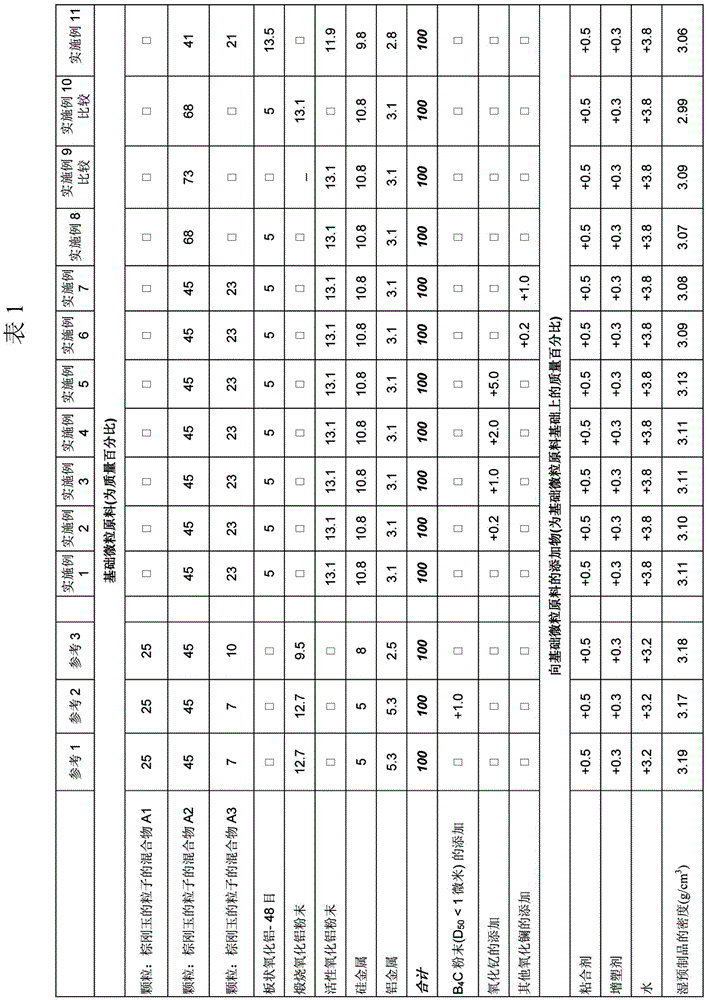

Refractory product with a SiAiON matrix

ActiveCN105593192AExcellent heat cycle resistanceAccelerated corrosionFurnace componentsMetallurgyMaximum size

A sintered refractory product consisting of: a granulate consisting of all the particles having a size larger than 100 [mu]m, or "grains", the granulate representing between 55% and 85% by mass of the product, the maximum size of the grains being smaller than 3.5 mm, and a matrix binding said grains and consisting of the particles having a size smaller than or equal to 100 [mu]m, or "fine particles", said matrix comprising at least one crystallised SiAlON phase of formula SixAlyOuNv, in which x is greater than or equal to 0, greater than 0.05, greater than 0.1 or greater than 0.2, and less than or equal to 1, less than or equal to 0.8 or less than or equal to 0.4; y is greater than 0, or greater than 0.1, greater than 0.3 or greater than 0.5, and less than or equal to 1; u is greater than or equal to 0, greater than 0.1 or greater than 0.2, and less than or equal to 1 or less than or equal to 0.7; v is greater than 0, greater than 0.1, greater than 0.2 or greater than 0.5, or greater than 0.7, and less than or equal to 1; at least one of stoichiometric indices x, y, u and v being equal to 1, the volume of the fraction of the pores having a size of between 10 and 100 microns being greater than 4% of the total volume of pores.

Owner:圣戈班研究中心与欧洲研究院

Diamond film containing chronium and its preparing method

InactiveCN100387754CHigh hardnessImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyPulsed DC

This invention discloses a diamond film containing Cr and its preparation method. Said film is a H-free film containing Cr deposited in gas phase on a matrix surface having the alternative condensed multi-layer gradient structure of Cr, CrNx, CryCz, Cr, CrNx, CryCz layers orderly from inside to outside along the vertical direction of the matrix surface, the film thickness is not less than 2 mum, which has a fine film / matrix binding force and good wearability. The preparation method includes utilizing the magnet control sputtering system to coat, the magnet control targets are a pair of unbalanced magnet controlled Cr targets and 1-4 pairs of un-balanced magnet controlled C targets, the supply of which is 20-250KHz IF AC supply, a pulse matrix negative bias voltage is applied on the armed coating matrix by single-level pulse DC supply, the sputtering gas is Ar.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Waterproof paint for river channel dredging equipment

InactiveCN109735197AImprove bindingImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsALUMINUM STEARATESMetallic materials

The invention discloses waterproof paint for river channel dredging equipment. The waterproof paint comprises, by weight, matrix resin, organic silicon resin, methyl vinyl silicone rubber, inositol hexaphosphate, glycerin monostearate, sodium dodecyl sulfate, butyl-hydroxy polyurethane, zinc oxide, dibasic lead phosphite, calcium carbonate, aluminum stearate, silicon nitride, n-butanol, tricarboxylic methylpropane, nanometer graphene, magnesium oxide, boron nitride, borosilicate glass powder, talc powder, titanium dioxide, zeolite, lac, carbon black, silicone oil and deionized water. The waterproof paint has the advantages that the waterproof paint is high in metallic matrix binding force, and the adhesion, the leveling properties and the mechanical properties of coatings can be effectively improved; the waterproof paint is good in corrosion resistance and leveling property, the foamed coatings are high in metallic matrix binding capacity and flatness and difficult to peel or crack andhave smooth surfaces, good waterproof and anticorrosion effects can be realized, and the waterproof paint is high in environmental weather resistance and suitable to be used for the river channel dredging equipment.

Owner:临泉县凯晟建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com